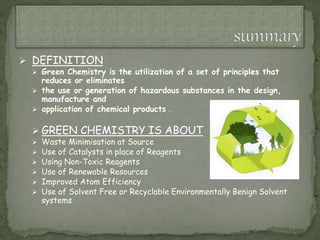

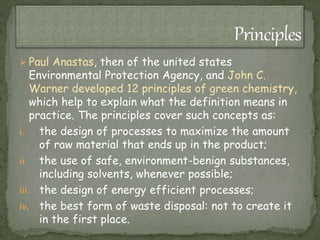

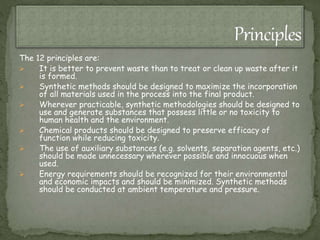

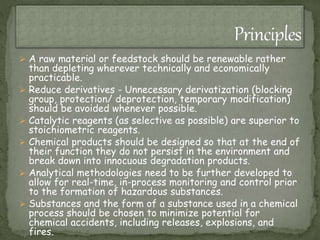

Green chemistry seeks to minimize pollution and hazardous waste by designing chemical products and processes. It encourages safer product design, renewable feedstocks, and prevention of waste over treatment. The 12 principles of green chemistry provide a framework for minimizing risk through safer chemicals, renewable resources, energy efficiency, and design for degradation. Examples show how green chemistry has helped reduce pollution from dry cleaning, lead, and firefighting foams.

![Making chemical products that do not

harm either our health or the

environment,[harmless chemicals]

Using industrial processes that reduce

or eliminate hazardous chemicals, and

Designing more efficient processes that

minimize the production of waste

materials.](https://image.slidesharecdn.com/greenchemistry-170829121902/85/Green-chemistry-19-320.jpg)