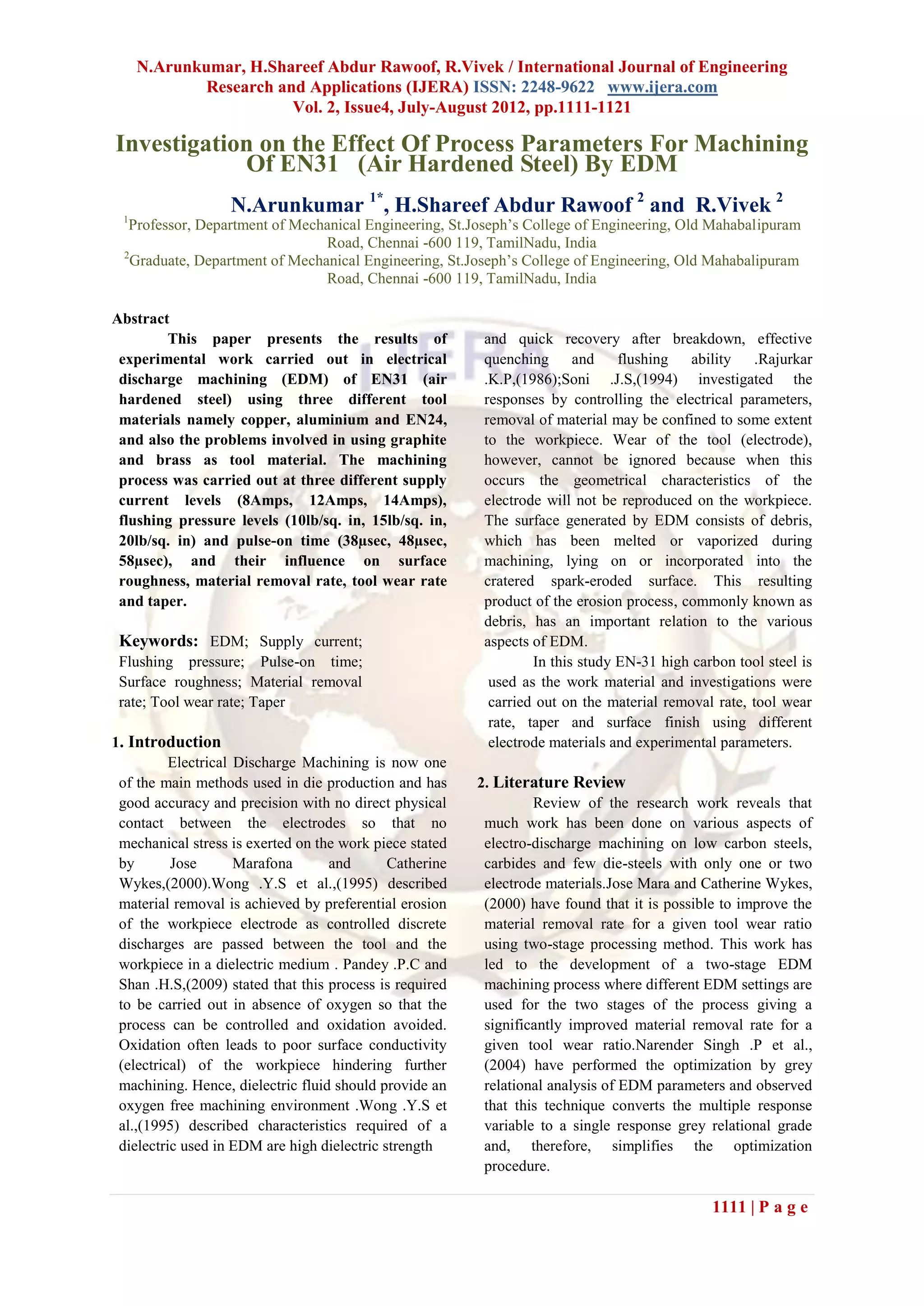

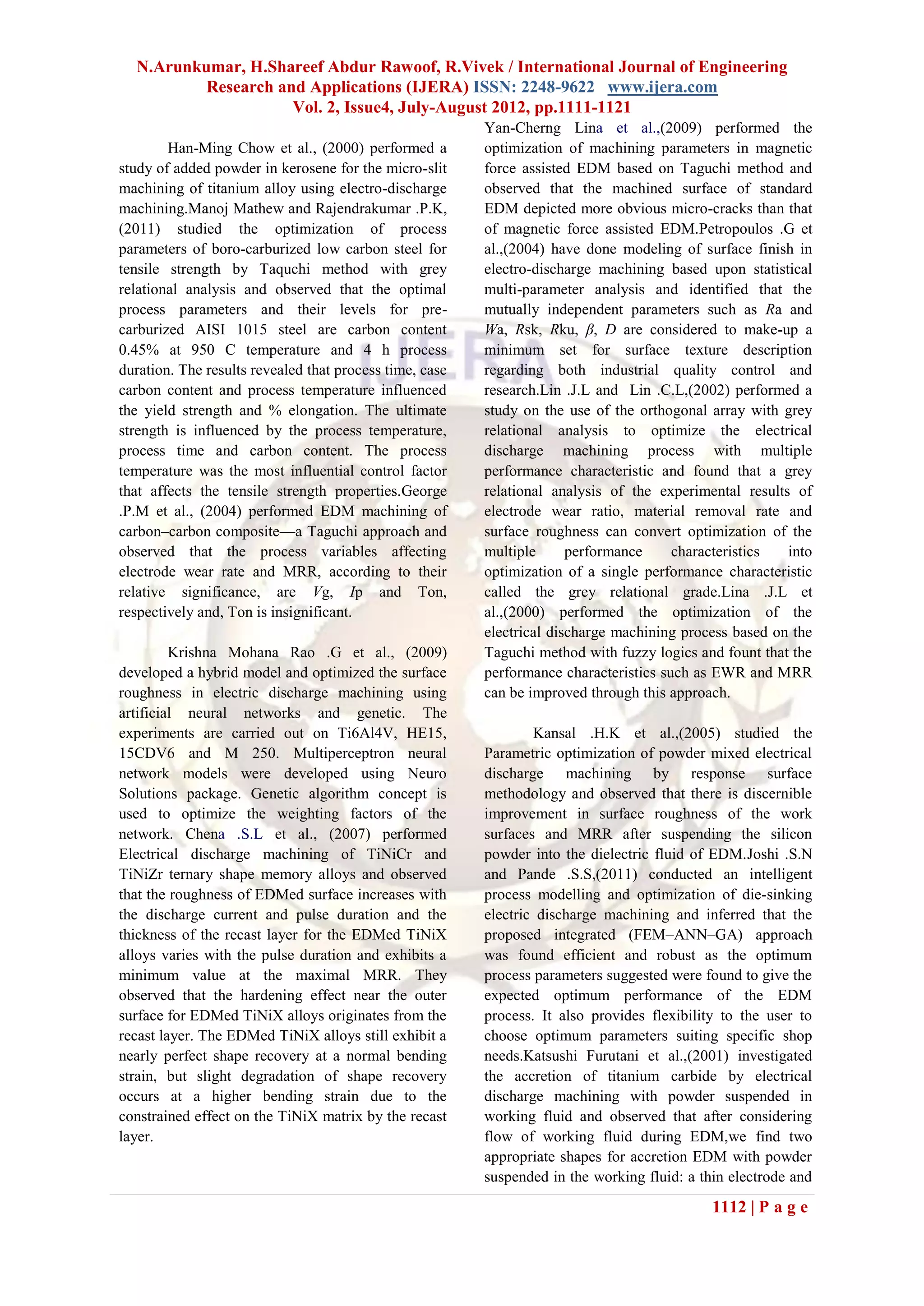

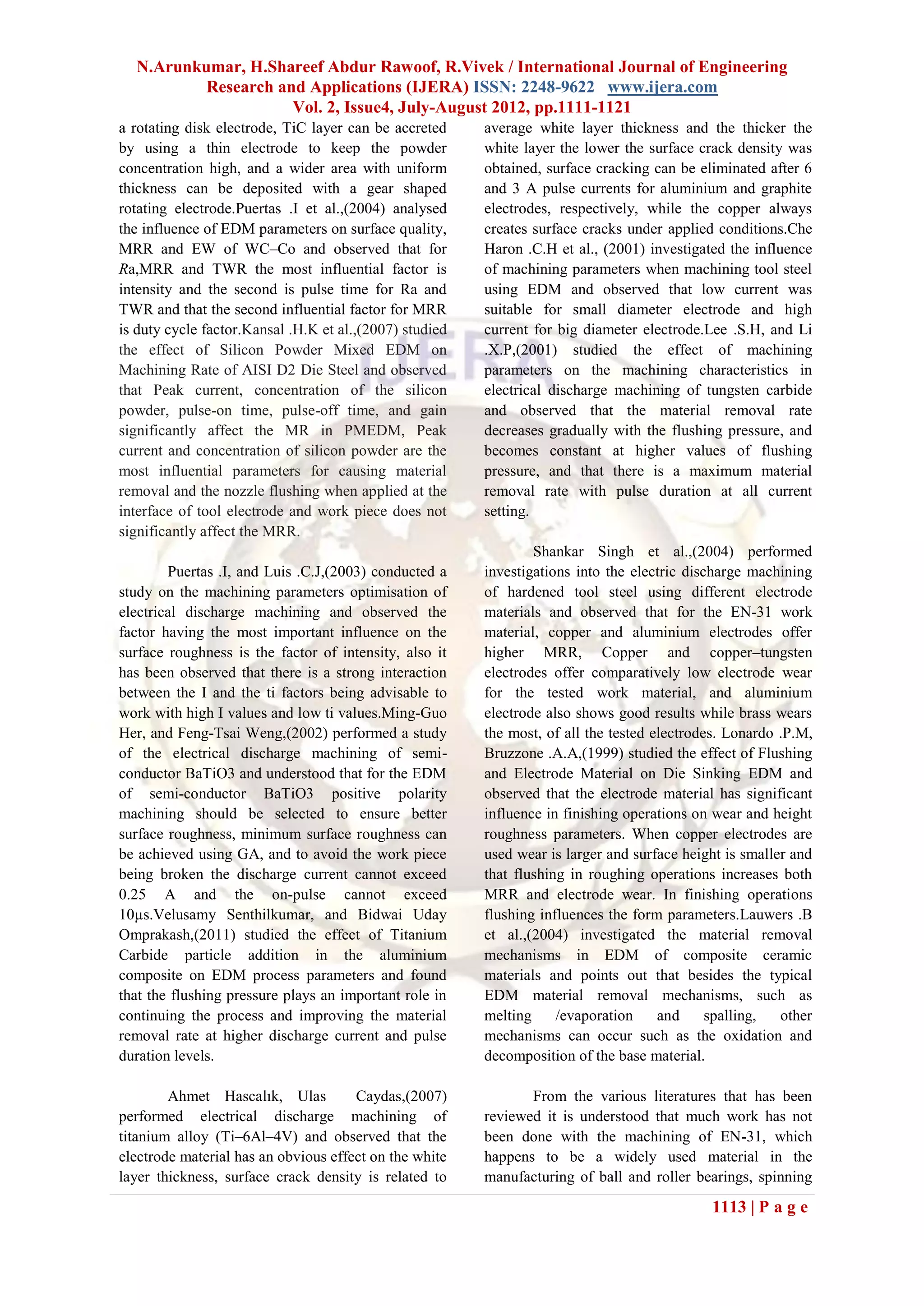

