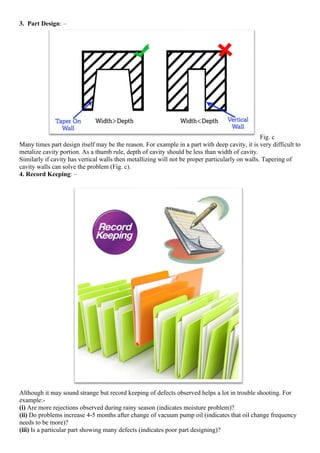

The document discusses common defects in metallizing, such as burned parts, Newton fringe, iridescence, spatter, and shadowing, highlighting their causes and potential solutions. It emphasizes the importance of maintaining proper vacuum levels, using quality materials, and employing general precautions like dust and moisture reduction to minimize defects. Additionally, it suggests that systematic record-keeping can aid troubleshooting and improve the metallizing process.