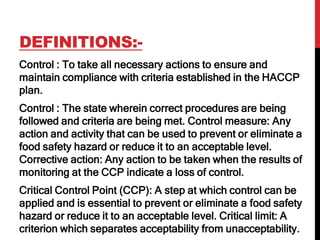

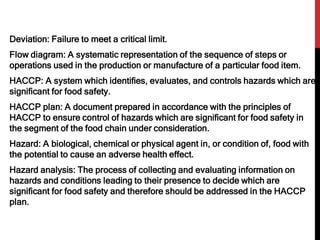

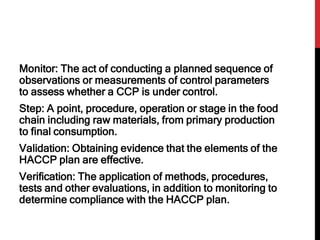

This document defines key terms related to Hazard Analysis and Critical Control Points (HACCP) and outlines the seven principles of a HACCP system. It describes conducting a hazard analysis to identify food safety hazards, determining critical control points to control hazards, establishing critical limits for control points, monitoring procedures, corrective actions for deviations, recordkeeping, and verification activities to ensure the HACCP system is functioning properly. The seven principles are: conduct hazard analysis, determine critical control points, establish critical limits, establish monitoring procedures, establish corrective actions, establish recordkeeping, and establish verification procedures.