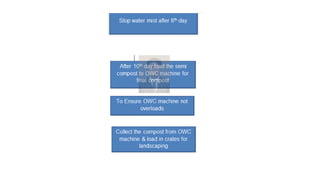

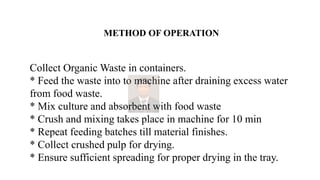

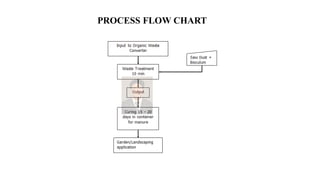

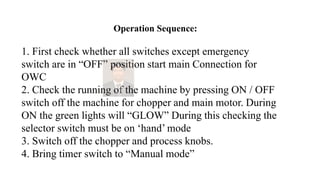

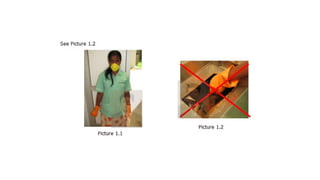

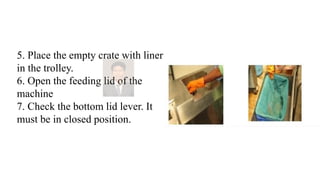

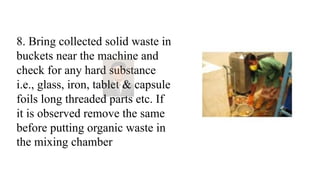

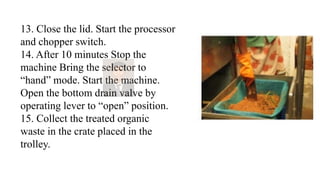

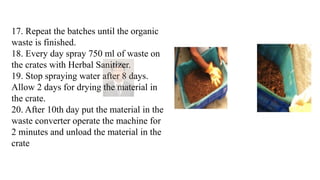

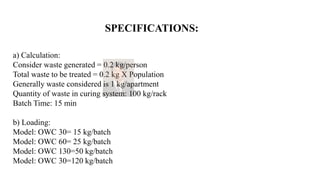

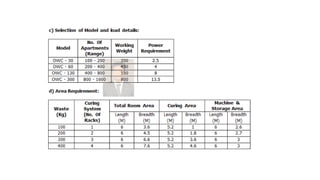

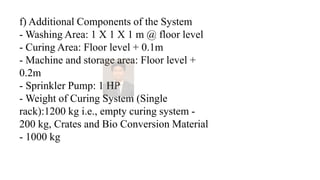

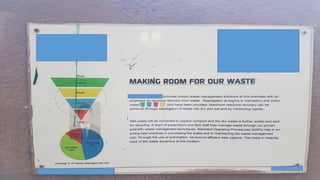

The document provides information on operating an organic waste management unit. It describes the process of collecting, sorting, and treating organic waste using an Organic Waste Converter (OWC) machine. The process involves collecting waste, sorting into dry and wet categories, cleaning areas and machines, feeding waste into the OWC in batches, mixing it with additives, processing it to produce manure, curing the manure, and storing the final product. Safety procedures and personal protective equipment requirements are also outlined to safely operate the waste management unit.