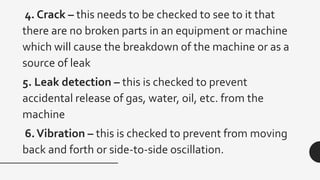

1. The document outlines rules and procedures for proper maintenance and care of equipment. This includes regularly inspecting machines for issues like cracks, leaks, and wear and tear.

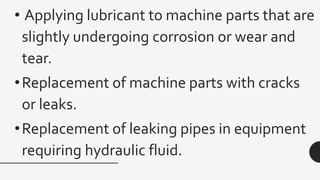

2. Specific maintenance tasks are described for various equipment like pressure cookers, can sealers, freezers, and ovens. This involves cleaning, lubricating parts, and checking for defects.

3. Minor troubleshooting like replacing worn parts is covered. Preventive maintenance like inspections and applying lubricants is also discussed to minimize equipment breakdowns.