The document is a laboratory report that examines how altering the particle size of glass powder compacts affects their density after sintering. Samples of glass powder with different particle size distributions were created, slip-cast into compacts, and sintered at 815°C for 7 minutes. The density of each compact was then calculated. It was found that the sample made of only the finest <200 μm glass powder had the lowest density of 0.184 g/cm3, indicating that smaller particle sizes lead to lower densities after sintering. However, the densities were found to vary within individual compacts, undermining the results. Water absorption tests also showed that more foaming led to a lower density, open-p

![Christopher Parsonson CID 00952857 2

Abstract

The aim of this experiment was to examine the optimum powder size composition needed for the lowest possible density glass

to be produced, preferably lower that 0.12 g cm-3

[3], by varying the particle size within a glass powder compact. This was done

through sintering soda-lime glass compacts of different powder size at a high temperature of 815 °C for 7 and 5 minutes so as to

cause foaming, allowing for each sample’s density to be calculated and porous microstructure to be examined. Overall, it was

found that altering the particle size within the compact changed the final density in that the smaller the powder diameter, the

lower the density, with the sample made of only the finest <200 µm having the lowest density at 0.184 g cm-3

. However, by

looking at the compacts’ cross-sections and by measuring the densities of different parts, it was also found that the density of the

compacts varied throughout their structure, possibly due to the heating inconsistencies in the furnace, the water draining

mechanism during slip casting or simply the experimental error, therefore possibly undermining these results. Additionally,

through recording water absorption, it was found that a greater degree of foaming led to a low-density open-pore structure in

which water may be trapped, therefore reaffirming the established theory.

Introduction

Throughout history, the science of materials and of their properties has been extremely useful in engineering applications, and

this only becomes increasingly apparent with modern technological advances. One such family of materials that have shaped

the world around us is that of glass. Glass is a particularly interesting material because although it has a local order, its general

structure is that of an amorphous brittle solid [1]. This amorphous characteristic makes it easier to remove and replace atoms

and ions in order to manipulate its properties than it would otherwise be in a crystalline material. Indeed, it is this fact that

enables glass to be used across a broad range of engineering applications. Be it in the corrosion resistant “self-cleaning” glass of

the shard, the scratch-immune high strength gorilla glass of the modern day iPhone or the low-density to high-strength ratio

3MTM

Glass Bubble technology of undersea gas recovery operations [2], glass is a fundamental part of society, and an

understanding of how it may be processed to acquire various properties is crucial for materials engineers in order to continue to

advance this exciting area of science.

There are three primary methods for glass processing: molten casting, glass blowing and sintering [3]. This report shall focus

on the use of sintering in low-density sol-gel derived glass production. A sol-gel is simply a dispersion of colloidal particles

within an interconnected rigid open network swollen by water. A fine-powder glass is mixed with water to create a slip/sol-gel

through polymerisation condensation, a process known as “gelation”. During this process, a catalyst is often added to adjust the

pH of the solution and thus determine the type of powder produced. An acidic catalyst will lower the pH of the solution below

the isoelectric point (the point at which the effective charge in the solution is 0 [4]), causing the particles to be attracted to

oneanother and creating a glass powder of “large” particles. A basic catalyst will cause the pH to rise above the isoelectric

point, resulting in the particles repelling oneanother and creating a glass powder of very small nano-sized particles [5]. The

sample is then slip-cast and dried in order to evaporate water droplets and leave pores where water was once present. During

drying, the weak bonds formed by mechanical interlocking and van der Waals forces during condensation shrink and the

porosity reduces, forming a “glass powder compact”.

The final stage in this method of glass production is sintering. Sintering is a process whereby the glass compact is heated

above its transition temperature (Tg ≈ 575-650 °C), causing the structure to relax and undergo viscous flow (the continuous

steady motion of particles within a material [6]). In a sol-gel derived glass, this allows for tertiary particles (that have formed as

a result of the aggregation of secondary particles within the wet gel) to fuse together, increasing the density of the glass. The

high temperatures used during sintering evaporate much of the remaining water within the gel structure, leading to further

shrinkage of bonds and reduction in porosity and thus an additional increase in density. If the sintering conditions are suitable,

however, the compact will undergo glass foaming.

