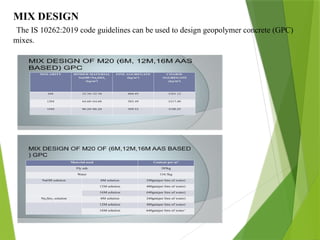

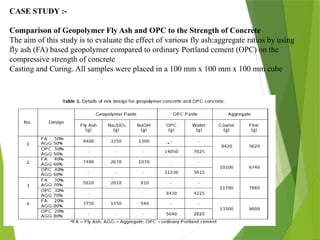

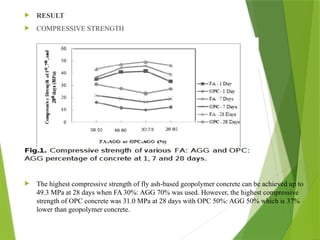

Geopolymer concrete is an innovative, eco-friendly alternative to traditional cement concrete, using industrial waste materials like fly ash and slag as binders, which helps reduce CO2 emissions and conserve natural resources. It demonstrates superior durability, resistance to heat and acids, and benefits from enhanced mechanical properties compared to ordinary Portland cement (OPC). Applications include highway construction, underground structures, and environments exposed to corrosive agents, making geopolymer concrete a sustainable choice for various civil engineering projects.