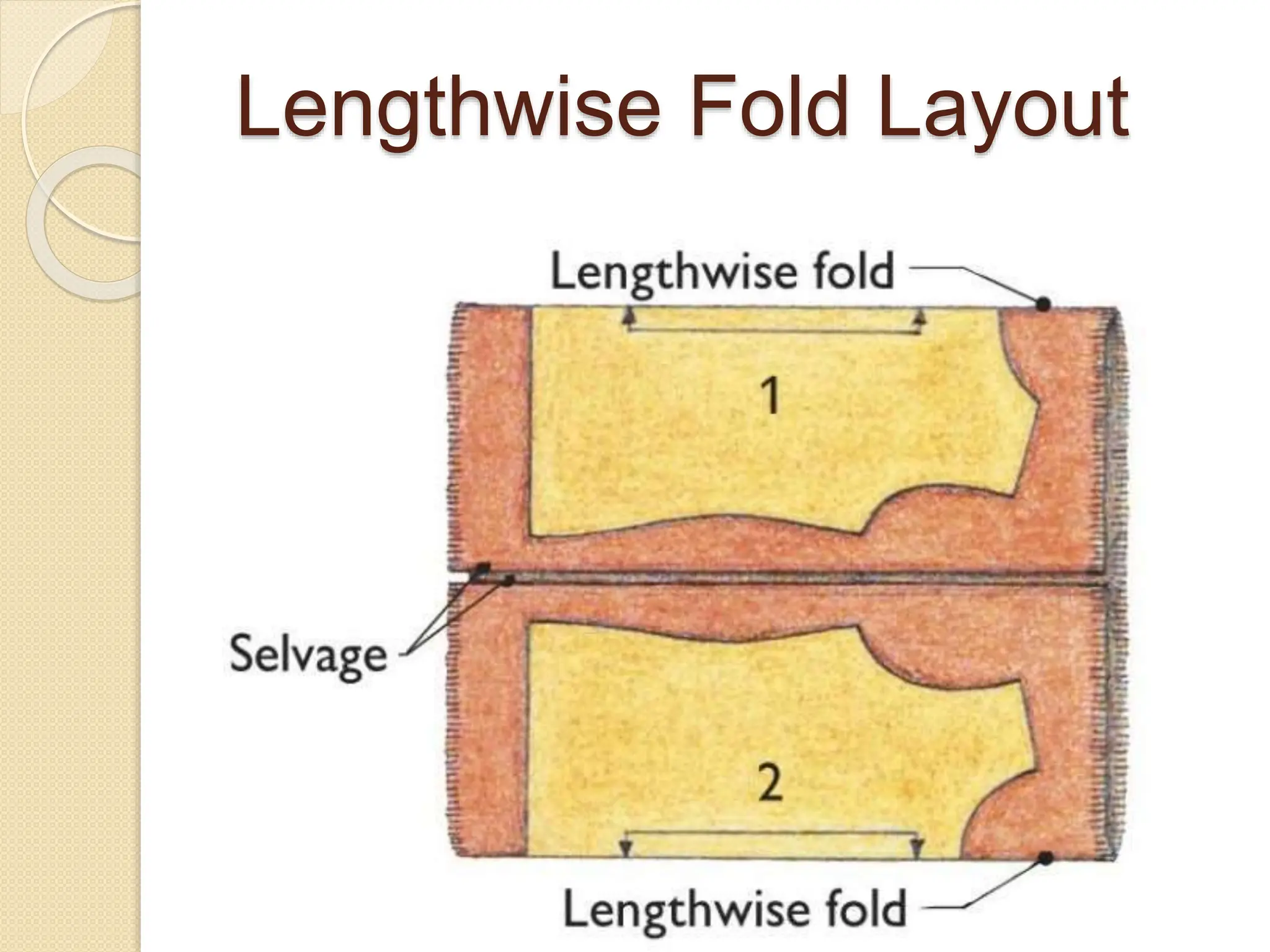

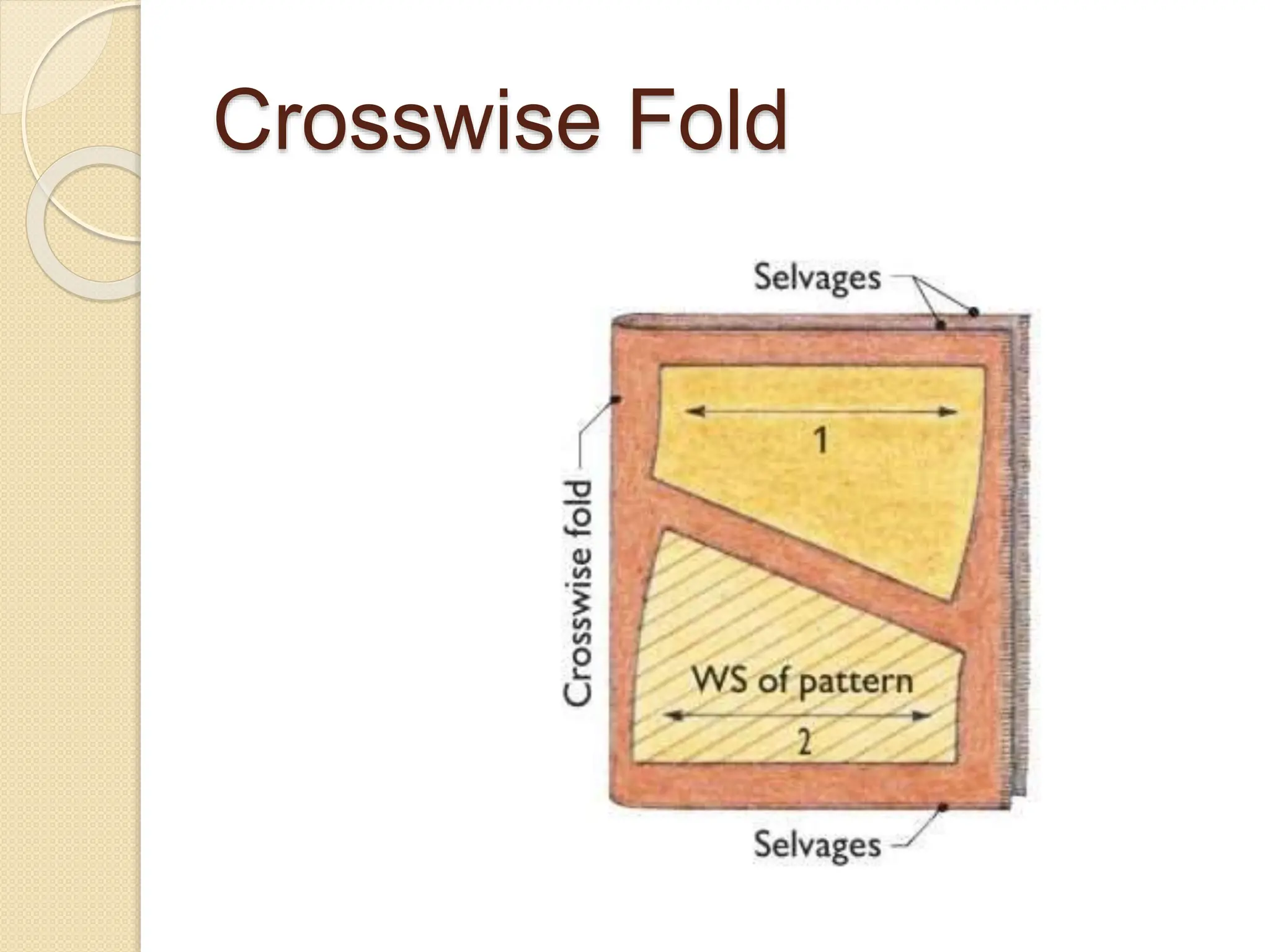

A guidesheet contains all processes for garment construction in a booklet. It shows the order of work, helps estimate time, and ensures all materials are included. The guidesheet includes front and back views, a pattern layout, construction processes, and materials. The pattern layout estimates fabric needs and prepares for cutting. Fabric is prepared by straightening the grain, preshrinking, identifying faults, and pressing before patterns are laid out and cut according to the guidesheet instructions.