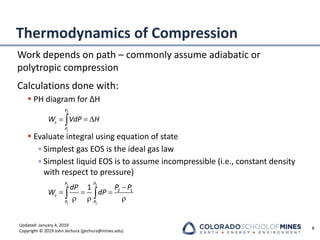

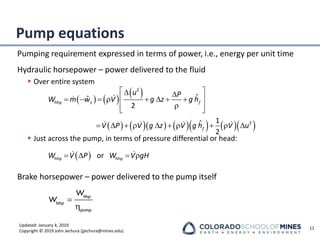

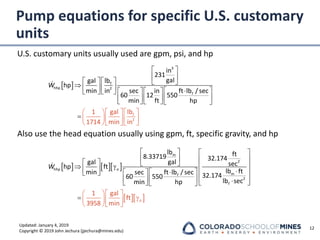

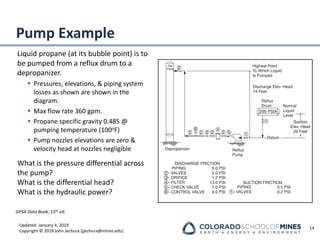

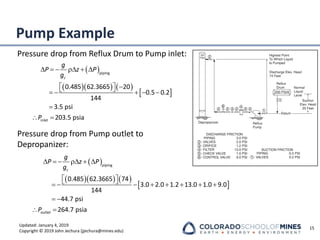

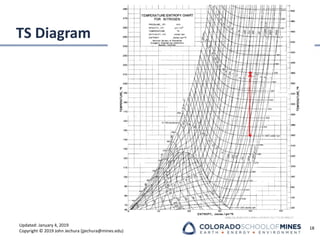

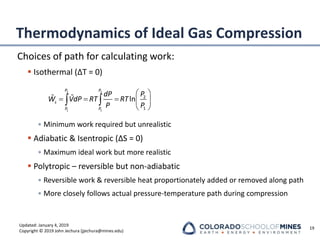

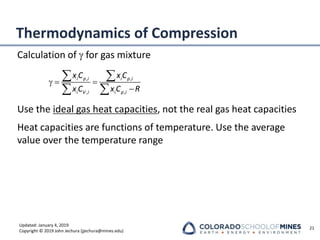

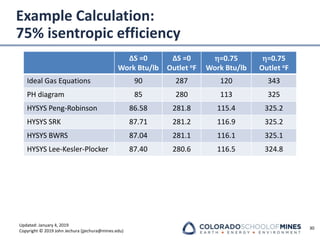

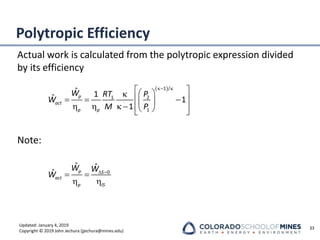

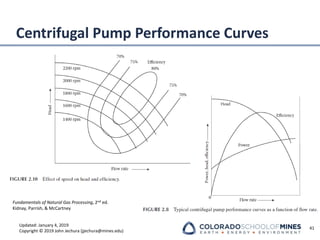

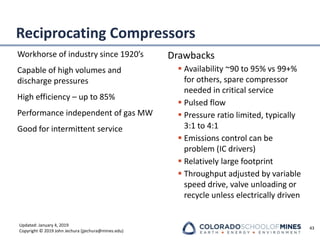

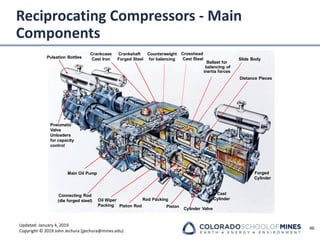

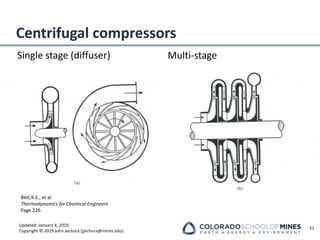

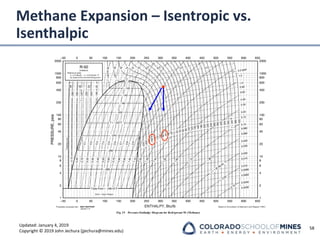

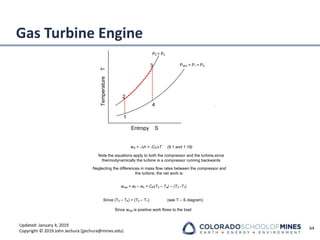

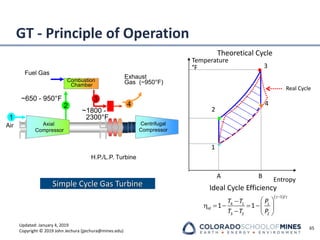

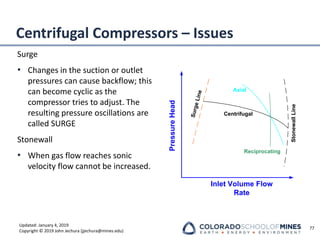

This document provides an overview of rotating equipment including pumps, compressors, turbines, and expanders. It covers fundamentals of thermodynamics including the first and second laws of thermodynamics. Key concepts discussed include starting relationships, Bernoulli's equation, use of PH and TS diagrams, and efficiencies. Specific equipment types are also outlined including centrifugal and reciprocating pumps and compressors, screw compressors, and gas turbines. Common units used in the industry are also defined. Work calculations for pumping and gas compression are demonstrated using isentropic relationships.