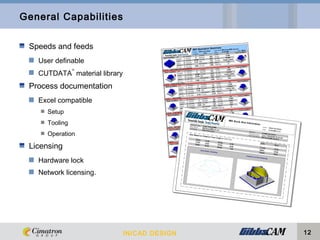

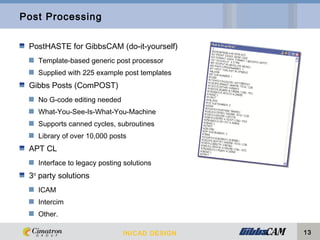

GibbsCAM is a CAM software solution for programming multitasking mill-turn CNC machines. It was founded in 1982 and acquired by Cimatron in 2008. GibbsCAM allows for integrated CAD data processing, machine simulation, and post-processing for multitasking mill-turn machines. It provides capabilities for multi-axis milling, turning, and live tooling operations to maximize productivity on multi-turret and multi-spindle machines.