Glass foaming allows for the production of very low-density glass. To foam a glass, the compact must be heated to very high

temperatures in order for rapid sintering to occur at the surface of the compact before the centre has time to undergo much

viscous flow, forming what is referred to as a primary melt; essentially a surface layer of liquid glass phase [7]. This primary

melt traps or “seals” the air present within the compact’s pores that formed during drying, preventing it from escaping and

creating “gas bubbles”. As the sample is heated and the glass melts, these air particles gain energy and increase the internal

pressure of the glass through collisions with the pore walls as they “try” to escape into the atmosphere, thus expanding the

pores through gas bubble expansion. As these pores grow in size, the volume of the glass increases and therefore the density

decreases, thus producing a low-density glass. This process is shown in Figure 1.](https://image.slidesharecdn.com/736f8379-bbed-49f0-86a2-fe3fa5e3d3b7-161018135028/85/Foamed-Glass-Extended-Lab-Report-2-320.jpg)

![Christopher Parsonson CID 00952857 3

As is shown in Table 1, if sintering is carried out at the usual aforementioned temperature range, no foaming occurs and the

density increases. If, however, it is carried out at a higher temperature range, a degree of foaming is observed through the

reduction in density. For a glass to be amorphous, it must not exceed its crystallisation temperature (Tc ≈ 775 °C) shown by the

general differential thermal analysis (DTA) scan in Figure 2, therefore care must be taken not to make the sintering temperature

too high so as to cause crystallisation or too low so as to prevent foaming.

Figure 2: General glass DTA trace showing

the glass transition (Tg), the crystallisation

temperature (Tc) and the window in which

sintering/foaming of the glass may operate

[1].

Figure 1: Schematic

showing the process of

glass foaming [7].

Table 1: Observations made of the

influence of temperature on glass powder

compact samples [3].](https://image.slidesharecdn.com/736f8379-bbed-49f0-86a2-fe3fa5e3d3b7-161018135028/85/Foamed-Glass-Extended-Lab-Report-3-320.jpg)

![Christopher Parsonson CID 00952857 4

During low-density glass production, the degree of foaming that takes places is very important in determining the quality

and the properties of the final product. The density may be reduced to a point where the sealed air inside the pores of the

compact is at thermal equilibrium with the surrounding environment, thus maintaining closed pores within the structure. At

this point, the strength to density ratio of the glass will be at its greatest, therefore if a low-density glass with high compressive

strength is required, the sample should be removed from the furnace. Continued heating at a necessarily elevated temperature

will result in the internal pressure exerted by the expanding gas bubbles of the pores becoming great enough for them to burst

open, allowing the air to escape and essentially causing the pores to join up and create larger pores, therefore further decreasing

the density. Continued expansion will form an open structure of channels through which air may exit into the atmosphere. This

is a process known as piercing [3]. Glass that has undergone piercing will have a lower thermal conductivity due to greater pore

size and therefore will have greater insulating properties, however this will be at the cost of a lower compressive strength.

Additionally, too many open channels allowing air to escape may impede insulation. Therefore, it is essential for the foaming

process to be adequately tailored to produce a product that meets the properties required for its application.

Three simple ways to vary the foaming process are through varying the sintering temperature, the sintering time and the glass

particle size [7]. This report shall focus on the latter. If three glass powder compacts are considered; one (sample a) consisting of

100% “large” particle size (>200 µm in diameter), one (sample c) consisting of 100% “small” particle size (<200 µm in

diameter) and finally one (sample b) consisting of a mixture of large and small particle sizes, a diagram of what their structures

might look like may be drawn, as shown in Figure 3.

Figure 3: Diagram of glass powder

compacts with varying particle size

[7]:

a) 100% large (>200 µm in

diameter) particle size.

b) Mixture of large & small

particle size.

c) 100% small (<200 µm in

diameter) particle size.

