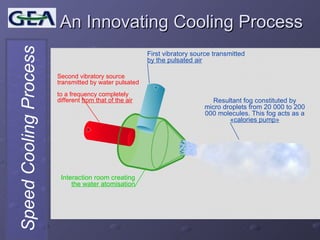

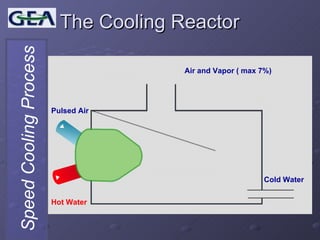

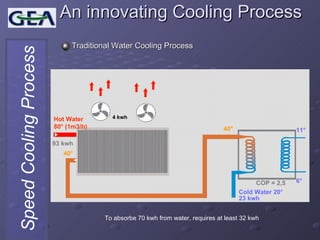

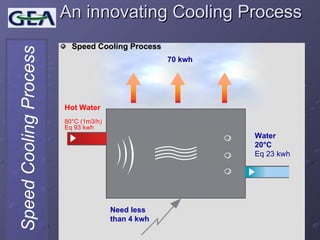

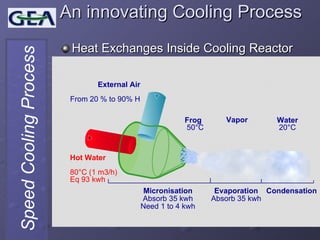

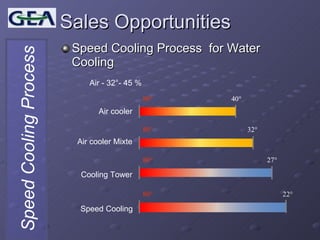

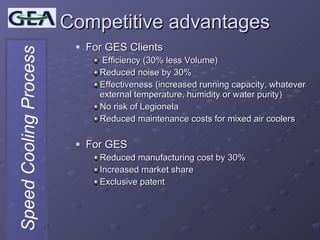

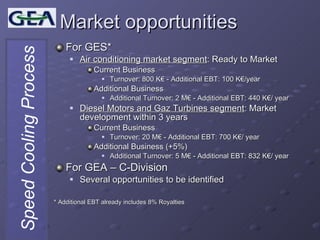

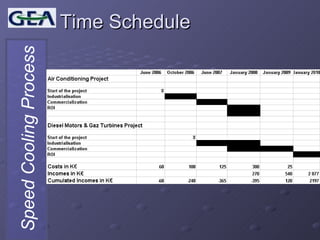

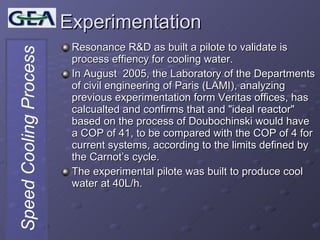

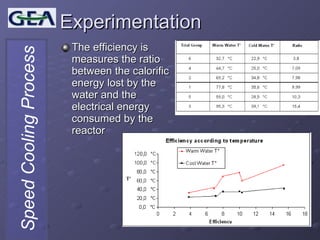

The document outlines an innovative speed cooling process that utilizes vibratory mechanics to create fine water droplets, which vaporize and absorb heat, effectively cooling the environment. Key advantages include reduced noise, higher efficiency, lower maintenance costs, and significant sales opportunities in various markets, including air conditioning and diesel motors. The document also discusses projected returns on investment and development timelines for the technology.