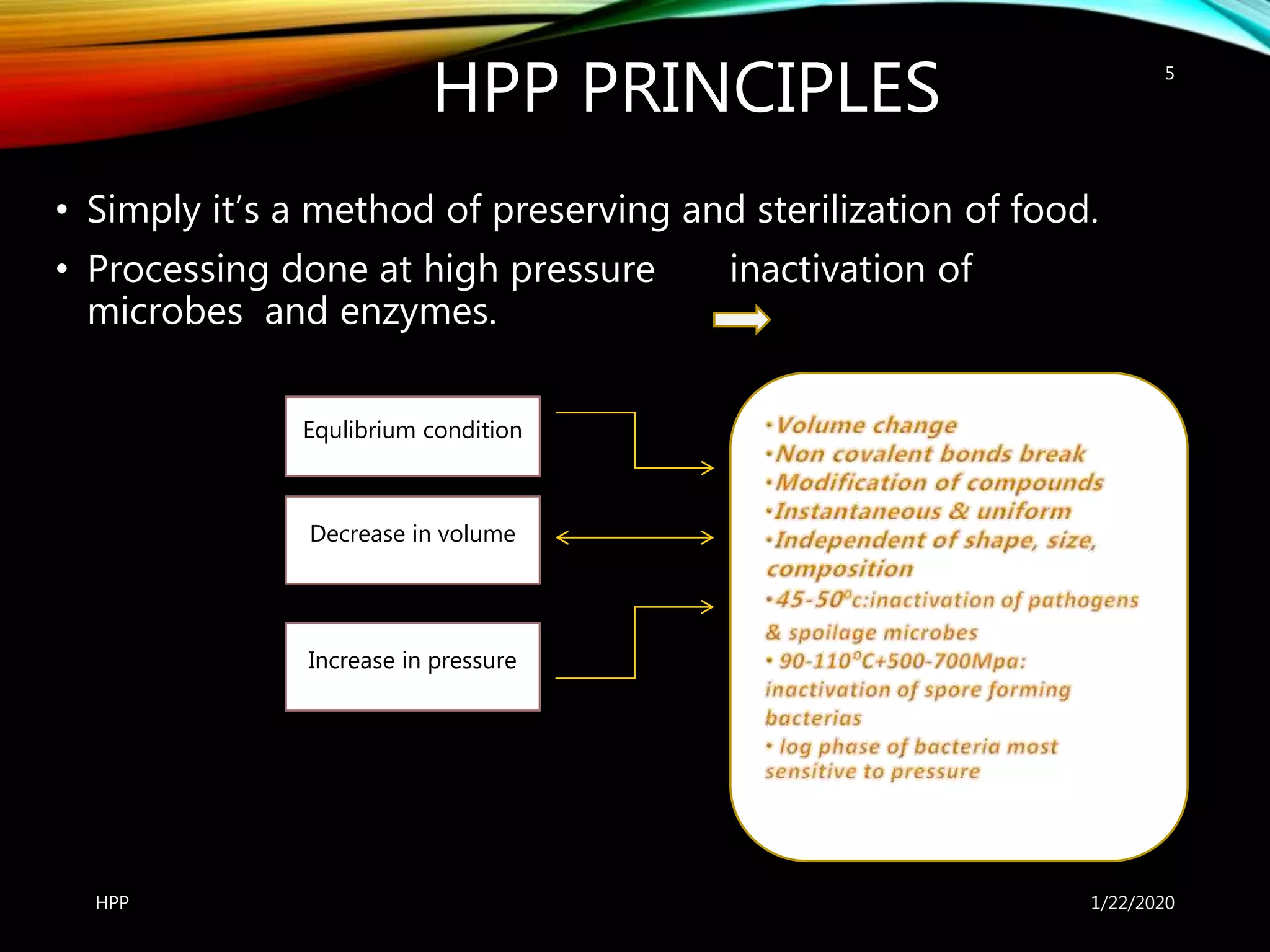

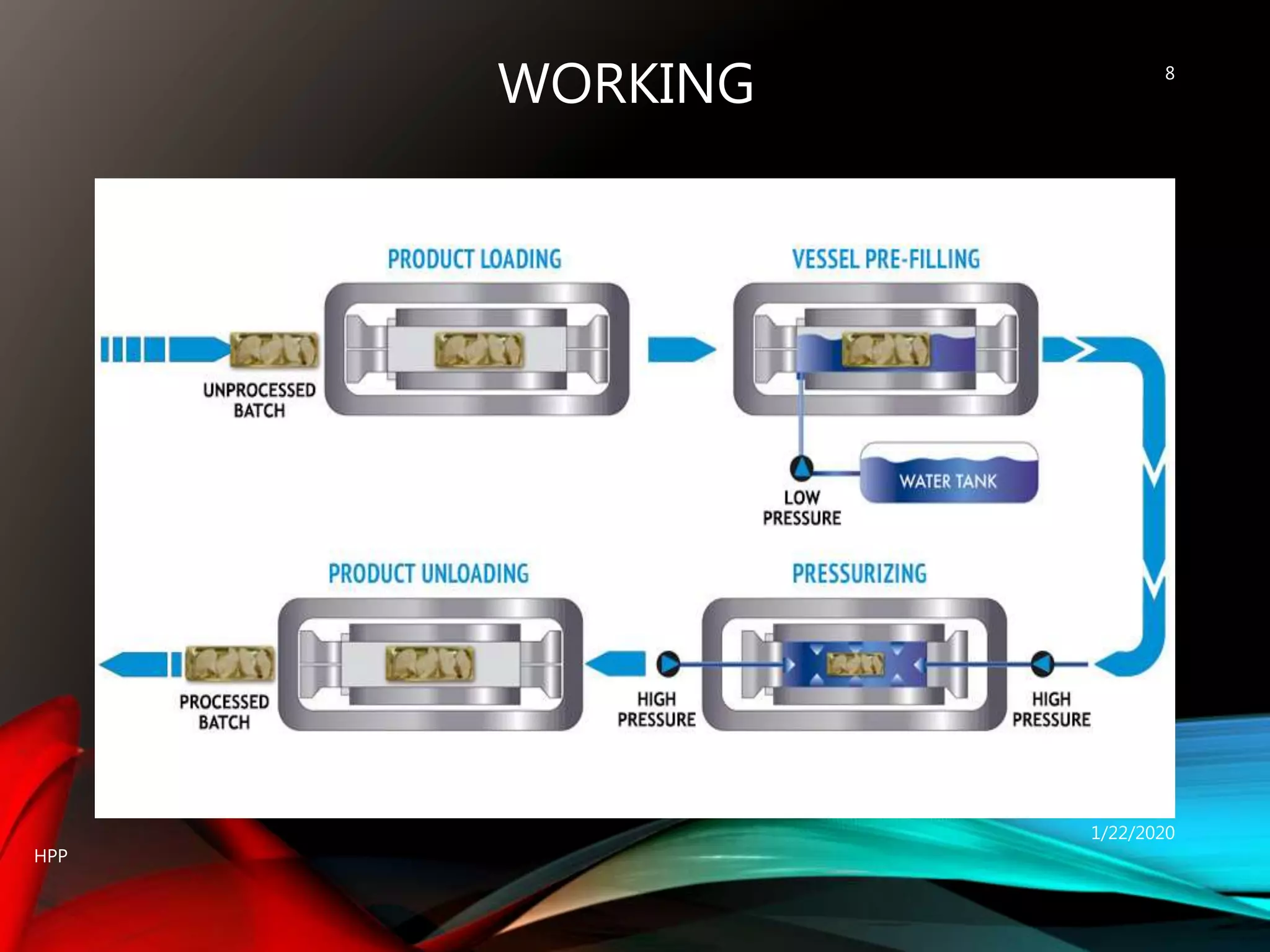

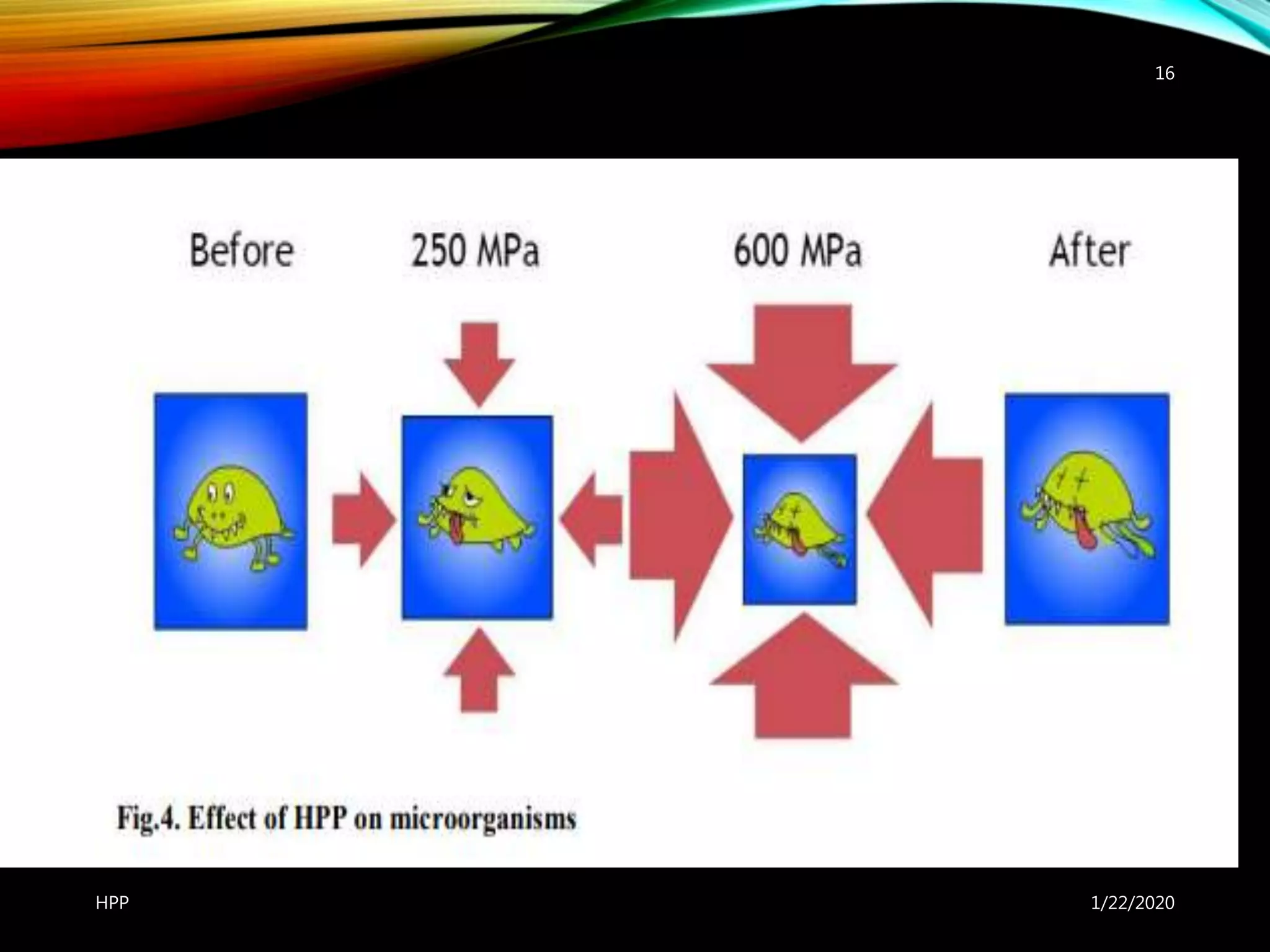

