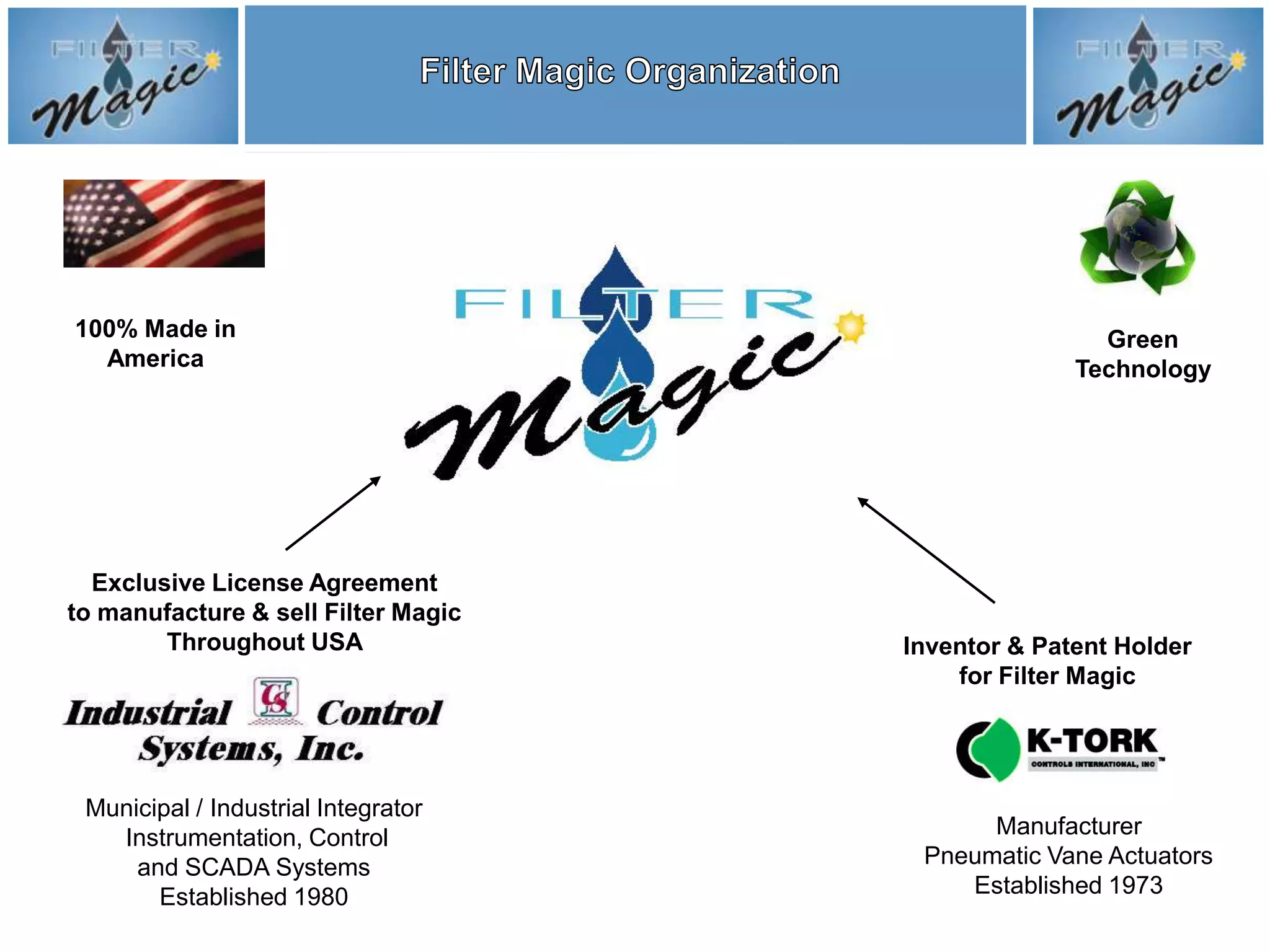

