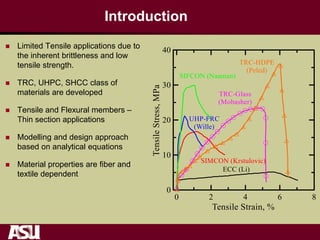

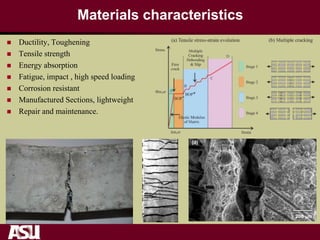

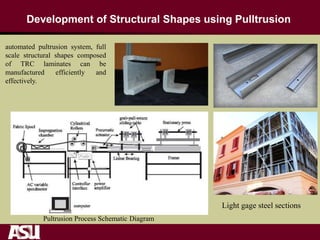

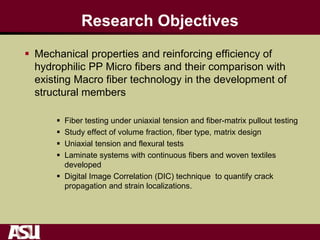

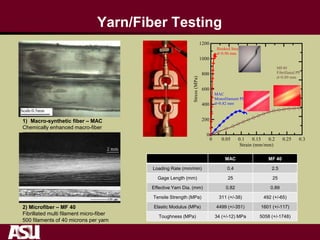

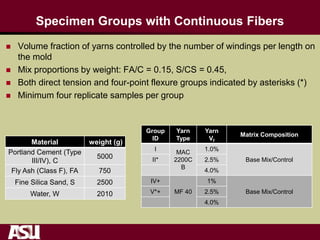

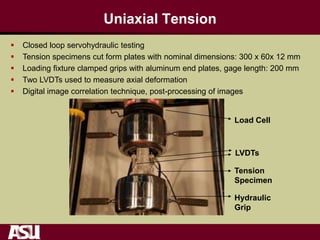

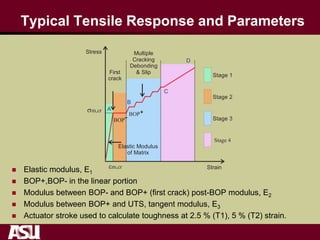

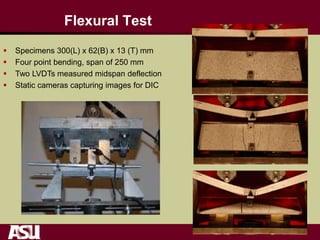

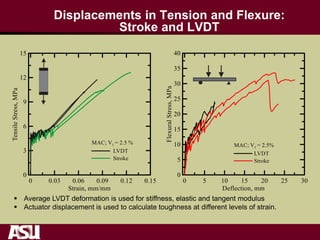

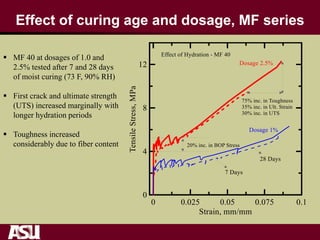

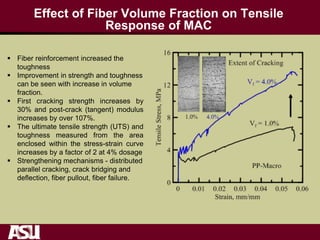

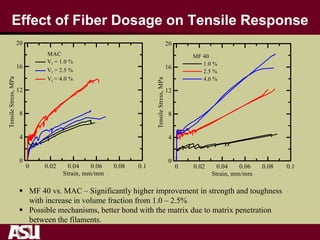

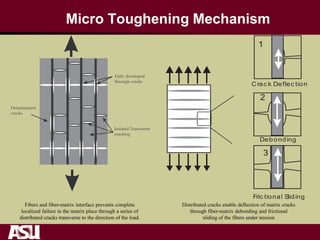

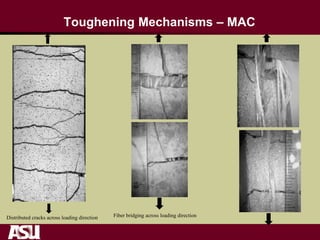

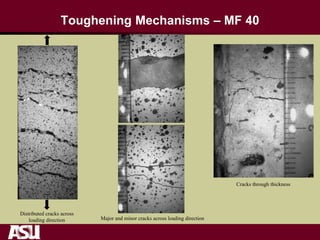

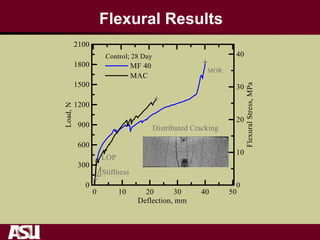

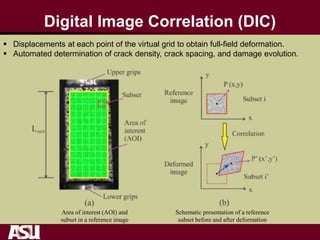

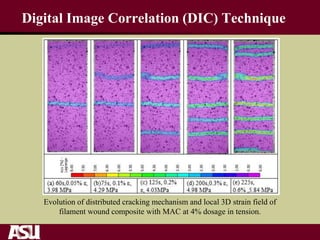

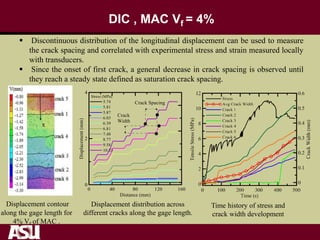

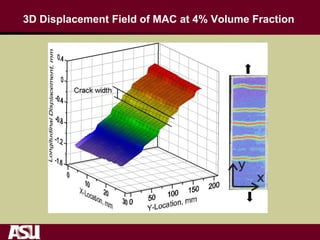

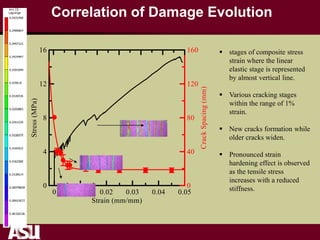

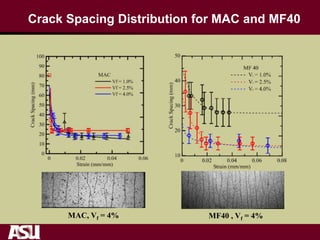

This document discusses research on the mechanical properties of unidirectional polypropylene fiber cement composites. The research aims to study the properties of hydrophilic micro PP fibers compared to existing macro fiber technology in developing structural members. Tension and flexural tests on laminate systems with continuous fibers show that both macro and micro PP fibers increase strength and toughness with higher fiber volumes. Digital image correlation analysis indicates fibers promote distributed cracking and strain hardening behavior through mechanisms like crack bridging and pullout. The continuous fiber composites show potential for thin slab applications if design standards consider their strain hardening properties.