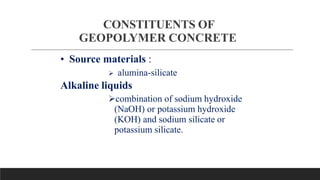

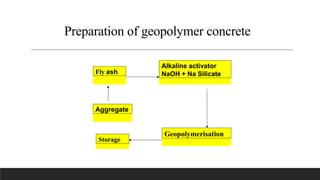

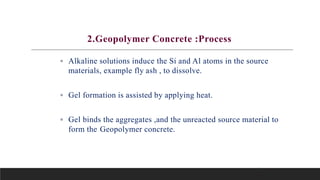

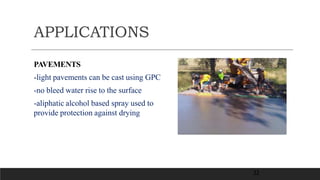

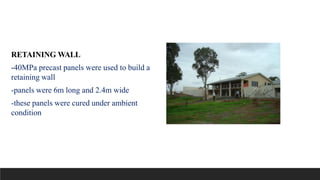

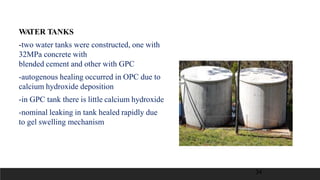

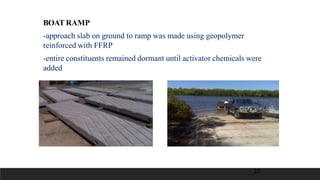

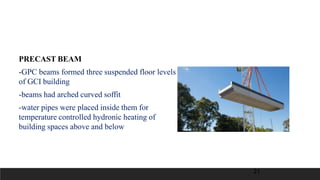

Geopolymer concrete is an alternative to traditional cement concrete that has lower environmental impact. It is made from industrial byproducts like fly ash and an alkaline solution, which allows it to set through a polymerization process rather than hydration. Geopolymer concrete has advantages like lower CO2 emissions, higher strength, and better acid and salt resistance compared to ordinary Portland cement. While it is more difficult to produce and cure than traditional concrete, geopolymer concrete has applications in pavements, retaining walls, water tanks, and precast construction elements.