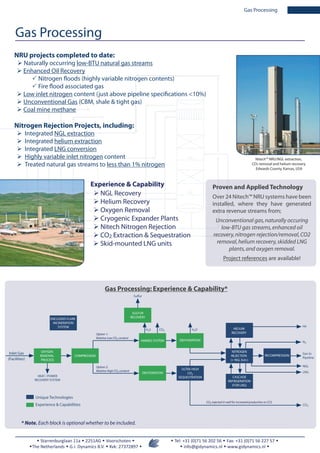

The document discusses Nitech nitrogen rejection unit (NRU) technology for processing natural gas. It notes that the NRU uses cryogenic processing to economically remove nitrogen from gas streams without the complexity of traditional cryogenic methods. The NRU typically only includes an inlet compressor, heat exchanger, and cryogenic box, providing a small footprint and lower costs than other options. Over 24 NRU systems have been installed to process low-BTU gas, enhance oil recovery, and remove nitrogen, carbon dioxide, helium, and oxygen from treated gas streams. The document promotes the NRU technology and experience of the company for various gas processing applications.