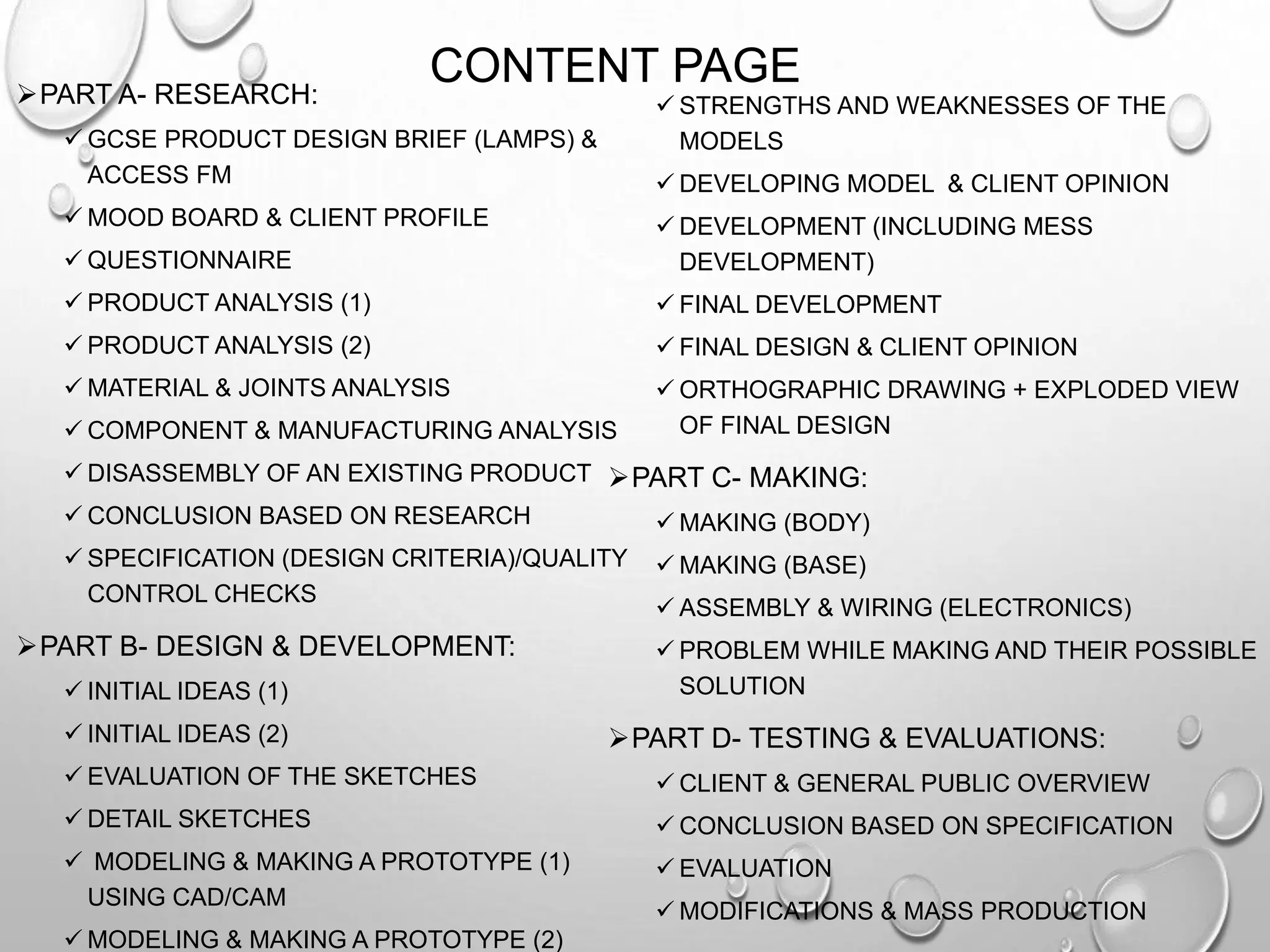

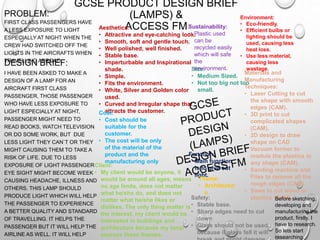

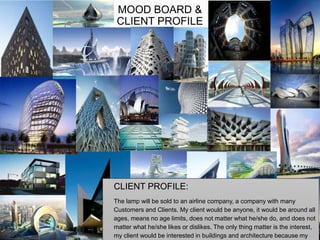

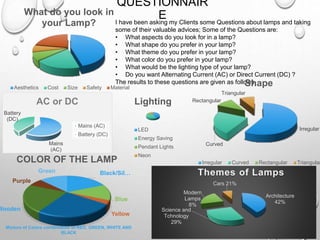

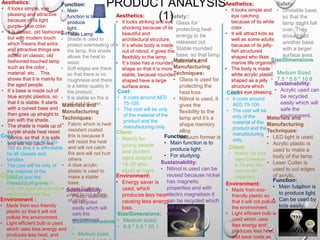

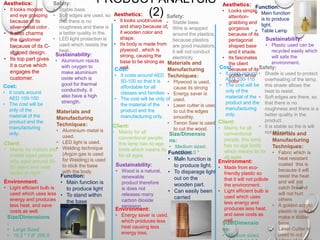

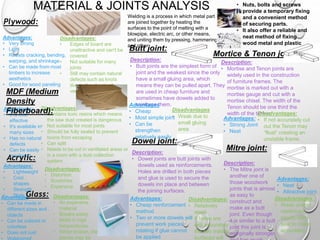

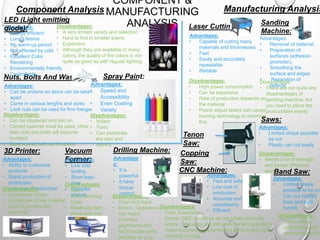

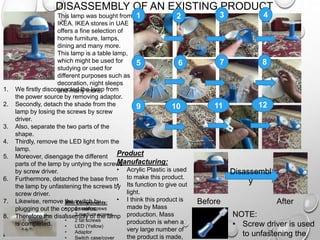

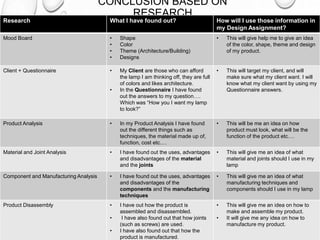

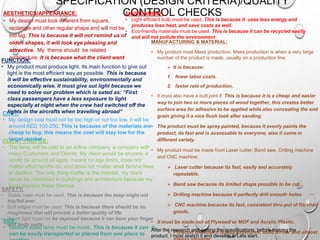

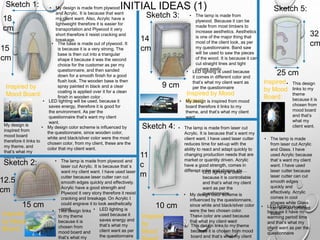

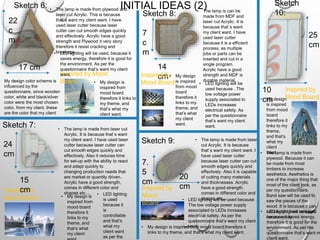

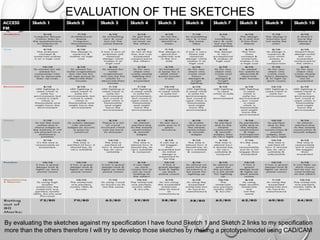

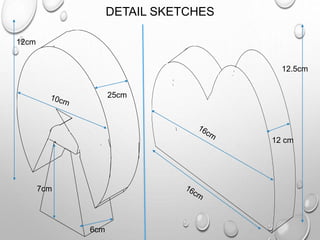

