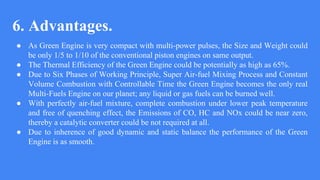

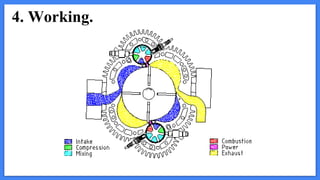

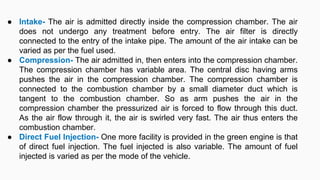

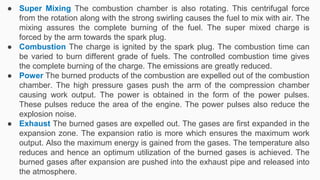

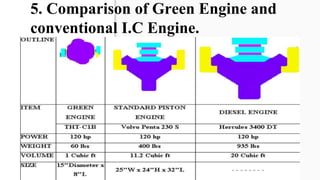

The document provides a comprehensive overview of the six-phase green engine, detailing its unique features, construction, working phases, and significant advantages over conventional internal combustion engines. It is described as a compact, highly efficient, and versatile engine capable of using various liquid and gaseous fuels while producing near-zero emissions. The potential applications for this innovative engine span across transportation, military, and other industries, highlighting its future scope and environmental benefits.

![6. Advantages.

Small size

For same

output.

Near zero

CO,HC

and NOx.

[65+]%

thermal

efficiency.

Smooth

engine

performa-

nce. +

Only real

multi-

fuels

engine.

Overall

cost is

lower.](https://image.slidesharecdn.com/six-phasegreenengine-201004130602/85/Six-phase-green-engine-15-320.jpg)