Figure 3 shows that the stacking of the large particle size in a results in the biggest vacancies being present. The stacking of

the smaller particles in c is closer and therefore creates smaller vacancies, and the stacking in mixed sample b is closer still, with

the smaller particles filling the large vacancies created by the larger particles. Thus, in terms of vacancy size, b < c < a. It would

therefore be expected for the larger particle compacts to have the lowest density at 0 minutes of sintering and for the mixed

particle compacts to have the highest density, as shown in Figure 4. The same relationship applies for the respective maximum

densities. Additionally, as discussed in an experiment carried out by AZO Materials [8], due to the initial vacancies after foaming

the final frequency of pores within the smaller samples would be the greatest, followed by the mixed powders and finally by the

large compacts (holding the lowest number of pores). Due to the stacking shown in Figure 3, the large particles would be

expected to have the largest pore diameters.

Figure 4 also shows that during the sintering process, a constant density is eventually reached, which occurs when either (as

previously explained) the pores are at equilibrium with their environment or if the maximum amount of piercing has occurred

so that no expanding air/gas bubbles are left trapped within the pores. As this is the point of lowest density during the foaming

process, it is this part of the process that will be focused on in this report.

Interestingly, Figure 4 also shows that despite the mixed particle size compact having the greatest initial and maximum

density, it would be expected for it to have the lowest final (constant) density after foaming. According to X. Song’s 2014 student

thesis [7], this occurs because the pores in the mixed particle compact are able to expand to a greater extent than in the other

compacts. Additionally, the minimum density is reached in the mixed compact after a shorter sintering time than the other two

compacts. This is perhaps due to the wall strength of the pores/vacancies being greater due to the presence of small particles

within the large vacancies created by the large particles. This report will aim to further clarify this theory of somewhat limited

reliability.](https://image.slidesharecdn.com/736f8379-bbed-49f0-86a2-fe3fa5e3d3b7-161018135028/85/Foamed-Glass-Extended-Lab-Report-4-320.jpg)

![Christopher Parsonson CID 00952857 5

Figure 4: Graph of recorded

bulk density vs.

heating/sintering time for

compacts of varying particle

size [7].

Up to this point, it has been (roughly) established that a general mixture of particle size within a compact enables for a

foamed glass to have the lowest density. What has not been clearly determined, however, is the optimum variation in particle

size within the composition needed for the absolute lowest density to be reached (below 0.12 g cm-3

[3]), which is an important

question to answer when considering the use of low-density glass in low-quality recycled glass products, and this is therefore

what this report shall specifically look into.](https://image.slidesharecdn.com/736f8379-bbed-49f0-86a2-fe3fa5e3d3b7-161018135028/85/Foamed-Glass-Extended-Lab-Report-5-320.jpg)

![Christopher Parsonson CID 00952857 6

Experimental

The experiment began by taking a series of fine to coarse soda-lime glass powders of diameters 1,000-600 µm, 600-400 µm, 400-

200 µm and <200 µm. The powders were a raw material made from commercial recycled glass aggregates using a vibratory mill

containing aluminium oxide milling cylinders. As shown in Table 2, slips of varying composition were prepared by using the

approximate ratio of 5 g of powder to 2 g of water. For 3 mixed powders, around 10% of the compact consisted of >200 µm

powder with the rest being made up of <200 µm powder. The pure powders contained 100% of just one powder, and the final

mixed powders contained an incrementally increasing % 200-400 µm powder in bulk <200 µm. Note that no catalyst was used.

The slips were then cast by placing them in an open mould with a plasterboard base used to absorb the water, as shown in

Figure(s) 5. The casts were left to dry for 7 days, after which they were carefully removed so as not to break the weak

mechanical interlocking and van der Waals forces holding them together, and placed in a furnace to sinter and foam at varying

conditions, as shown in Table 3 and Table 6. Using the prior observations made in Table 1, a sintering temperature of 815 °C for

7 and 5 minutes were chosen. To spread the available powder resources, the 7-minute sintering time data were used from

another student’s experiment [9].

The green body density was then calculated by breaking off part of a given sintered glass compact sample, grinding it to a

regular cubic/rectangular shape and measuring its dimensions using a Vernier calliper. The samples were left to re-dry for 2

hours before their masses were measured and Equation 1 was used to calculate the density, as is shown in Table 3.

