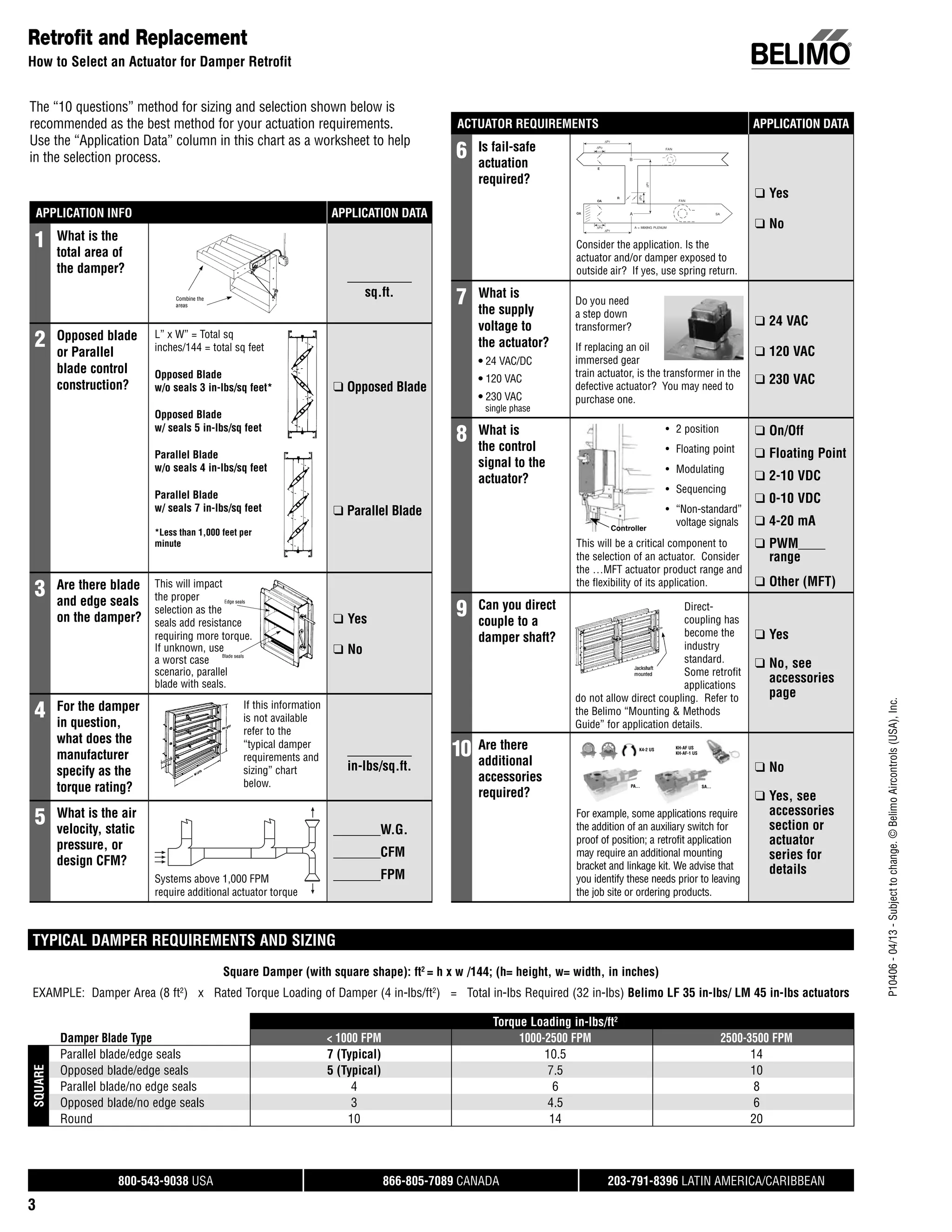

The document provides a 10-step method for selecting an actuator for damper retrofit applications. It includes tables to help determine the necessary actuator specifications based on the damper size, type, torque requirements, control inputs, and other application details. An example calculation is also provided to demonstrate how to size an actuator for a specific damper retrofit project.