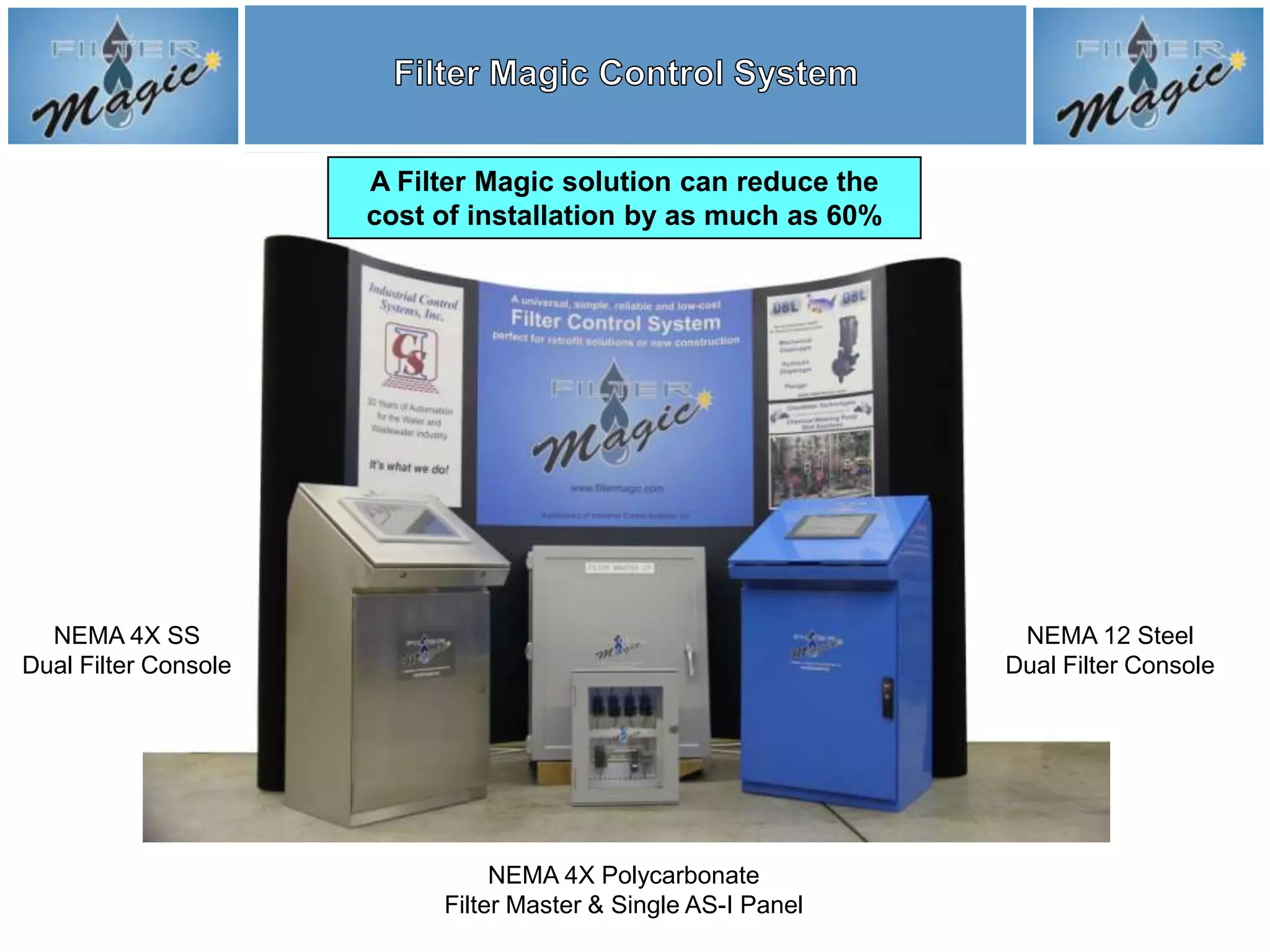

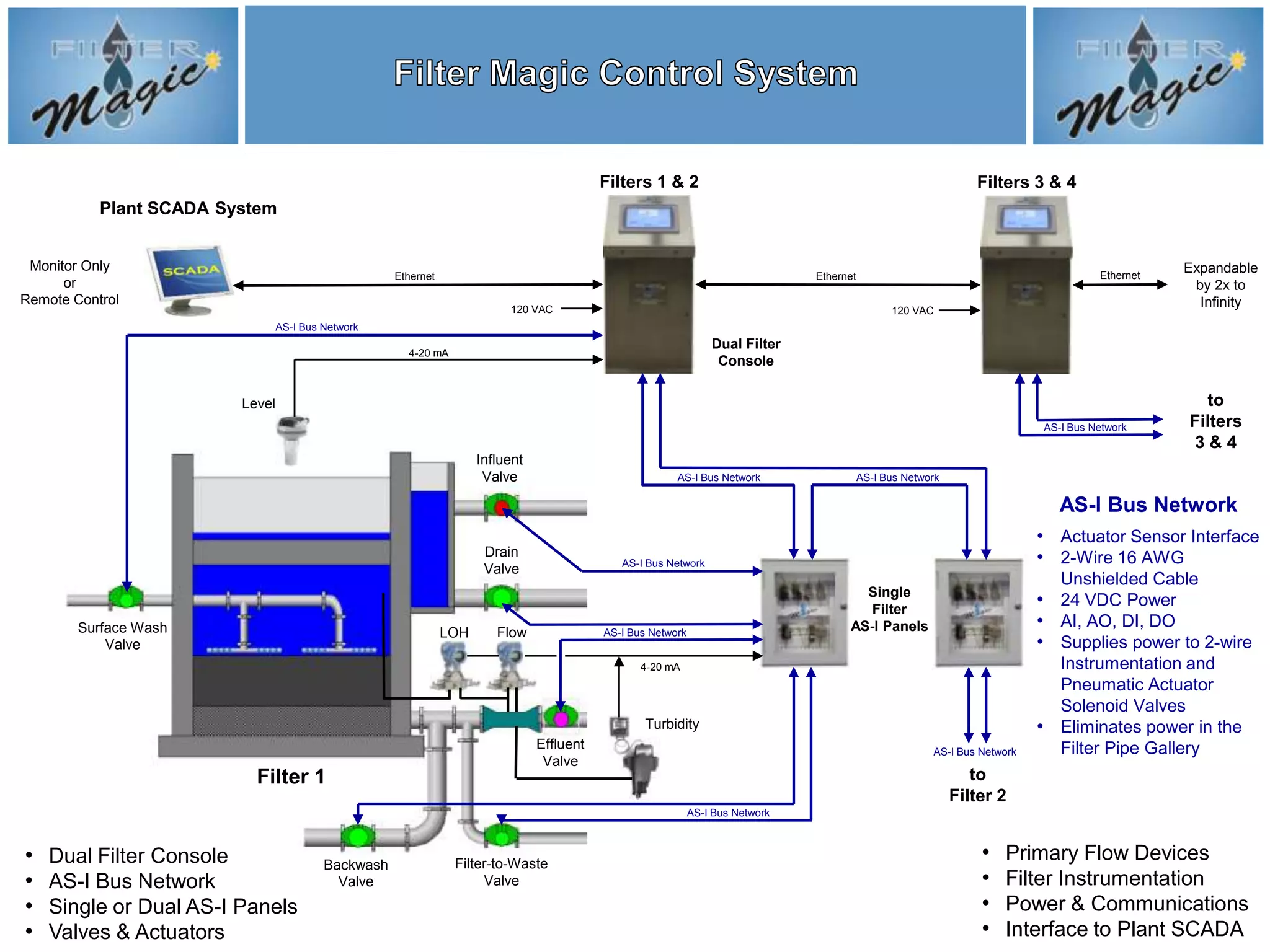

