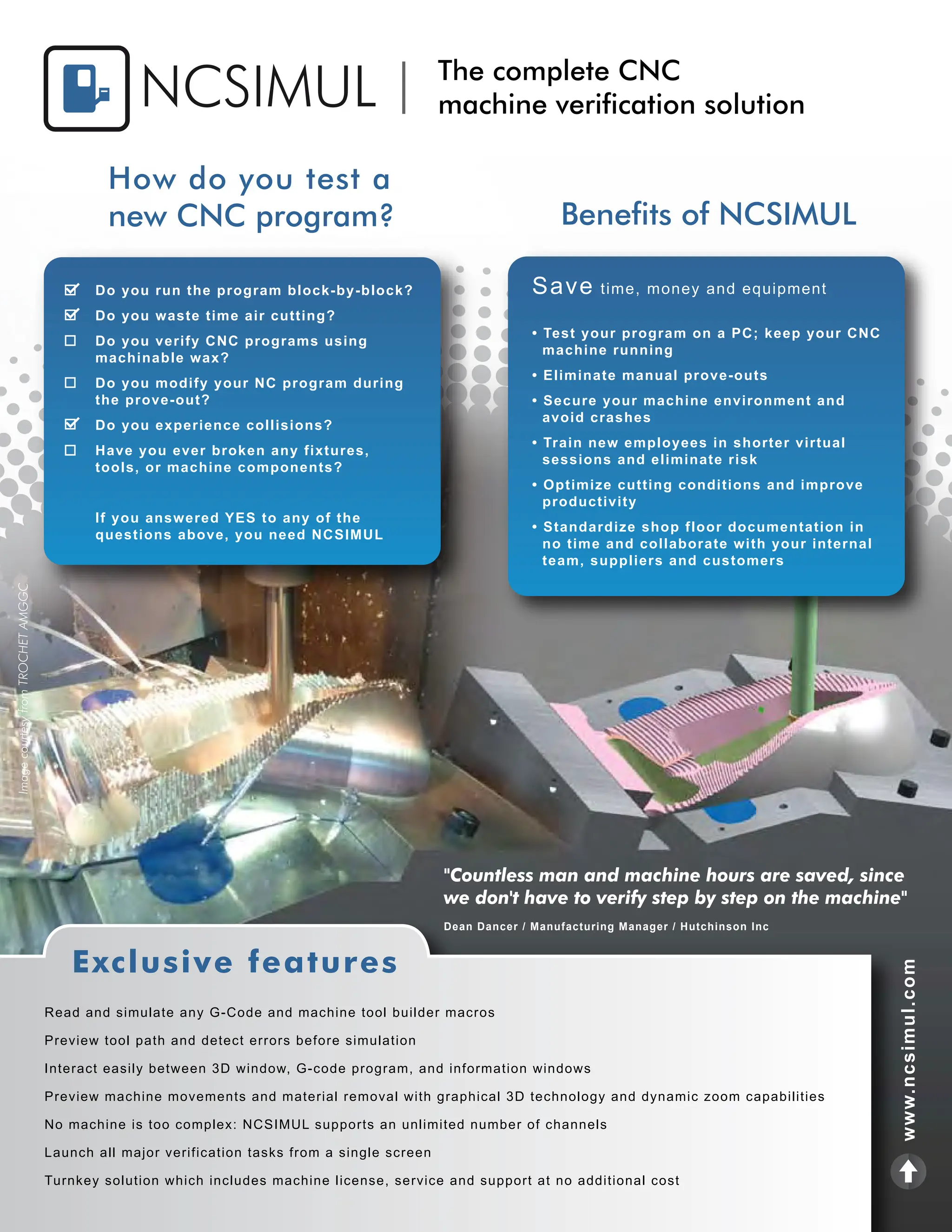

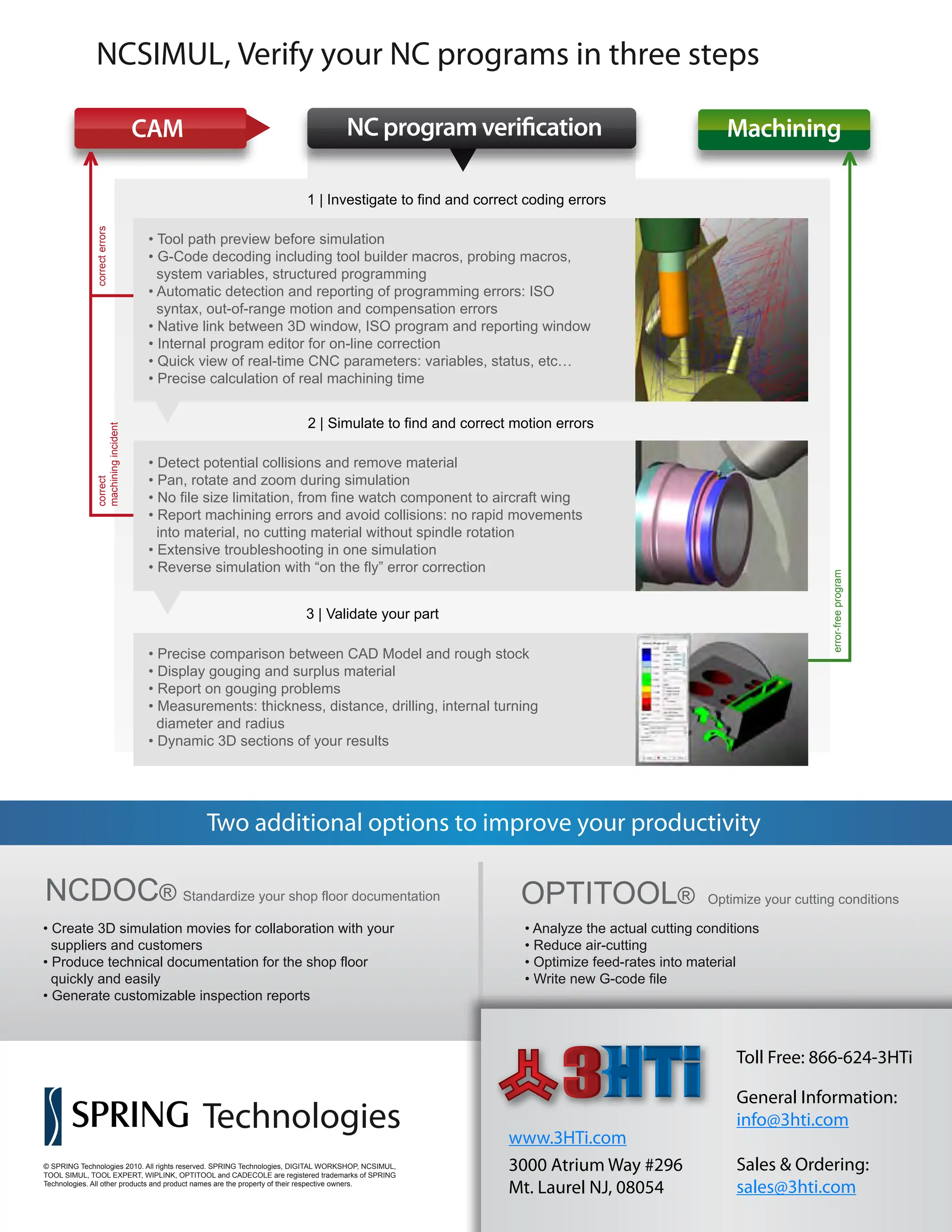

NCSIMUL offers a comprehensive CNC machine verification solution that allows users to read, simulate, and verify G-code along with machine tool macros to detect and correct errors prior to machining. It enhances productivity by enabling testing on a PC, eliminating manual prove-outs, and reducing risks through virtual training sessions. Key features include automatic error detection, real-time parameter viewing, and detailed reporting, which collectively aid in optimizing machining processes and ensuring error-free programs.