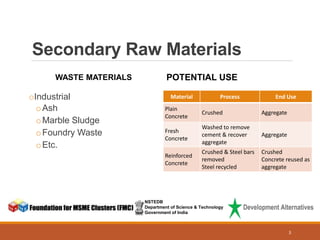

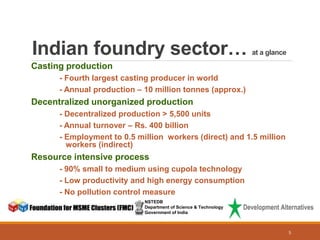

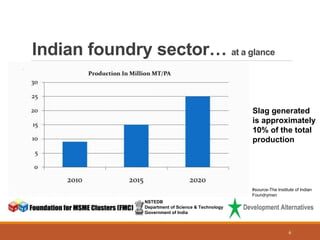

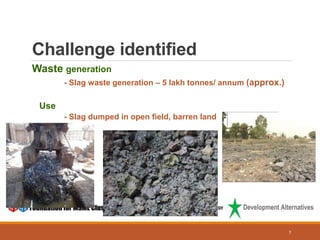

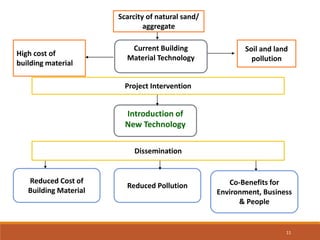

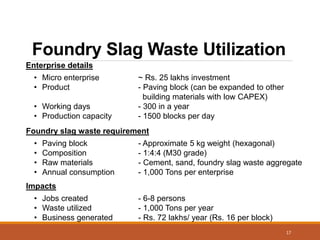

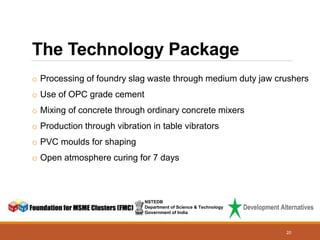

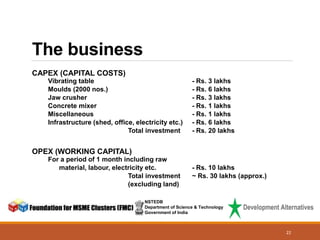

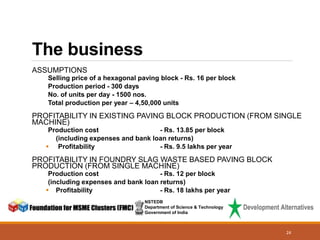

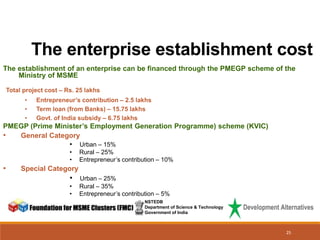

This document discusses the promotion of using foundry slag waste from iron and steel production in foundries as an aggregate in paver block making. It begins by providing background on foundry slag waste and the Indian foundry sector, noting that approximately 5 lakh tonnes of slag waste is generated annually. It then describes the development of a technology to produce paver blocks by completely replacing coarse and fine aggregates with foundry slag. Test results found that paver blocks produced this way met strength standards. The document concludes by outlining the business potential and costs for setting up an enterprise to produce paver blocks using this waste-to-resource process.