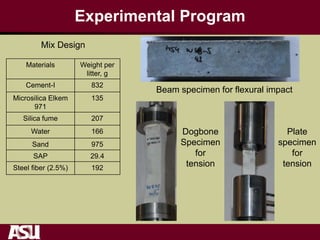

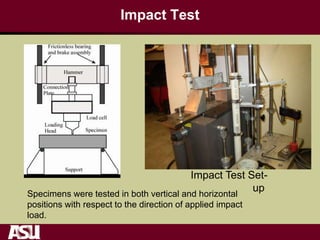

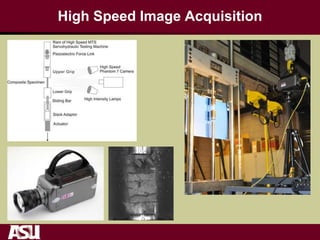

This document summarizes research on the tensile and flexural behavior of ultra-high performance concrete (UHPC) under high-speed and impact loads. High-speed testing systems were used to apply tensile and flexural impact loads to UHPC specimens. Digital image correlation was utilized to analyze crack propagation and strain fields. The research found that UHPC achieved tensile strengths over 20 MPa and flexural strengths exceeding 25 MPa. An analytical model was also developed that could predict UHPC's flexural impact response based on parameters like residual strength, localization zone size, and tensile and flexural properties.