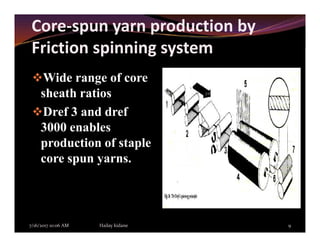

The document discusses core spun yarns. Core spun yarns consist of a central core made of filament, elastane or staple fibers wrapped by a sheath of staple fibers. They can be produced using various spinning methods like ring spinning, rotor spinning, air jet spinning or friction spinning. Core spun yarns have applications as sewing threads and stretch fabrics due to properties derived from the core material. Production parameters like heater temperature and stretch ratio impact properties of core spun yarns like shrinkage and tenacity. Bulked acrylic yarns use a blend of relaxed and unrelaxed fibers to create bulk through fiber shrinkage upon heating after spinning.