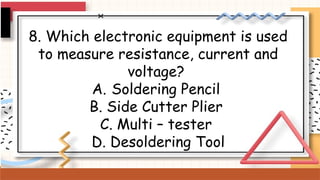

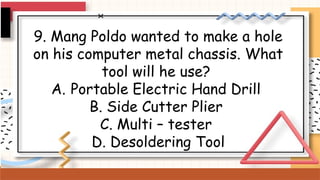

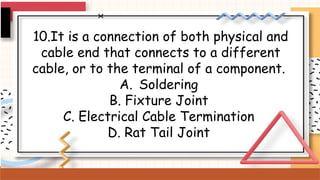

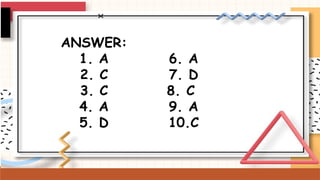

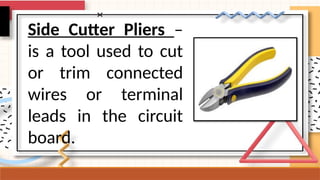

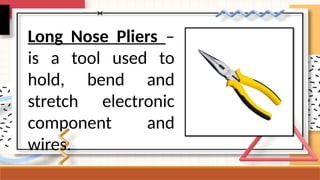

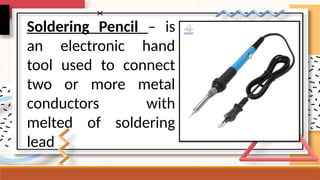

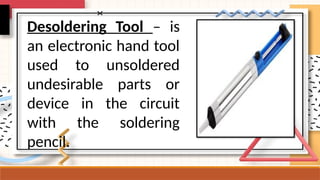

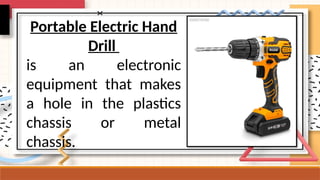

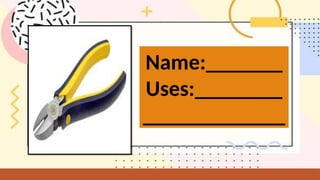

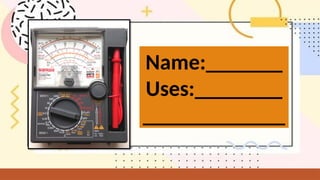

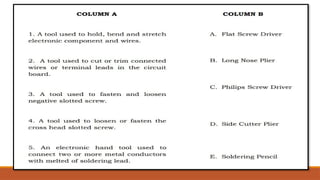

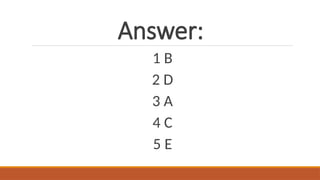

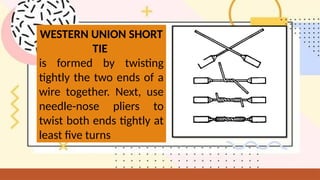

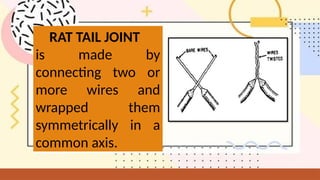

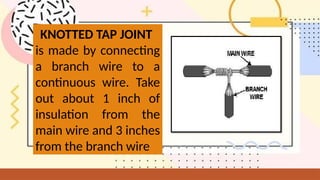

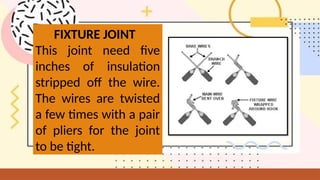

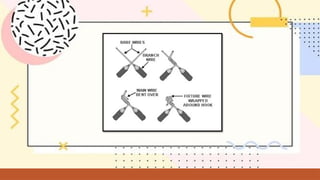

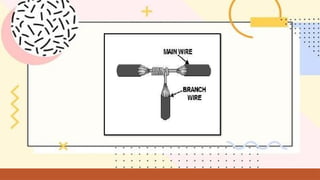

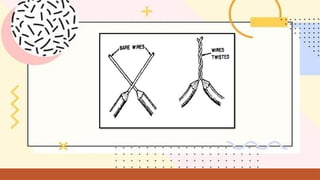

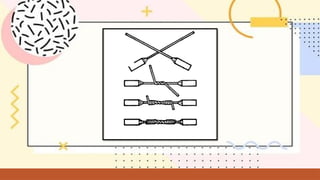

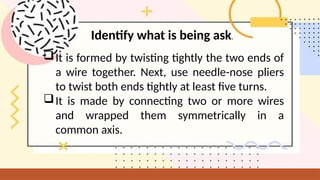

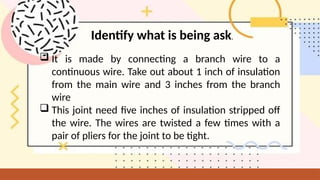

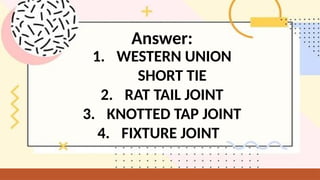

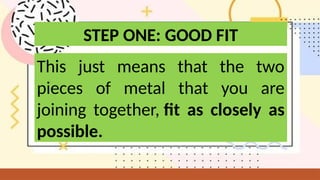

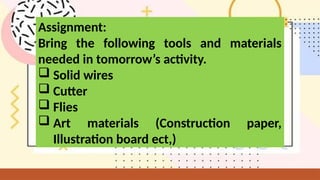

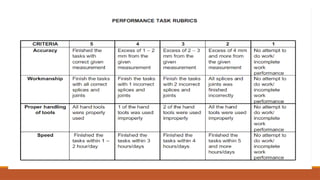

The document is a pre-test and instructional guide for using hand tools in electronic and electrical work, featuring multiple-choice questions on tool identification and their uses. It covers the essential tools and equipment, their applications in tasks like cutting, soldering, and creating wire joints, and includes instructions for hands-on activities. Additionally, it explains the soldering process and emphasizes the importance of proper techniques for effective results.