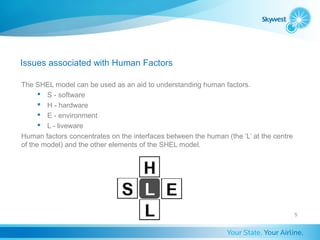

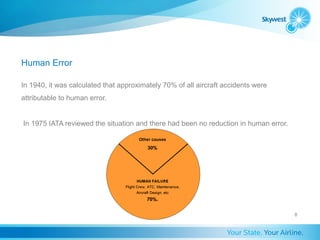

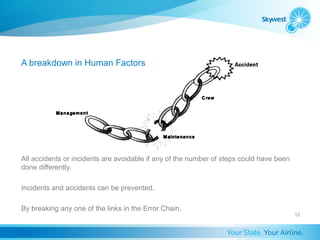

Human factors is the study of how human capabilities and limitations impact safety and efficiency in the workplace, especially aircraft maintenance. Several air accidents have been caused by human error in maintenance. To improve safety, the aviation industry must understand how factors like personnel, equipment, procedures, and environment interact and optimize that relationship. This includes considering physiology, psychology, workplace design, and the interface between humans and machines. Understanding human factors can help reduce errors by improving training, procedures, tools, and inspections. About 70% of early aircraft accidents were due to human error, and maintenance deficiencies remain a major cause today due to issues like staff shortages, time pressures, and failures to follow approved procedures. Reducing human error requires recognizing risks and