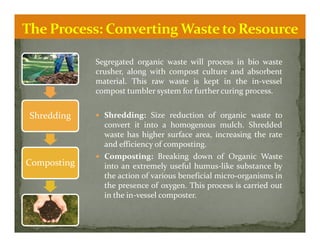

The document outlines the importance of waste segregation and management in Indian cities, highlighting the need for both residents and properties to engage in source segregation of organic waste. It introduces the Spintex compost tumbler, designed for efficient composting of organic waste while minimizing odors and space requirements, and emphasizes the benefits of composting for soil enrichment. Additionally, it discusses the operational process of composting and the equipment involved, as well as promoting awareness about waste management practices among communities.