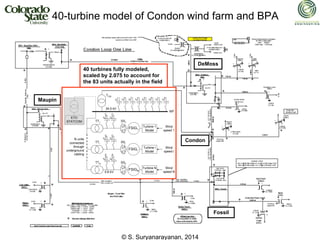

The document analyzes voltage deviation at the Condon wind farm connected to the Bonneville Power Administration network, highlighting persistent deviations of over 9%. It proposes the installation of a static synchronous compensator (STATCOM) as a remedy, validated through high-fidelity modeling and simulation. Various operational characteristics of wind turbines and their impact on voltage management are also discussed, along with recommendations for effective capacitor switching to maintain system stability.

![© S. Suryanarayanan, 2014

Voltage deviation on PCC at Condon

• Persistent voltage deviation of >9% seen regularly

• Note: x-axis is time (1 year period)

01/01/04 03/01/04 04/30/04 06/29/04 08/28/04 10/27/04 12/26/04

90

95

100

105

110

5 min Condon Wind SCADA Data for 365 days starting 01-Jan-2004

Voltage at Wind Farm [%]

Date [MM/DD/YY]

BPA’s nominal operating

voltage level

BPA’s nominal operating

voltage range

• Yet, voltage deviation on PCC was observed periodically](https://image.slidesharecdn.com/wecswithgrid-240711093443-5a27c893/85/GRID-integration-of-Wind-energy-conversion-system-7-320.jpg)

![© S. Suryanarayanan, 2014

-10 0 10 20 30 40 50

0.95

0.96

0.97

0.98

0.99

1

1.01

1.02

1.03

1.04

1.05

1.06

1.07

1.08

Real power delivered by wind farm [MW]

Voltage at the

wind farm [pu]

2s SCADA 03/05/2006

5min SCADA 08/22/2004 - 08/24/2004

Δv = 9%

caused

only in

some

cases

Site established as candidate for testing and installing new

technology for mitigating V deviation

Voltage deviation on PCC at Condon](https://image.slidesharecdn.com/wecswithgrid-240711093443-5a27c893/85/GRID-integration-of-Wind-energy-conversion-system-8-320.jpg)

![© S. Suryanarayanan, 2014

0 5 10 15 20 25 30 35 40 45 50

0.88

0.9

0.92

0.94

0.96

0.98

1

1.02

1.04

1.06

Voltage

at

Condon

Wind

[pu]

Real Power Condon Wind [MW]

2 s SCADA Data

5 min SCADA Data for 3 days starting 22-Aug-2004

No Capacitors (RTDS)

Fossil Capacitors (RTDS)

CWF Capacitors (RTDS)

Power ramped by (slowly) increasing

wind speed uniformly

Validation of hybrid RTDS model

against SCADA Data

More evidence

that

malfunctioning

of Condon

Wind Farm

capacitor

switching

causes the

problem](https://image.slidesharecdn.com/wecswithgrid-240711093443-5a27c893/85/GRID-integration-of-Wind-energy-conversion-system-22-320.jpg)

![© S. Suryanarayanan, 2014

BPA Recent Data

Proper cap bank switching

Condon Wind Farm Voltage

[kV]

time [s]

10 min

When cap switching control at Condon Wind works properly, the voltage stays within BPA

criteria as FSU studies predicted

- As confirmed by BPA via email on 11/22/2006](https://image.slidesharecdn.com/wecswithgrid-240711093443-5a27c893/85/GRID-integration-of-Wind-energy-conversion-system-23-320.jpg)