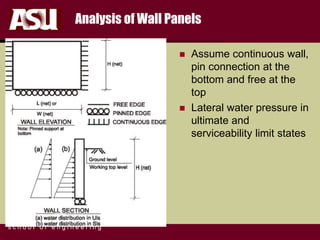

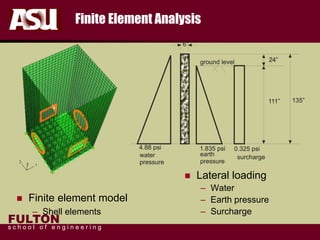

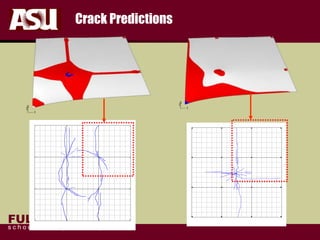

This document discusses the design of precast reinforced concrete structures including precast panels, cast in place water tanks, and fiber reinforced concrete slabs. It outlines the design, analysis, testing, and modeling of these structures. Precast panels are made of concrete and rebar on site and assembled using bolts and epoxy. Finite element analysis is used to model water tanks under lateral loads. Round panel and full-scale fiber reinforced concrete slab tests are conducted and modeled to evaluate post-crack tensile capacity.