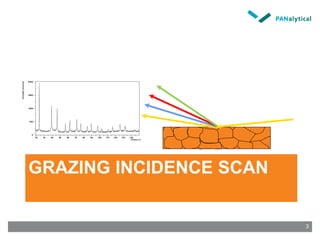

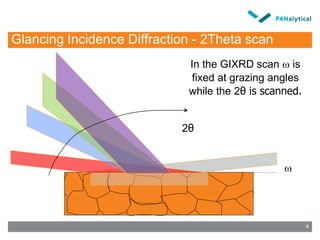

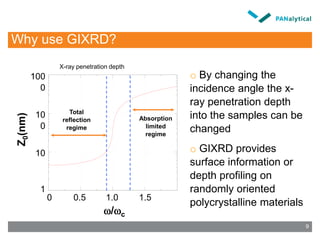

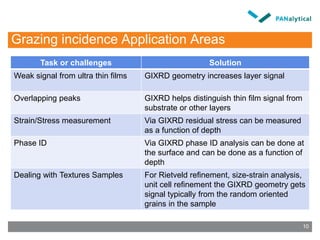

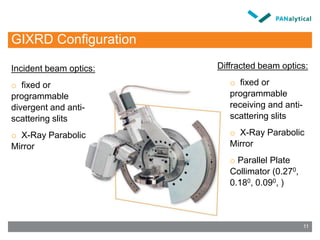

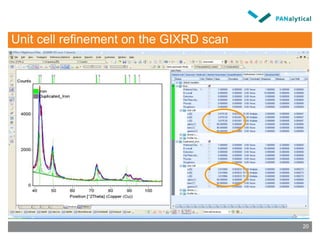

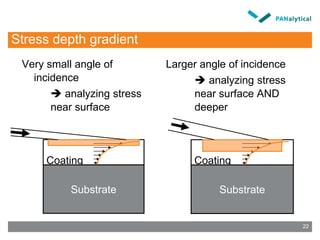

- Grazing incidence X-ray diffraction (GIXRD) is a technique that allows analyzing thin film samples by varying the incident angle of the X-rays to change their penetration depth.

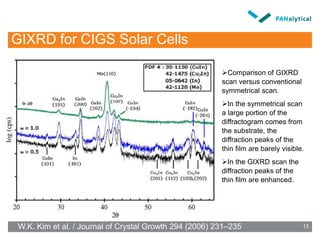

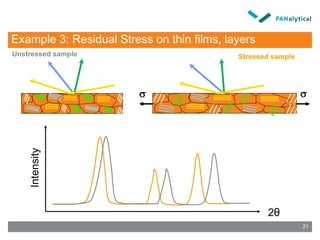

- GIXRD provides enhanced signals from thin film layers compared to conventional XRD and helps distinguish thin film peaks from substrate peaks. It can also be used to analyze phases, stress, and crystal structure as a function of depth.

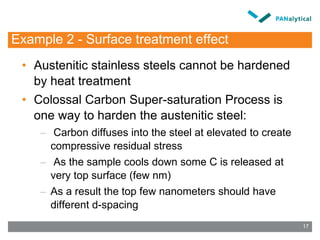

- Examples showed how GIXRD allowed analyzing phase composition and residual stress at different depths in thin film solar cell structures and revealed surface treatment effects in a stainless steel sample.

![GIXRD - Thin film depth profiling phase analysis

Position [°2Theta] (Copper (Cu))

10 20 30 40 50 60 70

Counts

0

400

1600

0

400

1600

0

400

1600

3600

, Incident angle

0.45 deg

1.00 deg

2.00 deg

CIGS

Mo

ZnO

ZnO

CIGS

ZnO

Mo

ZnO

CIGS

ZnO

Mo

Position [°2Theta] (Copper (Cu))

10 20 30 40 50 60

0

0

0

0

0

14](https://image.slidesharecdn.com/gixrd-12881577445025-phpapp02/85/Gixrd-14-320.jpg)

![GIXRD - Thin film depth profiling phase analysis

Position [°2Theta] (Copper (Cu))

10 20 30 40 50 60 70

Counts

0

400

1600

0

400

1600

0

400

1600

3600

, Incident angle

0.45 deg

1.00 deg

2.00 deg

CIGS

Mo

ZnO

ZnO

CIGS

ZnO

Mo

ZnO

CIGS

ZnO

Mo

Position [°2Theta] (Copper (Cu))

10 20 30 40 50 60

0

0

0

0

0

0

0

15](https://image.slidesharecdn.com/gixrd-12881577445025-phpapp02/85/Gixrd-15-320.jpg)

![GIXRD - Thin film depth profiling phase analysis

Position [°2Theta] (Copper (Cu))

10 20 30 40 50 60 70

Counts

0

400

1600

0

400

1600

0

400

1600

3600

, Incident angle

0.45 deg

1.00 deg

2.00 deg

CIGS

Mo

ZnO=0.45

ZnO

CIGS

ZnO

Mo

=1

ZnO

CIGS

ZnO

Mo

=2

16](https://image.slidesharecdn.com/gixrd-12881577445025-phpapp02/85/Gixrd-16-320.jpg)

![Depth profiling GIXRD-Austenitic stainless steel

Position [°2Theta] (Copper (Cu))

40 50 60 70 80 90 100

Counts

0

1000

0

2000

4000

0

500

1000

0

1000

0

2000

Incidence angle

0.5 0

0.8 0

1.0 0

2.0 0

0.3 0

18](https://image.slidesharecdn.com/gixrd-12881577445025-phpapp02/85/Gixrd-18-320.jpg)

![GIXRD - Austenitic stainless steel – Zoom in

Position [°2Theta] (Copper (Cu))

40 45 50 55

Counts

0

1000

0

2000

4000

0

500

1000

0

1000

0

2000

Incidence angle

0.5 0

0.8 0

1.0 0

2.0 0

0.3 0

19](https://image.slidesharecdn.com/gixrd-12881577445025-phpapp02/85/Gixrd-19-320.jpg)

![Stress with depth in CdTe layer of solar cell

0 2 4 6 8 10 12

-120

-100

-80

-60

-40

-20

ResidualStress[MPa]

Grazing Angle [degrees]

20 30 40 50 60 70 80 90 100 110 120 130 140

2Theta (°)

0

100

400

900

1600

2500

3600

Intensity(counts)

20 30 40 50 60 70 80 90 100 110 120 130 140

2Theta (°)

0

400

1600

3600

6400

Intensity(counts)

20 30 40 50 60 70 80 90 100 110 120 130 140

2Theta (°)

0

400

1600

3600

6400

Intensity(counts)

=0.1

=1

=5

23](https://image.slidesharecdn.com/gixrd-12881577445025-phpapp02/85/Gixrd-23-320.jpg)