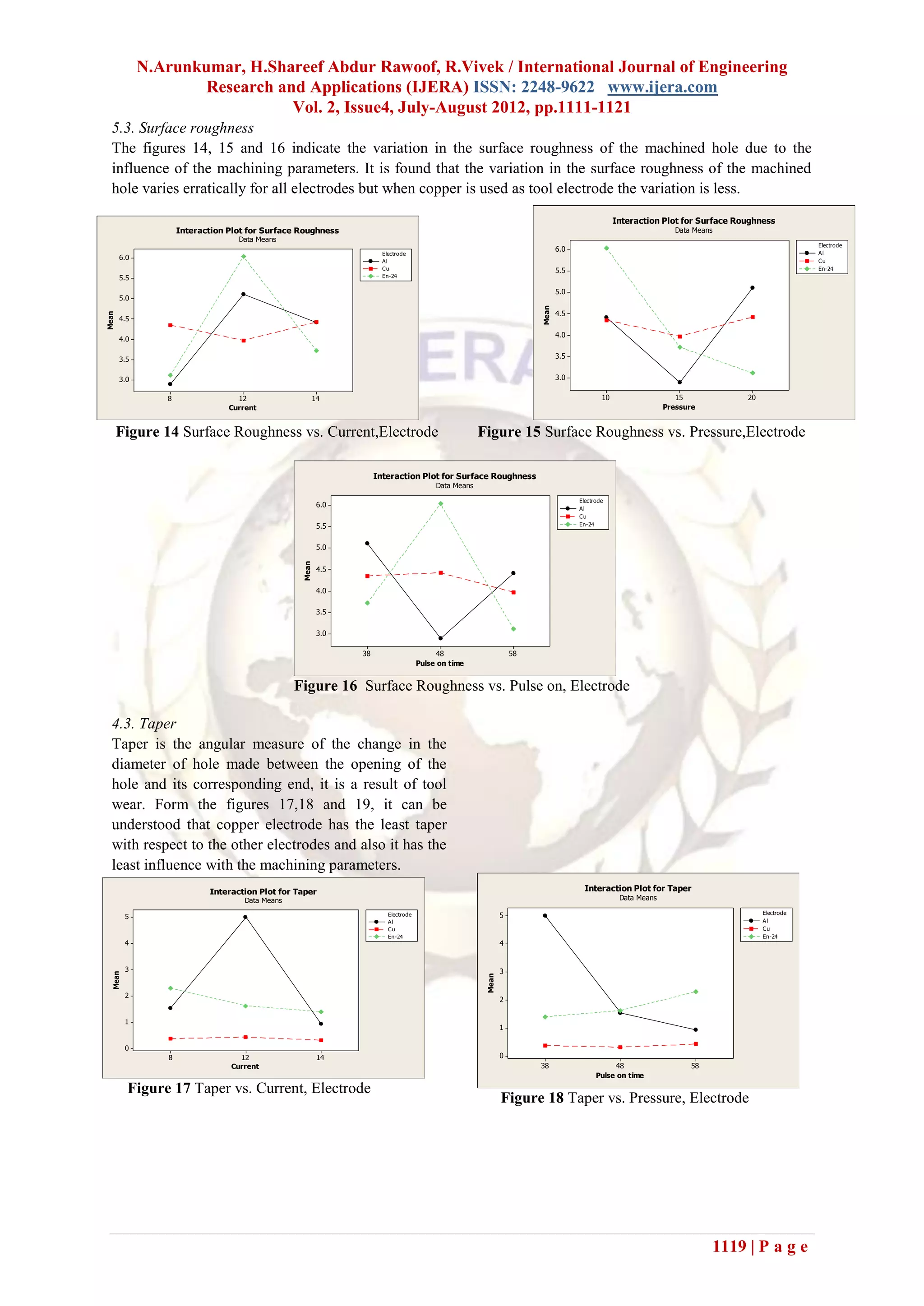

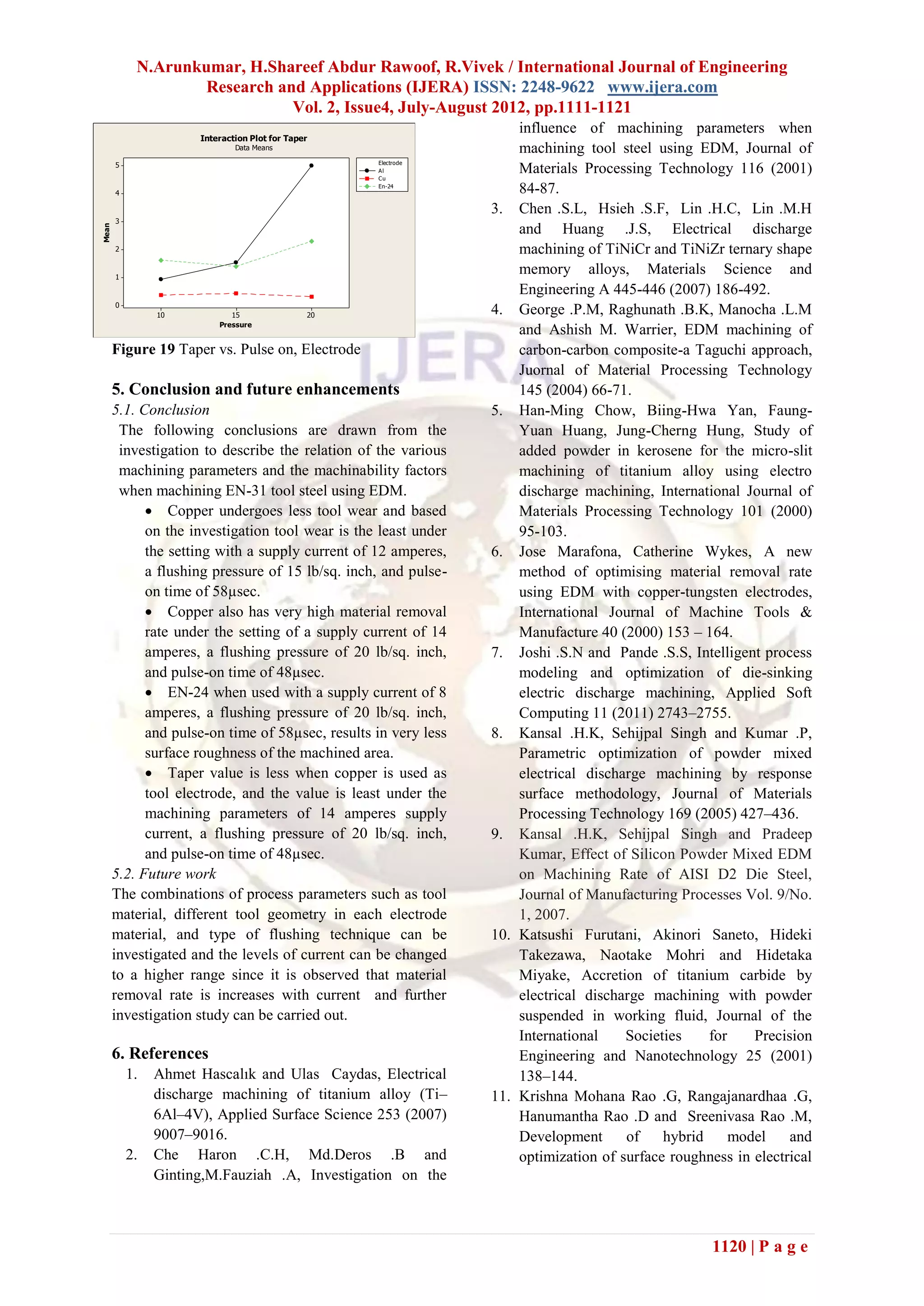

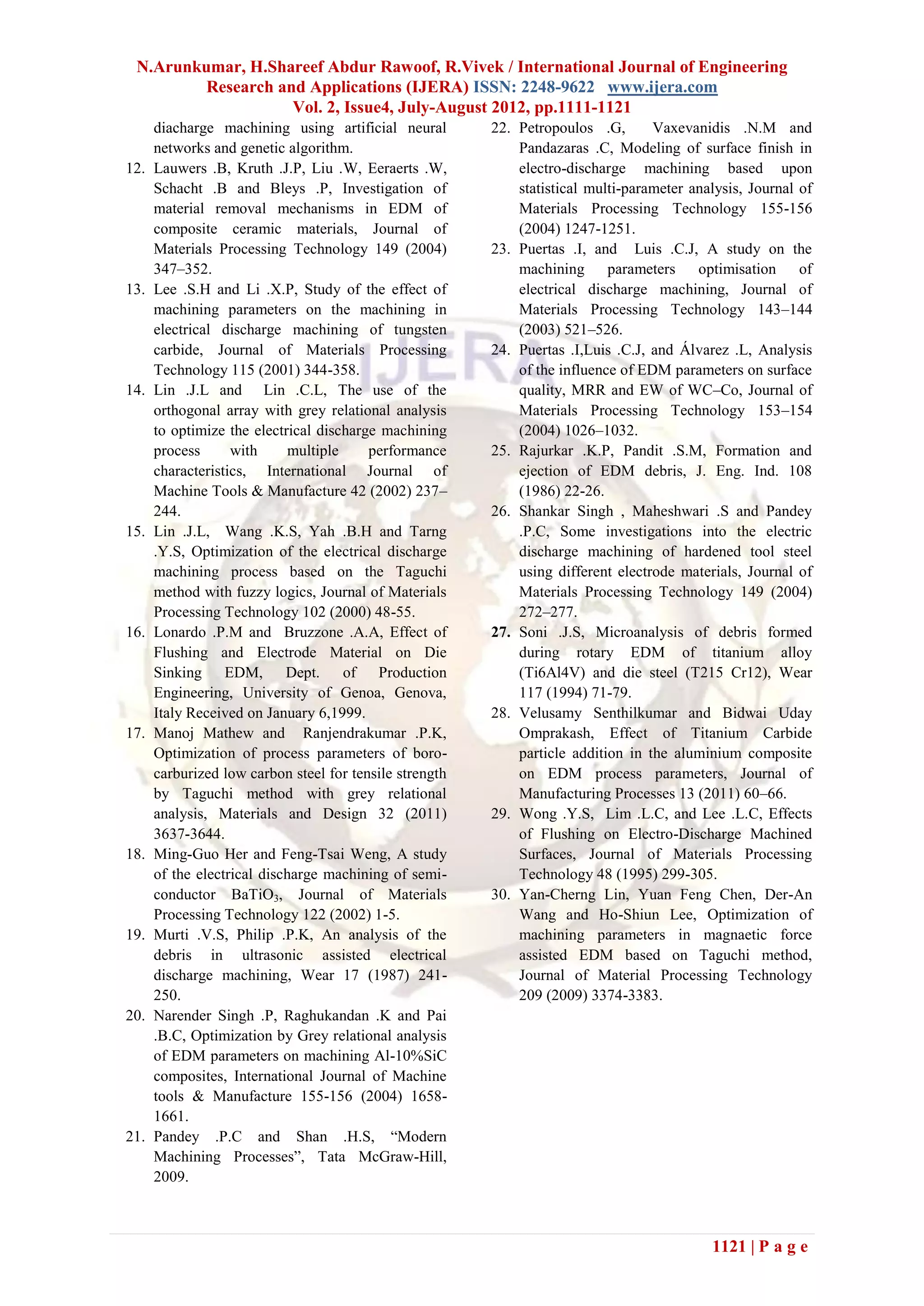

This document summarizes a study that investigated the effect of process parameters on machining EN31 steel using electrical discharge machining (EDM). Experiments were conducted using different tool materials (copper, aluminum, and EN24), supply currents, flushing pressures, and pulse-on times. The experiments analyzed their influence on surface roughness, material removal rate, tool wear rate, and taper. The results of this study can help optimize the EDM process for machining EN31 steel.