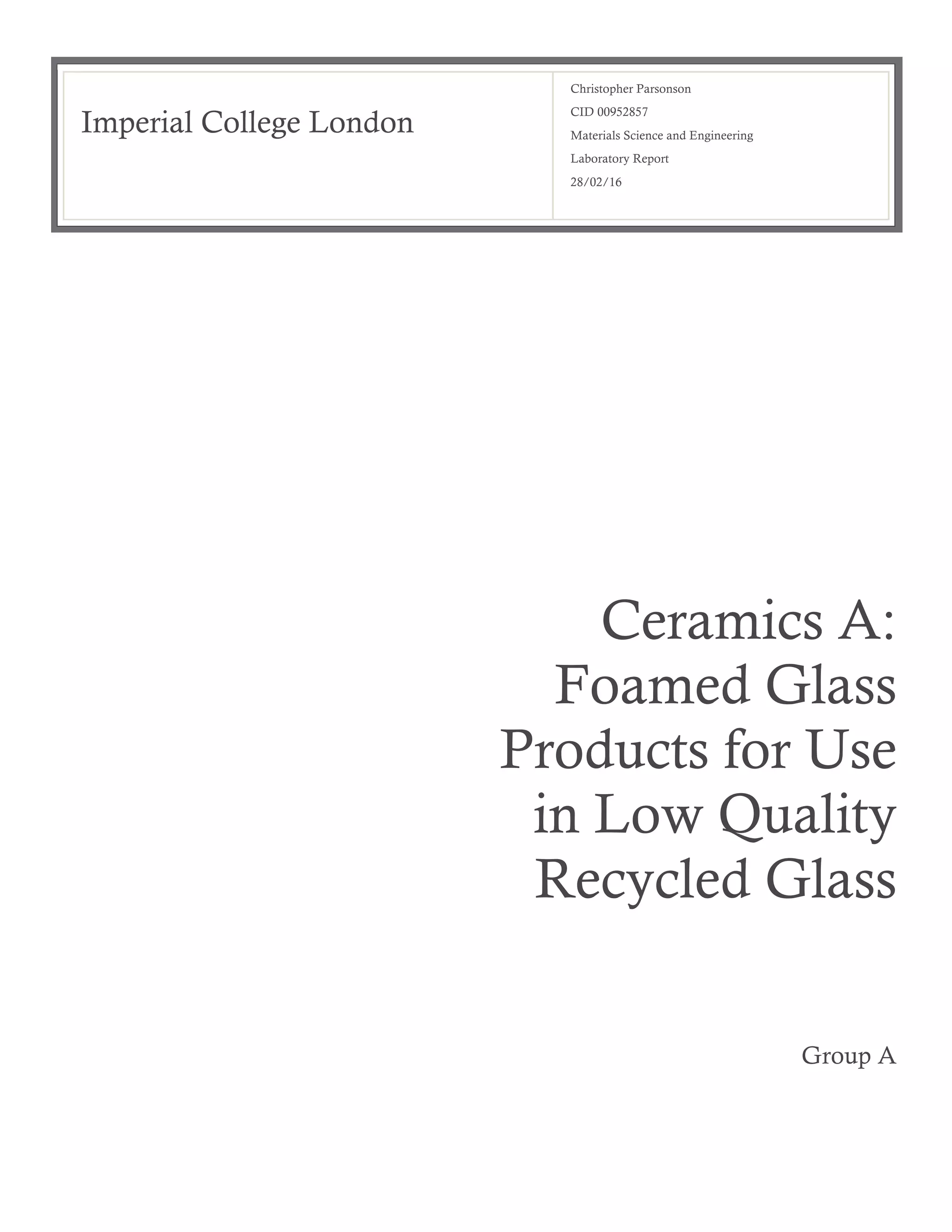

Finally, using the ground glass compact samples and a stereomicroscope (used because the optical microscope struggled to

focus on individual pores due to focal length issues), the pore size/distribution of the glass was examined and calculated using

MATLAB in order to observe the degree of foaming that had occurred during sintering. Additionally, two samples (the two

100% <200 µm glass powders) were submerged in water for 24 hours and re-weighed in order to observe the amount of water

absorption that would occur. Samples of the same <200 µm composition that had been sintered but not submerged were then

placed back in the furnace at 1,000 °C for a further 10 minutes to see if there was any additional foaming/change in density

and, if so, by how much this changed.