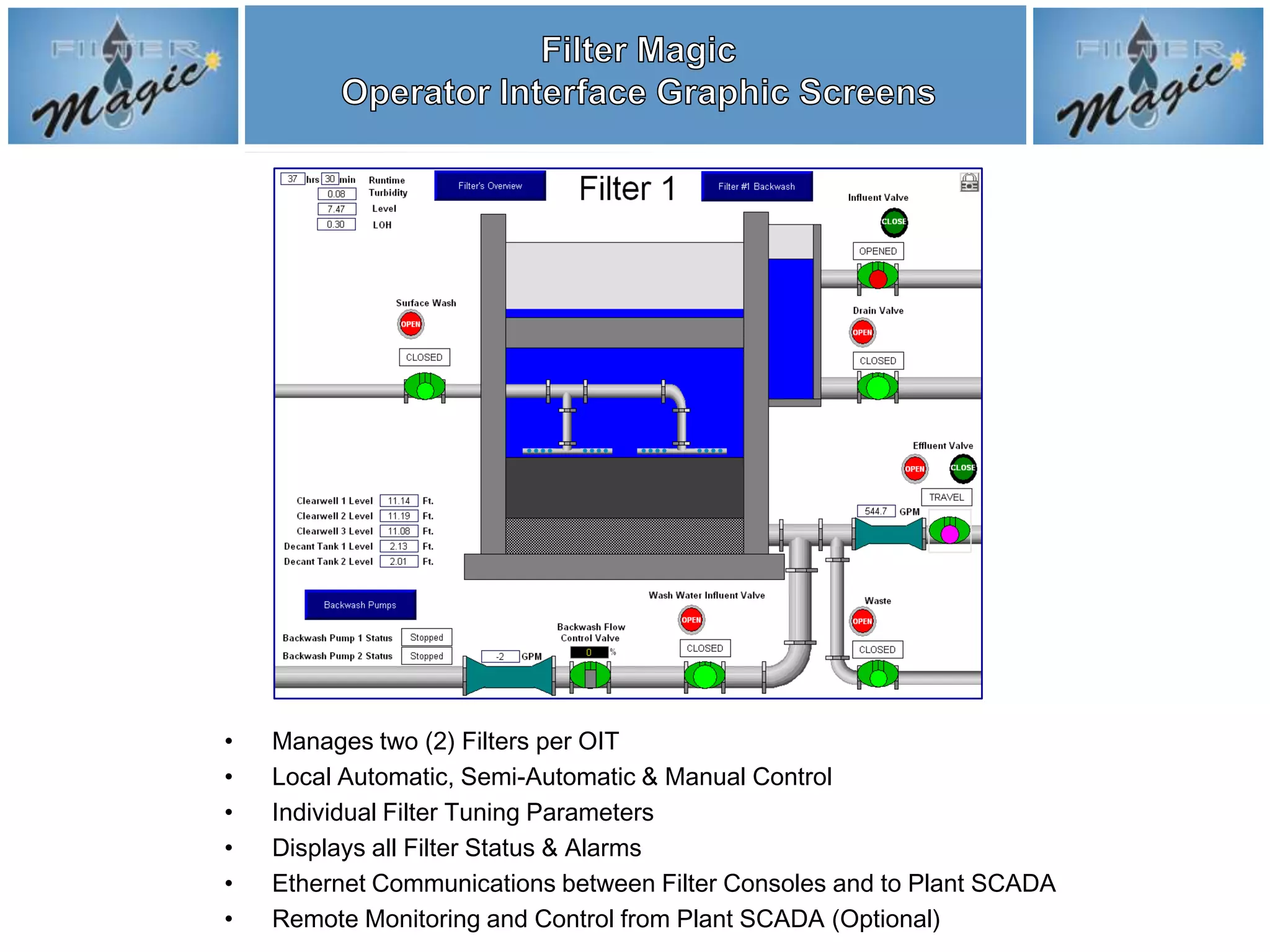