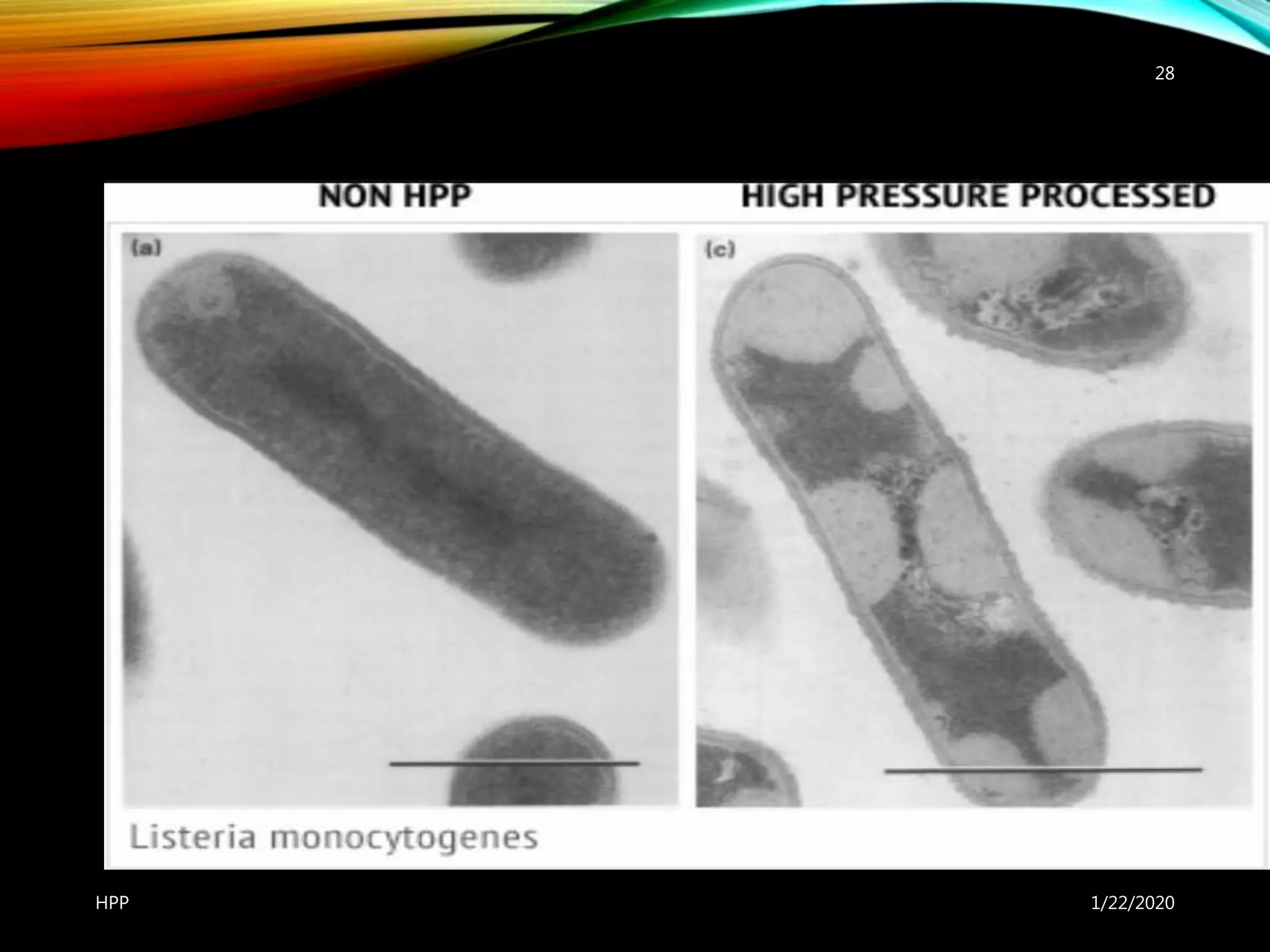

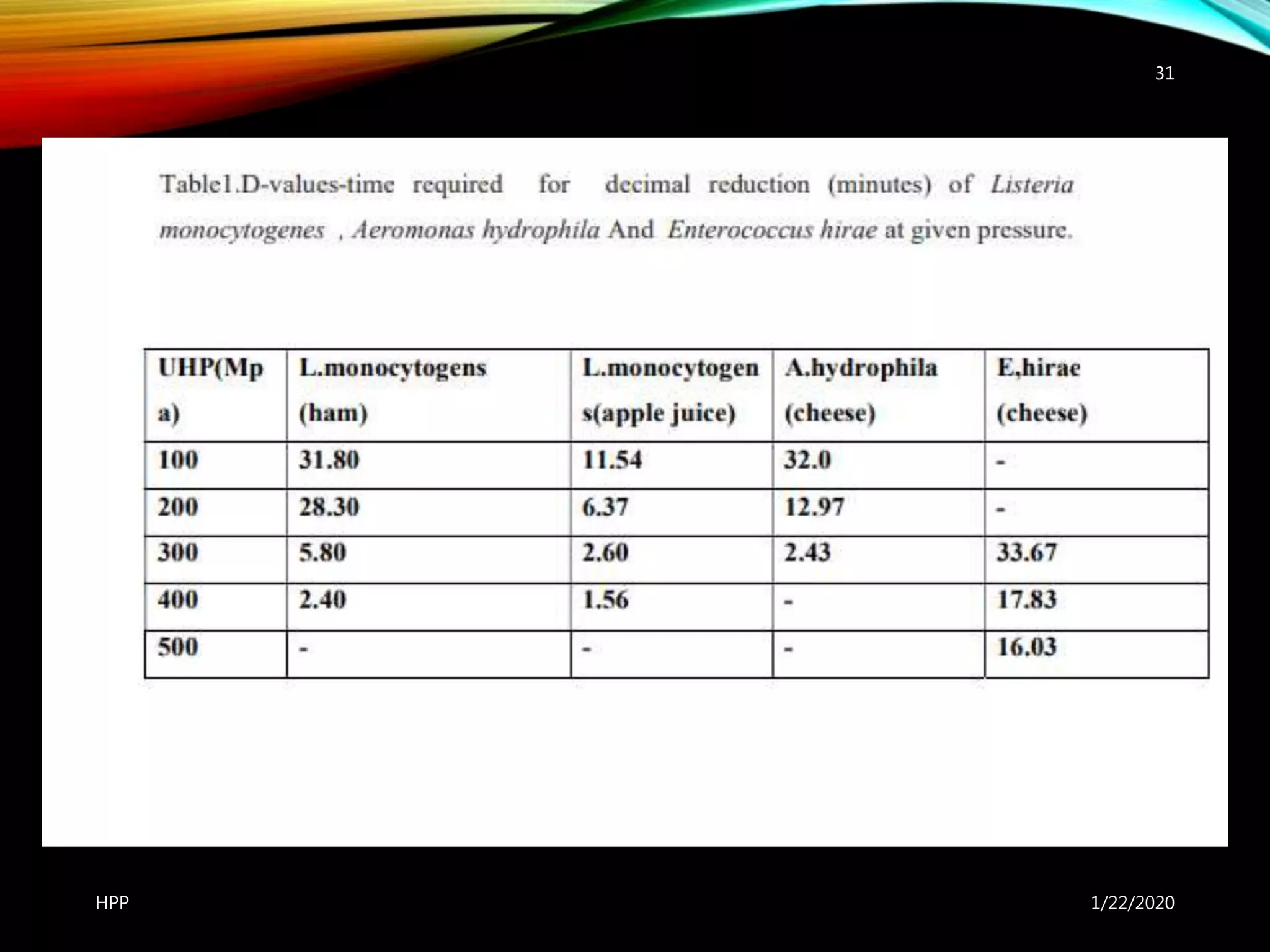

High Pressure Processing (HPP) is a non-thermal food preservation technique that effectively inactivates microorganisms while retaining nutritional and sensory qualities of food. It operates within a pressure range of 100-800 MPa, impacting microbial viability and extending shelf life across various food industries like fruits, meat, and dairy. Despite its advantages, HPP requires significant investment and complex machinery, posing limitations for commercial scalability.