Results

As outlined in the experimental section of this report, slips of varying composition were mixed, as shown in Table 2.

Sample <200 µm Powder

(g)

200-400 µm

Powder (g)

400-600 µm

Powder (g)

600-1,000 µm

Powder (g)

Water (g)

X 0.00 0.00 0.00 5.02 2.15

1 0.00 5.00 0.00 0.00 2.24

2 5.07 0.00 0.00 0.00 2.02

3 5.04 0.00 0.00 0.00 2.10

4 4.53 0.685 0.00 0.00 2.10

5 4.63 0.00 0.00 0.53 2.00

Table 2: Table showing the composition of each glass compact sample made for 7 minute sintering at 815 °C.

The glass compacts were then slip-cast and left to dry for 7 days on a plasterboard, as shown in Figure(s) 5.](https://image.slidesharecdn.com/736f8379-bbed-49f0-86a2-fe3fa5e3d3b7-161018135028/85/Foamed-Glass-Extended-Lab-Report-6-320.jpg)

![Christopher Parsonson CID 00952857 7

Due to its crumbling after removal from the mould, Sample X could no longer be used for the duration of the experiment.

As mentioned in the experimental, Samples 1-5 were placed in a furnace set at 815 °C and left for 7 minutes to sinter and foam

before being removed, cooled and ground into a cubic/rectangular shape, allowing for their densities to be calculated as shown

in Table 3. Defining the glass compacts as green bodies (meaning a weakly-bonded ceramic material often in the form of a

powder [10]), the “green” or “bulk” density (which is inclusive of solid particle, liquid and empty pore/vacancy volume [11])

could be calculated using Equation 1.

𝐷𝑒𝑛𝑠𝑖𝑡𝑦 =

!"##

!"#$%&

(Equation 1)

Sample Mass (g) Width (mm) Length (mm) Thickness (mm) Green Density

(g cm-3

)

1 0.5289 10.52 11.66 6.39 0.6748

2 0.0808 8.47 7.36 7.04 0.1841

3 0.3206 12.64 11.68 7.45 0.2915

4 0.2301 11.71 10.44 9.43 0.1996

5 0.3780 12.26 10.26 9.93 0.3026

Table 3: Table showing the dimension, mass and final calculated density of each compact sample after foaming at 815 °C for 7 minutes.

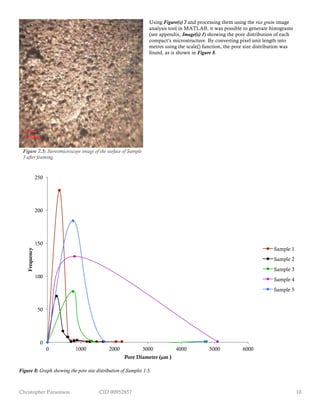

These data may be easily represented and compared graphically using a bar chart to give the lowest density compact as being

Sample 2, as shown in Figure 6. With Samples 2 & 3 having the same composition but with a density that differed by ≈60% (in

that Sample 2 had a significantly lower density than Sample 3), it was decided for further testing to be carried out. As stated in

the experimental, another part of the already sintered Samples 2 & 3 were broken off and foamed for a further 10 minutes at

1,000 °C to see if perhaps Sample 3 had not foamed as much as it could have otherwise. These new versions of Sample 2 and

Sample 3 were named Sample 2.1 and Sample 3.1 respectively, and the density calculations after further foaming are shown in

Table 4.

Figure 5.1: Image showing the samples in their cast having

been dried by the water draining into the plasterboard lying

below.