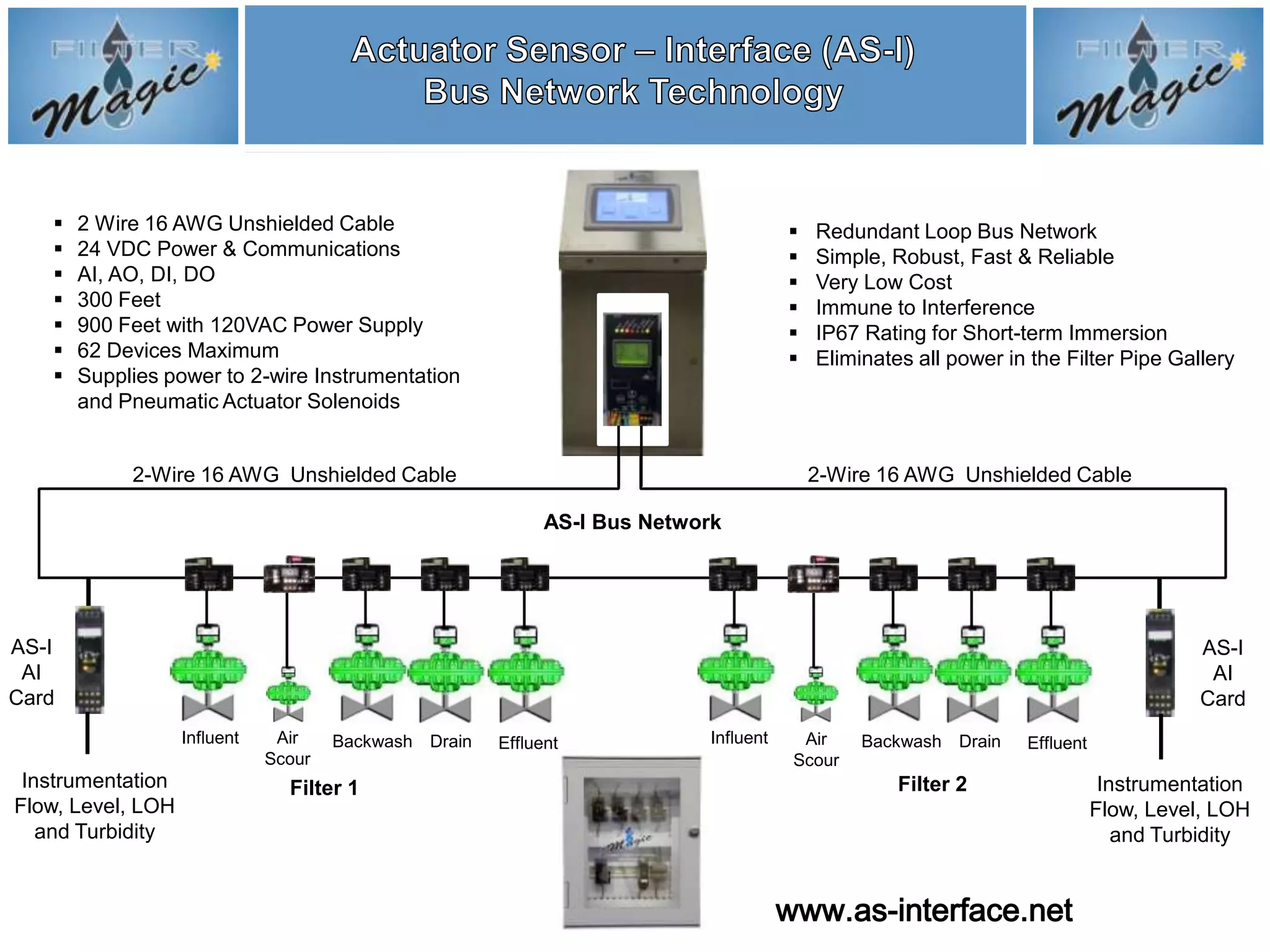

