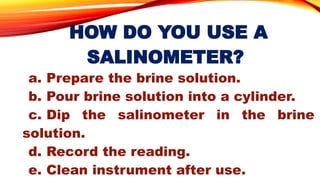

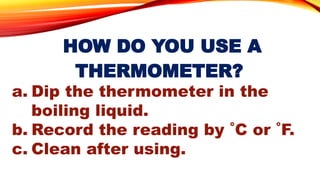

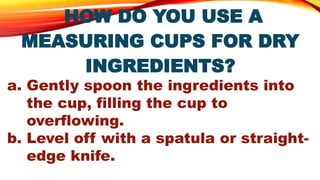

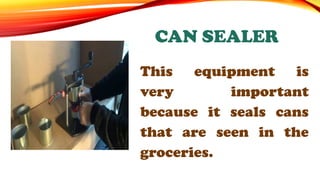

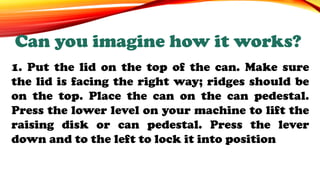

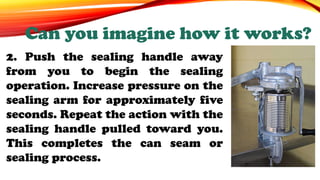

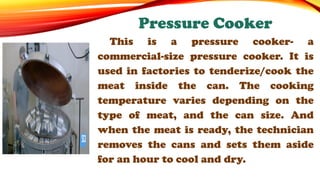

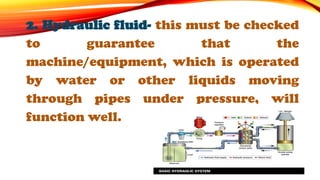

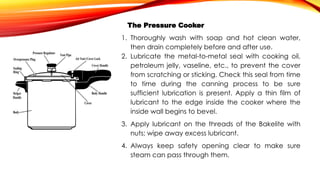

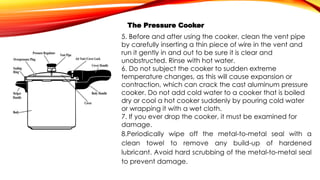

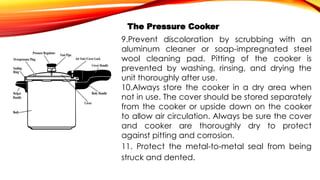

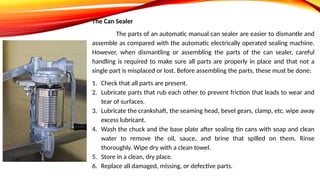

The document outlines the procedures for using and maintaining various food processing tools and equipment, including measuring devices, can sealers, pressure cookers, freezers, and refrigerators. It emphasizes the importance of proper maintenance through regular inspection, cleaning, and lubrication to ensure efficient operation and prevent breakdowns. The text also highlights specific steps for inspecting equipment and performing minor preventive maintenance to enhance serviceability.