Figure 5.2: Image showing the samples having been removed

from their cast, leaving a green body glass compact.](https://image.slidesharecdn.com/736f8379-bbed-49f0-86a2-fe3fa5e3d3b7-161018135028/85/Foamed-Glass-Extended-Lab-Report-7-320.jpg)

![Christopher Parsonson CID 00952857 12

Discussion

Before analysing the results of this experiment, it is important to look at potential sources of uncertainty and unreliability in the

data. To begin with, the pore diameter distribution in Figure 8 will likely be somewhat inaccurate due to the presence of bright

light anomalies in Figure(s) 7 as a result of the light source used in stereomicroscopy. These bright patches will distort the

detection of pores by MATLAB, therefore affecting diameter measurements. As optical microscopy gave unclear images due to

the difficulties in focusing on a very porous material, a more accurate method to examine the microstructure and subsequently

the pore size and distribution of the compacts would be SEM, which (with its high-quality images) would be useful for image

analysis in MATLAB.

Furthermore, human error led to the time for each sample to be put in and removed from the furnace to vary, therefore

resulting in some samples to be foamed for longer than others. Additionally, having the furnace open before sintering to place

the glass compacts inside led to temperature drops, which subsequently took time for the desired 815 °C to be reached again

when the furnace was shut. This would have meant that although the quoted sintering times for the compacts were 5 and 7

minutes at 815 °C, in reality the time spent sintering at 815 °C would have been less.

Finally, the samples were left to dry for just a few hours after grinding (in the presence of water) before being reweighed. This

may not have given enough time for the water to drain completely, therefore the calculated green densities will have been

slightly higher than those of the actual glass powder compacts. A more effective drying method would have been to place the

samples back in the furnace at ≈100 °C, which would not have affected the soda-lime samples because it is much below any

transition temperature (see introduction), but would have evaporated the leftover water properly.

It is worth noting the failure of Sample X (100% 600-1,000 µm powder compact) in that it crumbled immediately when

removed from the mould. This was most likely due to the powder having a density of 2.52 Mg m-3

compared to that of water at

1 Mg m-3

. The larger the particles, the greater their masses and the harder it will be for water to aid in the formation of weak

bonds to hold the heavy structure together. Future experiments should take this into consideration and perhaps mitigate against

it by arranging the powder within the mould first before pouring water over the top to ensure that the water slowly drains

through the compact, forming as many bonds as it can before being absorbed at the base by the plasterboard [3]. Alternatively,

as outlined in the introduction of this report, including an acidic catalyst would attract the particles to oneanother; therefore its

addition should be considered when trying to keep the coarse powders from breaking apart.

By the end of the experiment, the sample with the lowest density was Sample 2 at 0.1841 g cm-3

, as is shown in Figure 6. Figure

6 also shows, however, that despite Sample 2 and Sample 3 being of the same composition (100% <200 µm powder) and having

been subjected to the same sintering conditions (815 °C for 7 minutes), their densities at 0.1841 g cm-3

and 0.2915 g cm-3

respectively differed by ≈60%. This inconsistency is verified by Table 4, which shows that after further heating of parts taken

from bulk Sample 2 and Sample 3, Sample 3 (renamed Sample 3.1) instead now has a lower density than Sample 2 (renamed Sample

2.1). The most likely reason for this is that there is a variation in density throughout the whole glass compact sample, therefore

if one part of the sample is broken off, ground and measured, it will likely have a different density from another part. This

variation in density may be due to different amounts of foaming occurring throughout various sections of the material. Indeed,

if the block-like samples in Figure(s) 5 (before foaming) are compared to the arc-like sample in Image 2.1 (which all samples

appeared like after foaming; see appendix), it is clear that the shape has changed considerably, suggesting a greater degree of

foaming at the centre/top of the sample than at the edges/bottom. A cross-section of this is shown in Image 2.2 (see appendix),

which (as marked) shows a clear variation in porosity (and therefore density) from top to bottom. One explanation for this is

that when the samples were slip-cast, the water would be drawn by gravity to the base of the sample where it would slowly be

absorbed. The greater time over which water was present at the bottom of the sample relative to the top may have allowed for

more bonds to form, therefore making the pore walls more difficult for gas bubbles to pierce during foaming and thus leading to

smaller pores (and therefore a higher density). Alternatively, the ceramic pot used to hold the compacts during foaming may

have acted as an insulator and taken a longer time to heat up, therefore the top of the sample that was not in contact with the

pot could have been heated to a higher temperature than the bottom and therefore have undergone a greater degree of foaming,

thus giving the top of the sample a lower density.