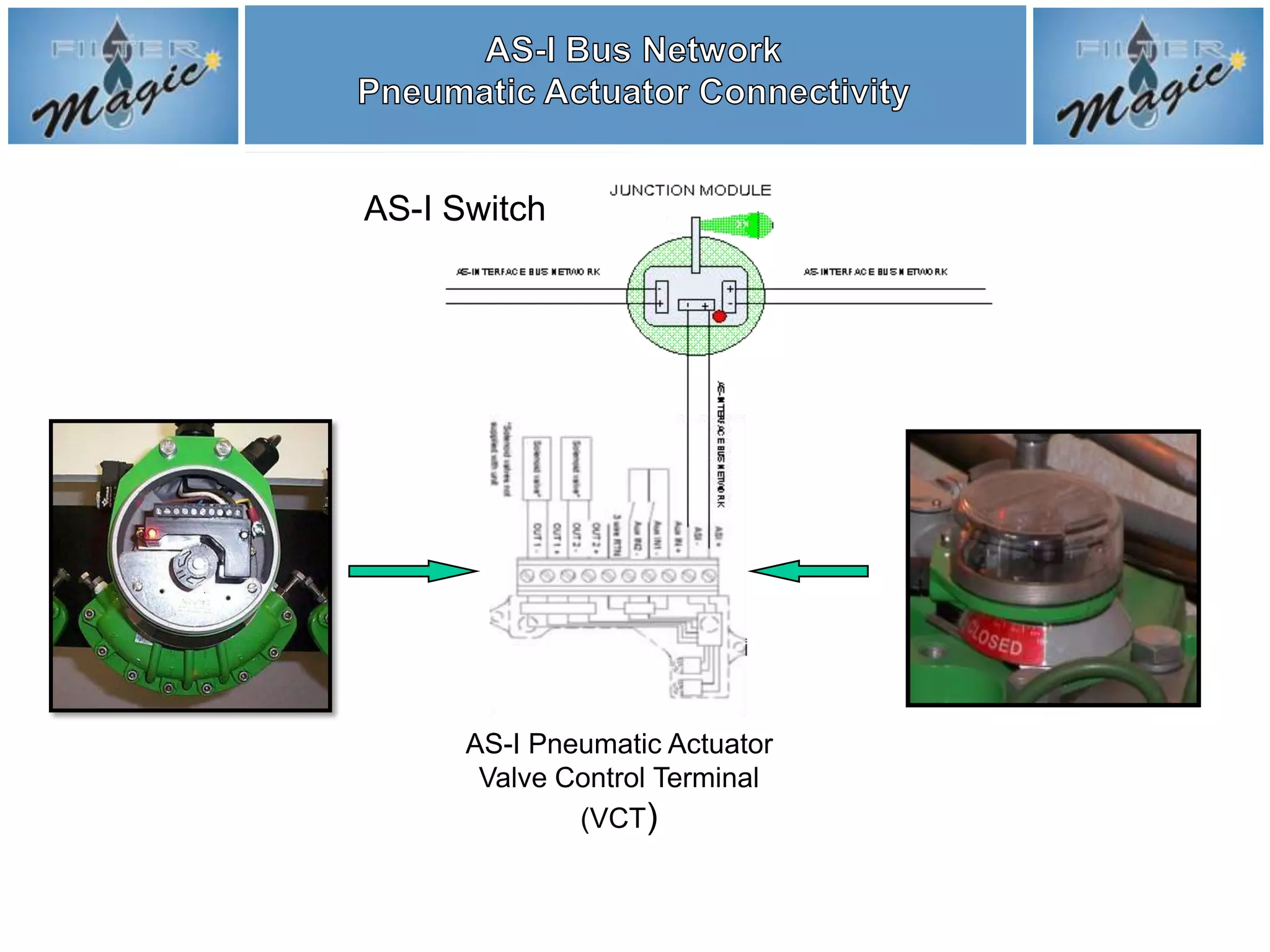

