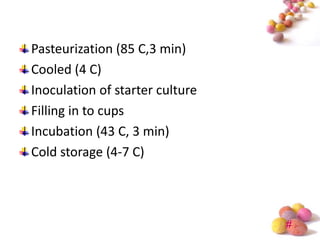

Fonterra Brands Lanka is a subsidiary of New Zealand's largest dairy company, Fonterra Co-operative Group, which is a cooperative owned by over 10,500 farmers and manages about 30% of global dairy exports. The company, established in 2001, produces various dairy products for the Sri Lankan market, including milk powder, yogurt, and liquid milk, and operates with a structured management team overseeing key production processes. It employs specific processing steps for milk powder, raw milk, and set yogurt, involving steps from raw material handling to final product packaging and storage.