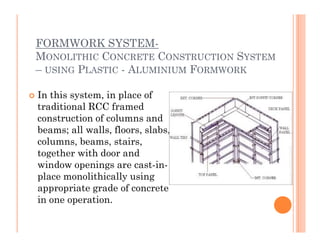

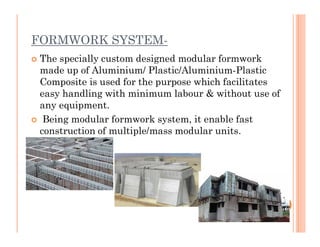

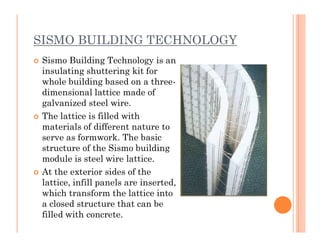

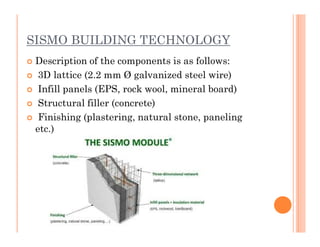

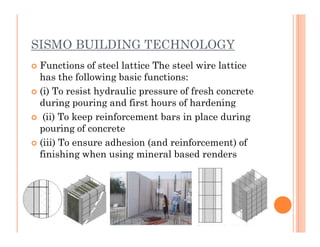

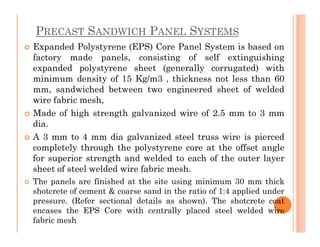

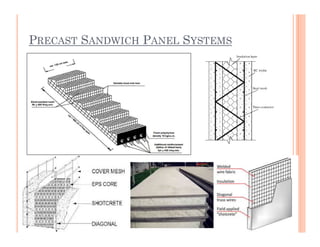

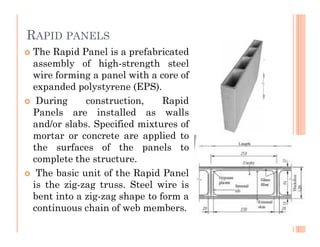

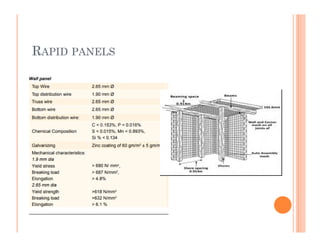

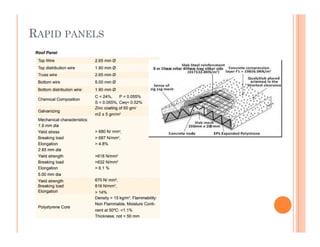

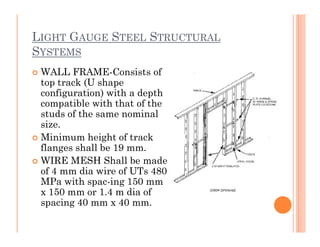

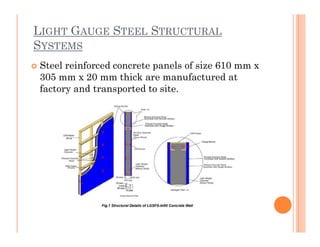

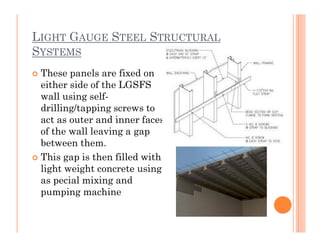

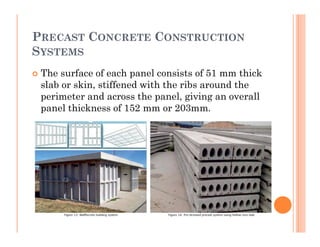

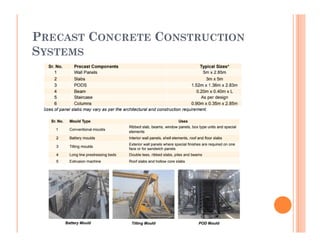

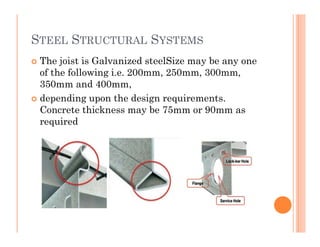

This document discusses emerging construction techniques for mass housing, including precast sandwich panel systems, light gauge steel framing, and precast concrete construction. It describes formwork systems that use plastic or aluminum forms to cast concrete monolithically. Precast sandwich panels sandwich an insulating core between welded wire fabric mesh. Light gauge steel uses cold-formed galvanized steel frames. Precast concrete uses prefabricated hollow columns, beams, slabs and stairs. Formwork, precast panels and light gauge steel allow for rapid, repetitive construction of housing units at scale.