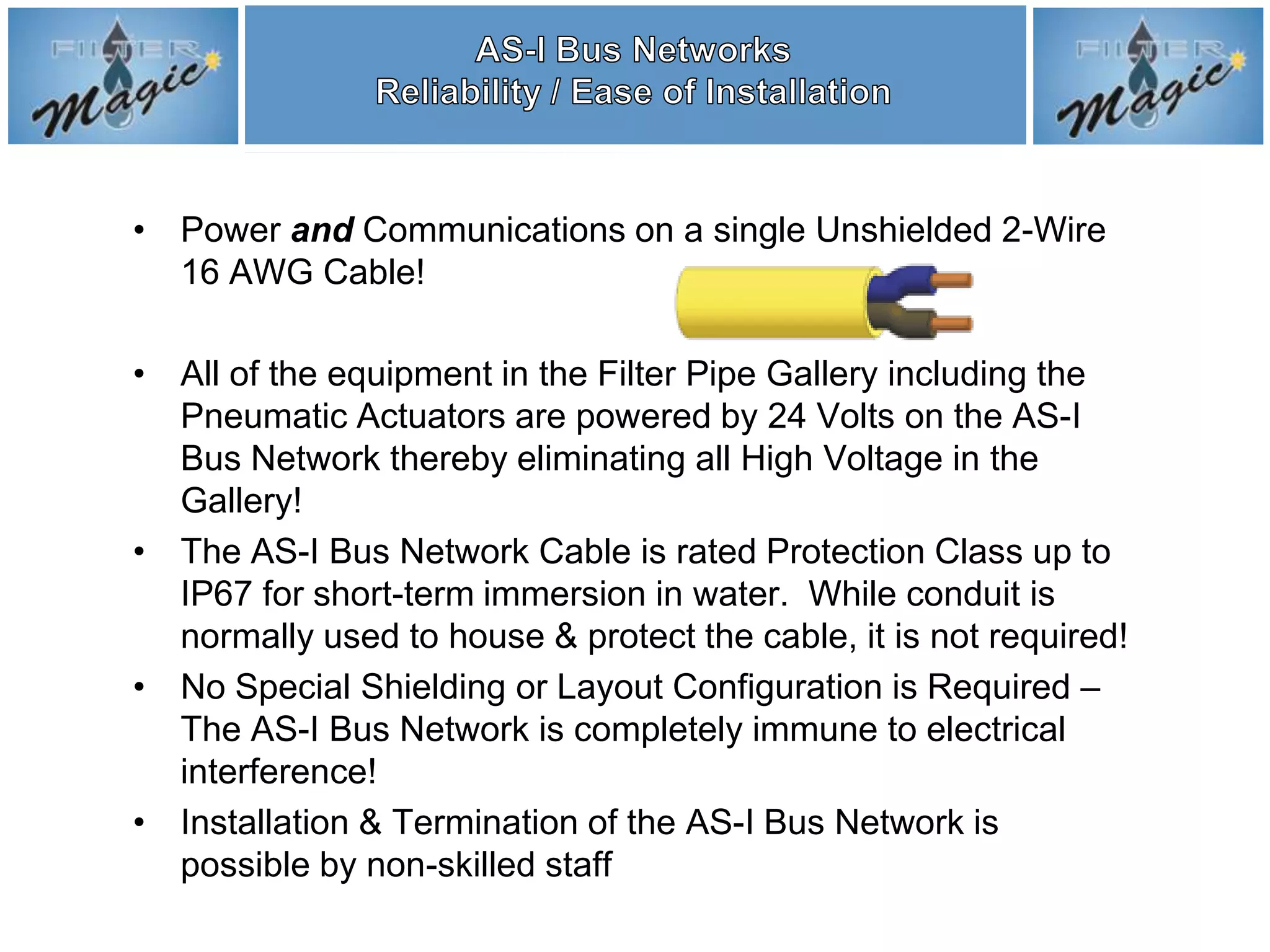

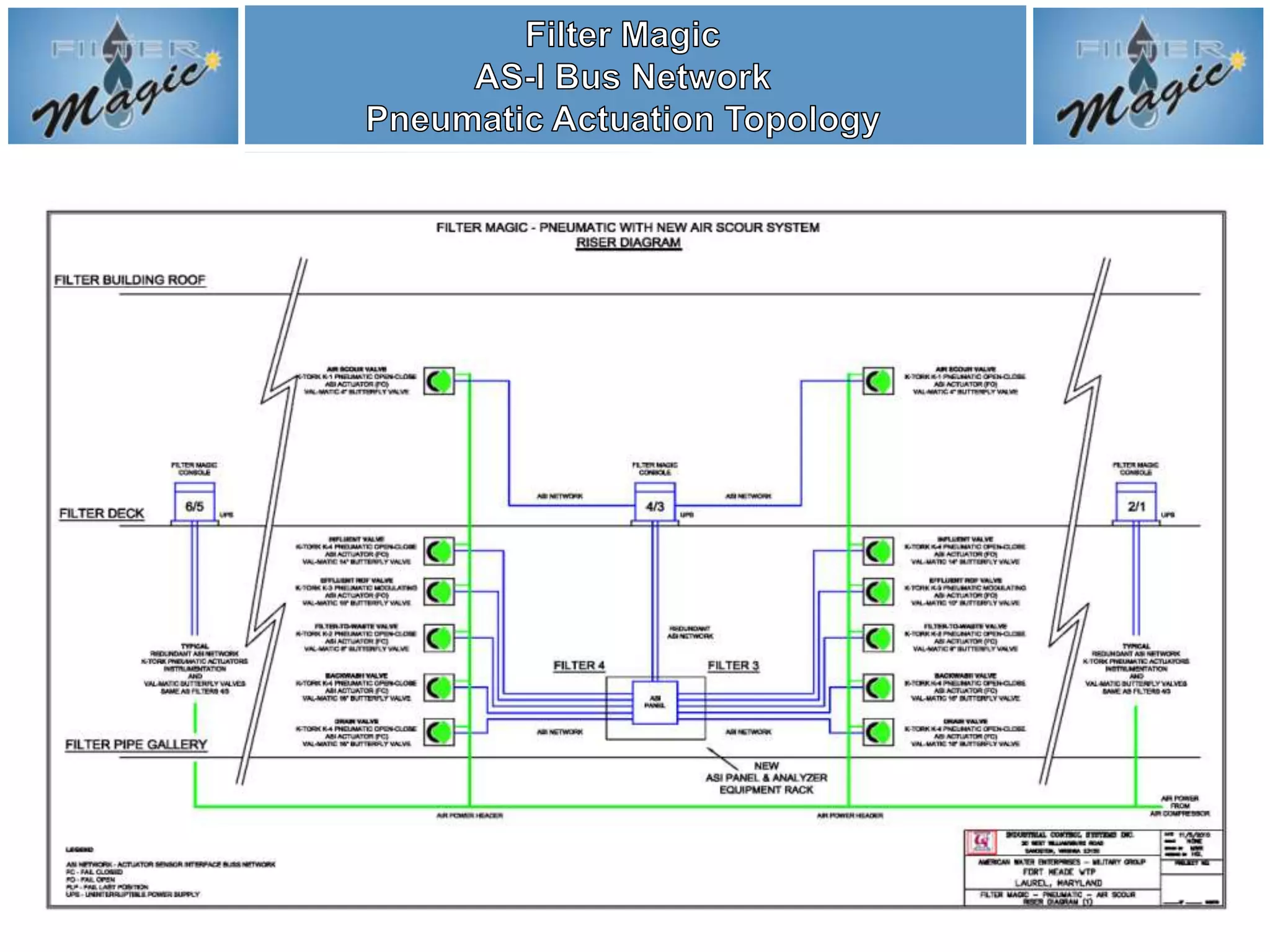

