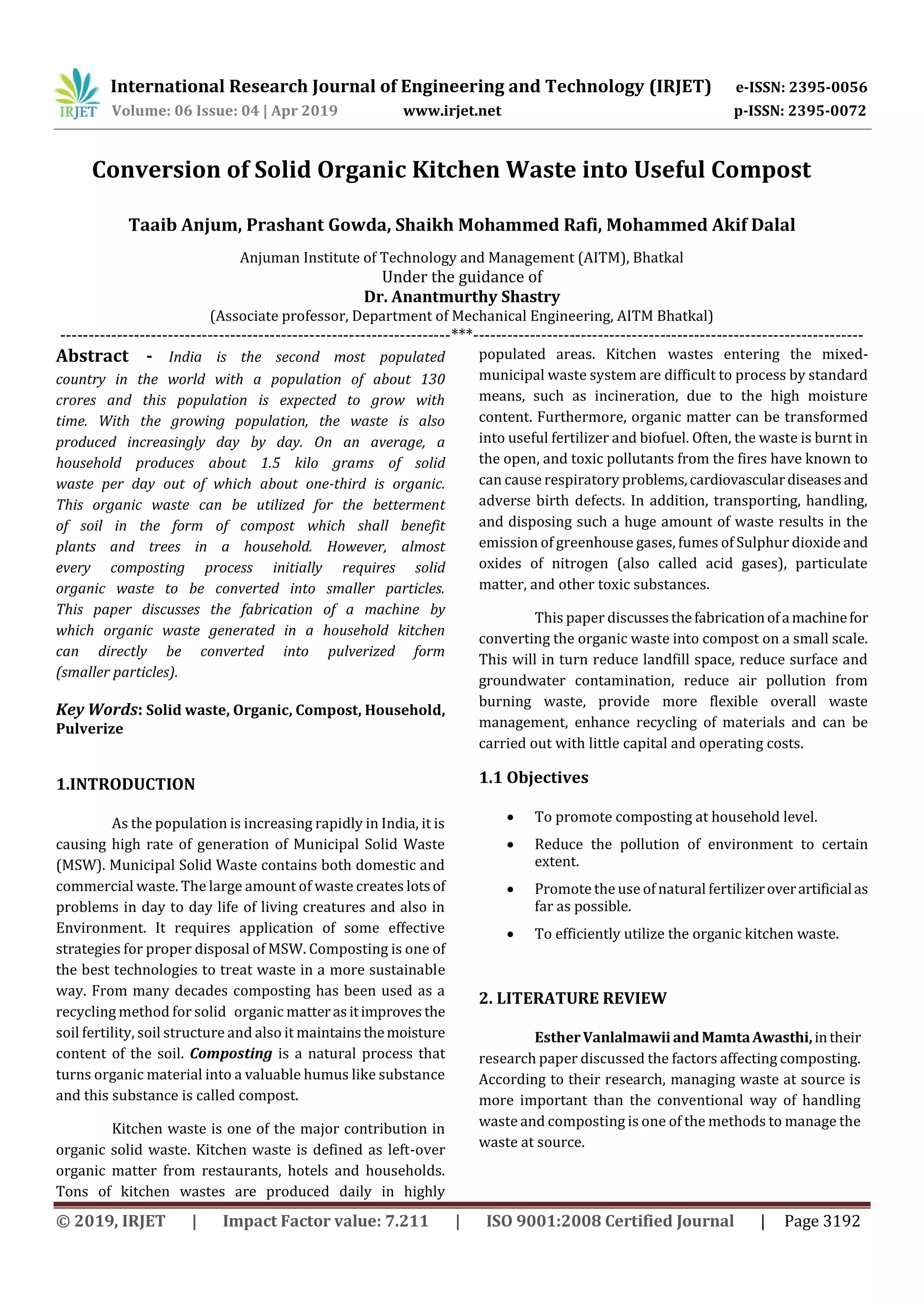

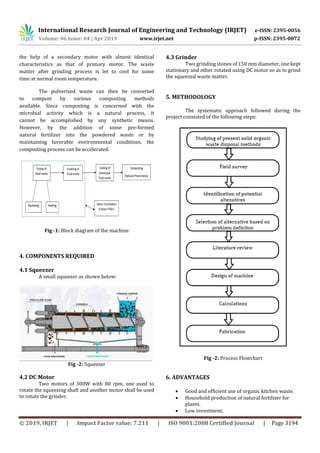

This document discusses the design of a machine to convert solid organic kitchen waste into useful compost. The machine aims to directly pulverize the waste through a squeezing and grinding process. This addresses the initial particle size reduction step required for most composting methods. The machine design incorporates a squeezer to remove water from the waste and two grinding stones - one stationary and one rotating - to pulverize the dried waste into smaller particles. The resulting compost can then be used to improve soil quality and provide nutrients for plants. The machine aims to efficiently utilize kitchen waste on a small household scale while reducing environmental pollution.