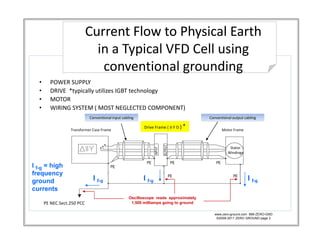

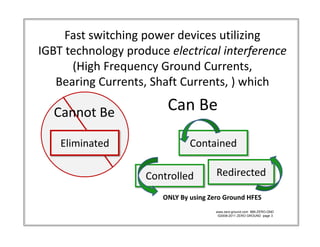

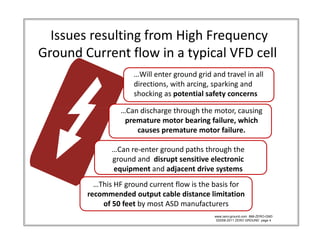

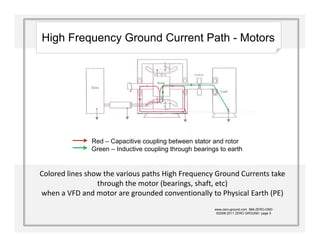

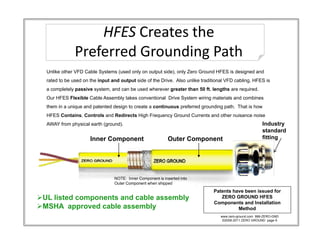

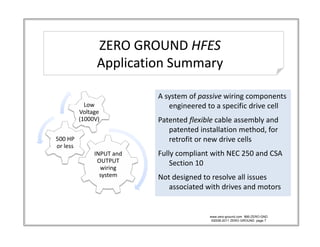

Grounding is the most misunderstood aspect of electrical distribution. Conventional grounding methods for variable frequency drives (VFDs) are insufficient and can cause issues. High frequency ground currents produced by VFDs using IGBT technology can travel through ground grids, cause motor and electronic equipment damage, and disrupt nearby systems if not properly contained. Zero Ground's HFES system is a passive grounding solution that creates a continuous low impedance path to safely contain these ground currents and prevent issues, requiring no maintenance over the long-term.