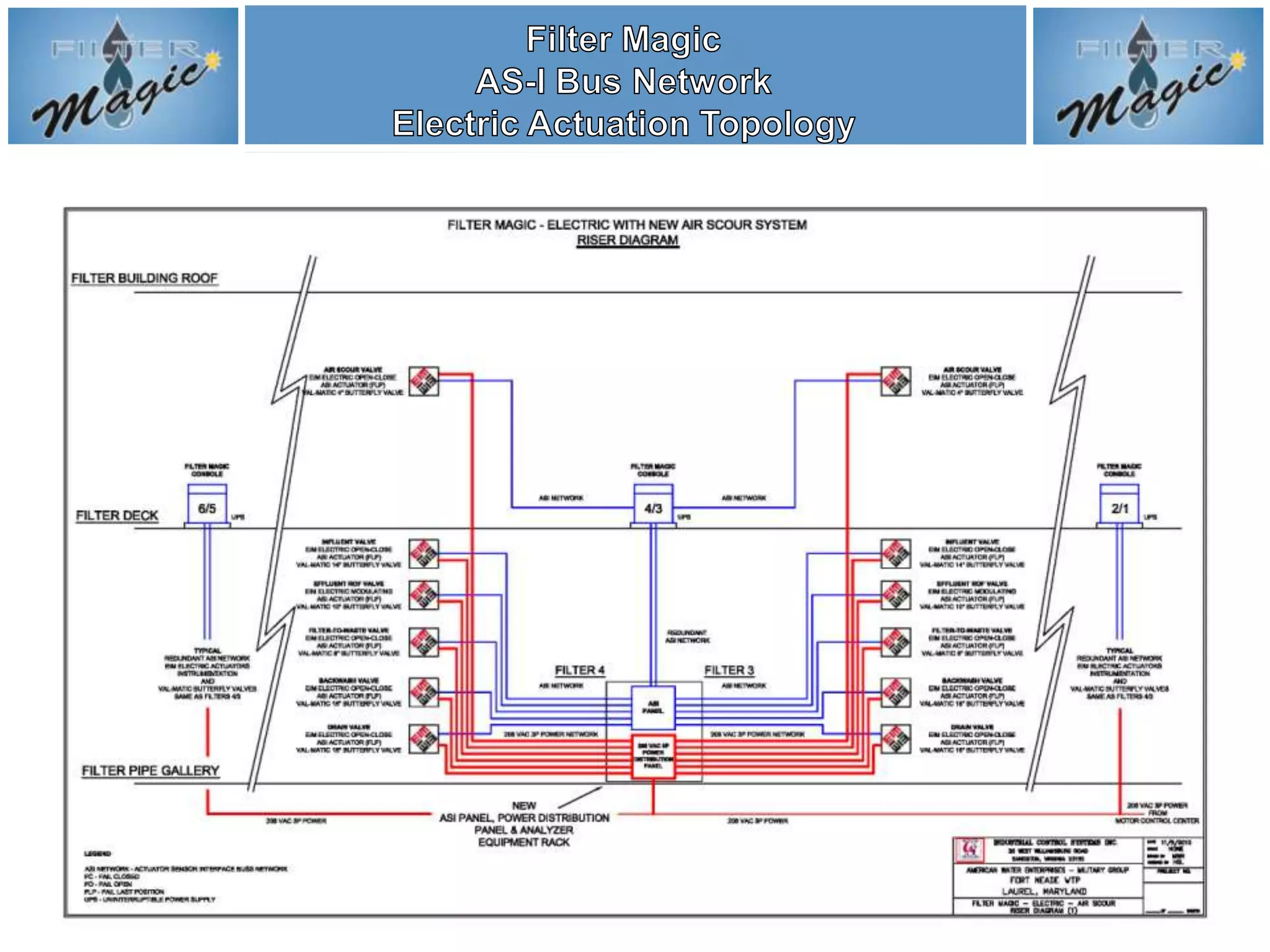