Table 5 shows that Sample 2 (lower density) absorbed significantly more water than Sample 3, with its mass increase being

more than three times that of the latter. This suggests that Sample 2 had more pierced open pores and open channels through

which water may be absorbed, and that Sample 3 contained more closed pores. This confirms the theory outlined in the

introduction that an open-pore network will lead to a lower density glass.](https://image.slidesharecdn.com/736f8379-bbed-49f0-86a2-fe3fa5e3d3b7-161018135028/85/Foamed-Glass-Extended-Lab-Report-12-320.jpg)

![Christopher Parsonson CID 00952857 13

Figure 8 is interesting in that it contradicts the unconfirmed prediction made in the introduction of this report that compacts

made of smaller powders will have a lower pore size but a greater frequency than those made of larger powders, with Sample 2

and Sample 3 (made of the finest powders) containing the least number of pores of all the samples. This could be due to the

particles of the smaller-powder samples being stacked closer together (see Figure 3) and therefore having a greater bond strength,

which would make it more difficult for piercing to occur. Alternatively, the close stacking could have allowed less water to be

present within the structure after casting, therefore leaving fewer pores when dried. A lower pore frequency would, however,

undermine the conclusion drawn from Figure 6 that the small powder samples underwent more foaming which led to a lower

density, therefore a perhaps more likely explanation is that the previously outlined poor quality images of Figure(s) 7 resulted in

inaccurate calculations made by MATLAB, reaffirming that SEM images should be taken for future experiments.

Figure 9 shows as the fraction of larger particles increases within a compact that is formed mainly by smaller particles, that the

density will also increase. What is interesting is that the lowest density (0.301 g cm-3

) occurs with a mixture made of 10% 200-

400 µm and 90% <200 µm powder, rather than the 100% <200 µm (which, when sintered at 815 °C for 5 minutes, had a density

of 0.478 g cm-3

) as was found to be the case for glass sintered at 815 °C for 7 minutes (in which the lowest density achieved was

0.184 g cm-3

, as shown in Figure 6). This might suggest that small powders take a longer time to foam, which would be logical

as they initially have the highest density due to their stacking (see Figure 3), and therefore need a greater reduction in density

than larger powder samples. Alternatively, this result could be because the prediction made in the introduction that mixed

powders may undergo the greatest amount of foaming is correct. Ultimately, a certain conclusion is difficult to draw due to the

previously established uncertainty in there being a varying density throughout a single compact. In order for the sample with

truly the lowest density to be found, a future experiment that uses more samples to increase reliability and decrease the

uncertainty that results due to density variation should be carried out.

As well as what has been discussed, there are a few further points that could be made to improve future experiments looking

into the effect of glass compact powder size on the foaming process. One limitation in this report was that there was a finite

amount of <200 µm that was used by the group very quickly and therefore the number of samples used was not high enough to

gain reliable data. Future attempts should ensure that there is a necessary quantity of powder available and aim to make more

samples to make more reliable conclusions. If later experiments establish that a lower powder size gives a lower density (as it

was in Figure 3), it would be interesting to see if mixing in larger powders improves the mechanical properties by introducing

strains in the structure, as is the technique in creating high-strength gorilla glass [1].

Conclusion

In conclusion, this experiment has demonstrated how the sintering process in glass production can be used to foam glass

compacts into very low-density materials. It was found that altering the particle size within the compact changed the final

density in that the smaller the powder diameter, the lower the density, with the sample made of only the finest <200 µm having

the lowest density at 0.184 g cm-3

. However, it was also found that the density of the compacts varied throughout their

structure, possibly due to the heating inconsistencies in the furnace, the water draining mechanism during slip casting or simply

the experimental error. It was therefore decided that adjustments to the experiment should be made and that more samples

should be tested to allow for a more reliable conclusion to be drawn. Overall, the aims laid out in the abstract section of this

report of varying particle size within a glass powder compact to examine the optimum variation needed for the lowest possible

density glass to be produced were achieved, and to this extent this has been a successful experiment.](https://image.slidesharecdn.com/736f8379-bbed-49f0-86a2-fe3fa5e3d3b7-161018135028/85/Foamed-Glass-Extended-Lab-Report-13-320.jpg)