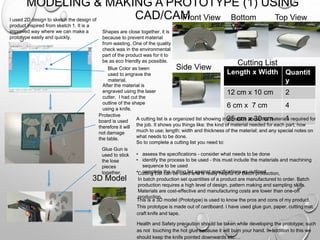

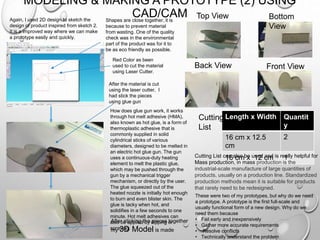

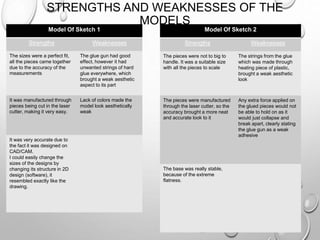

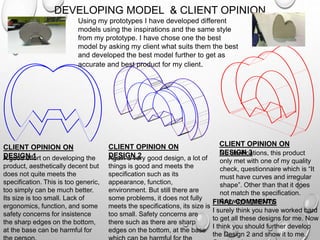

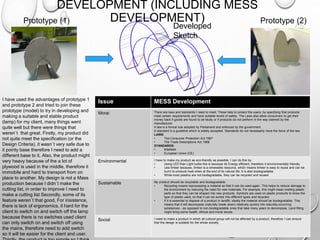

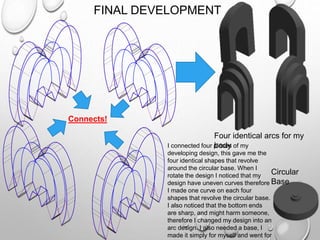

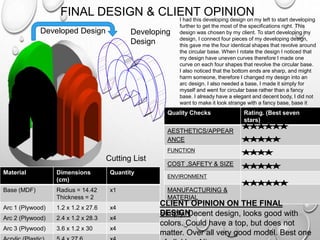

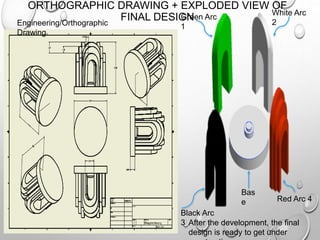

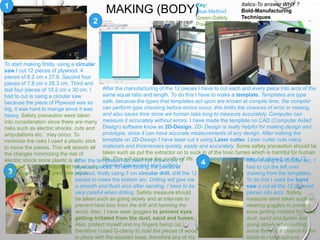

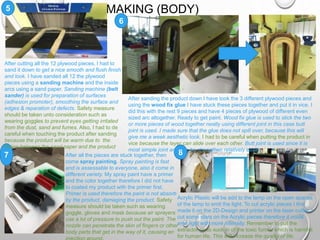

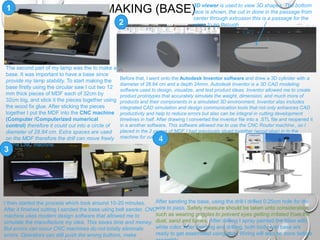

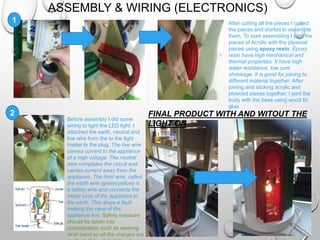

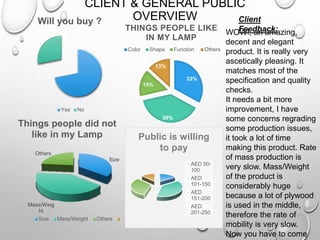

The document outlines the content sections of a GCSE product design project on lamps for aircraft passengers. It includes sections for research, design and development, manufacturing, and testing. The research section includes a product brief, mood board, client profile, questionnaires, product analyses, material analyses, and specifications. The design section includes sketching initial ideas, developing detailed sketches, prototyping models, evaluating designs, and creating final designs. The manufacturing section covers creating components and assembling the final product. The testing section involves client and user evaluations and assessing the final product against the original specifications.