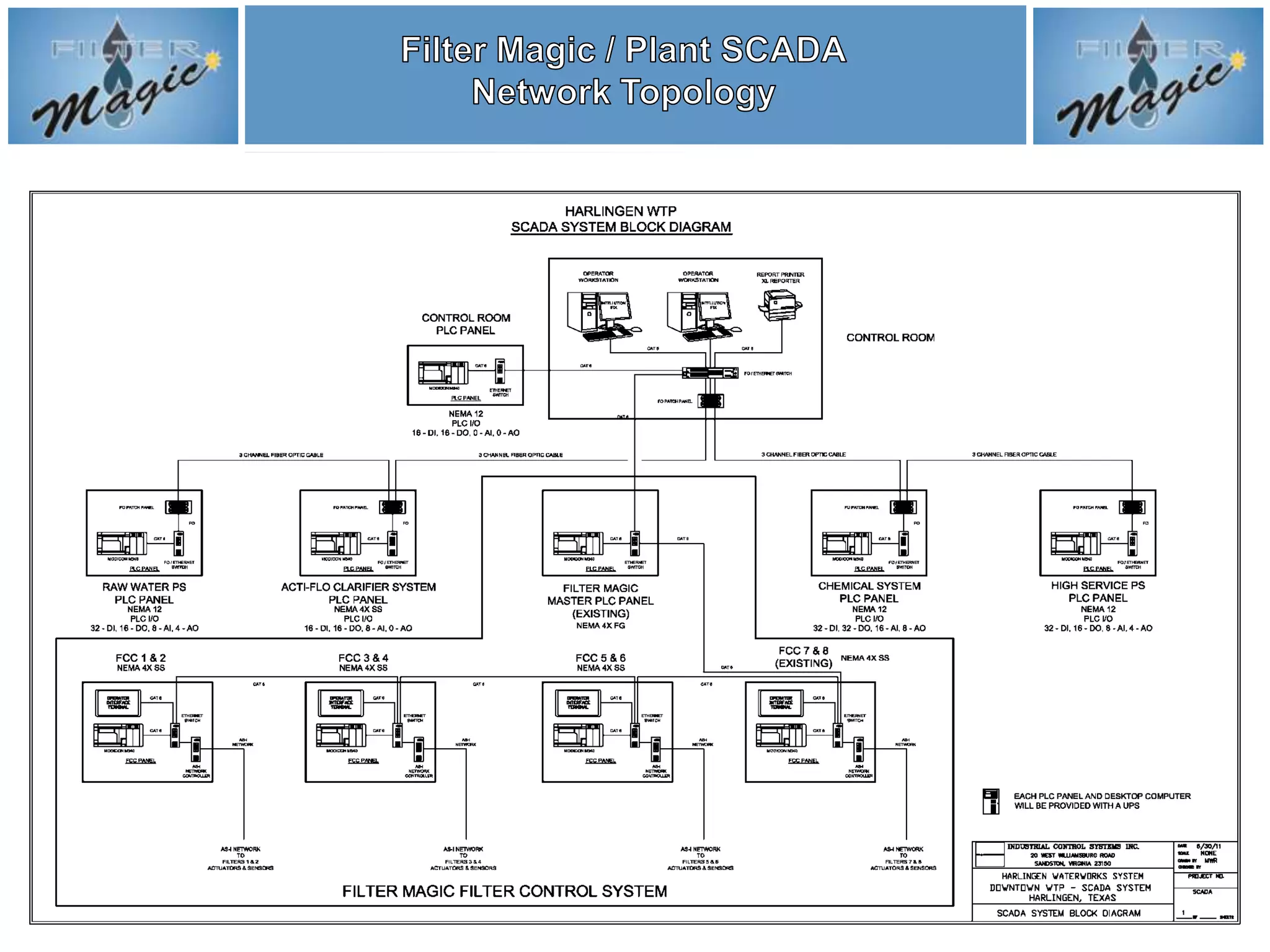

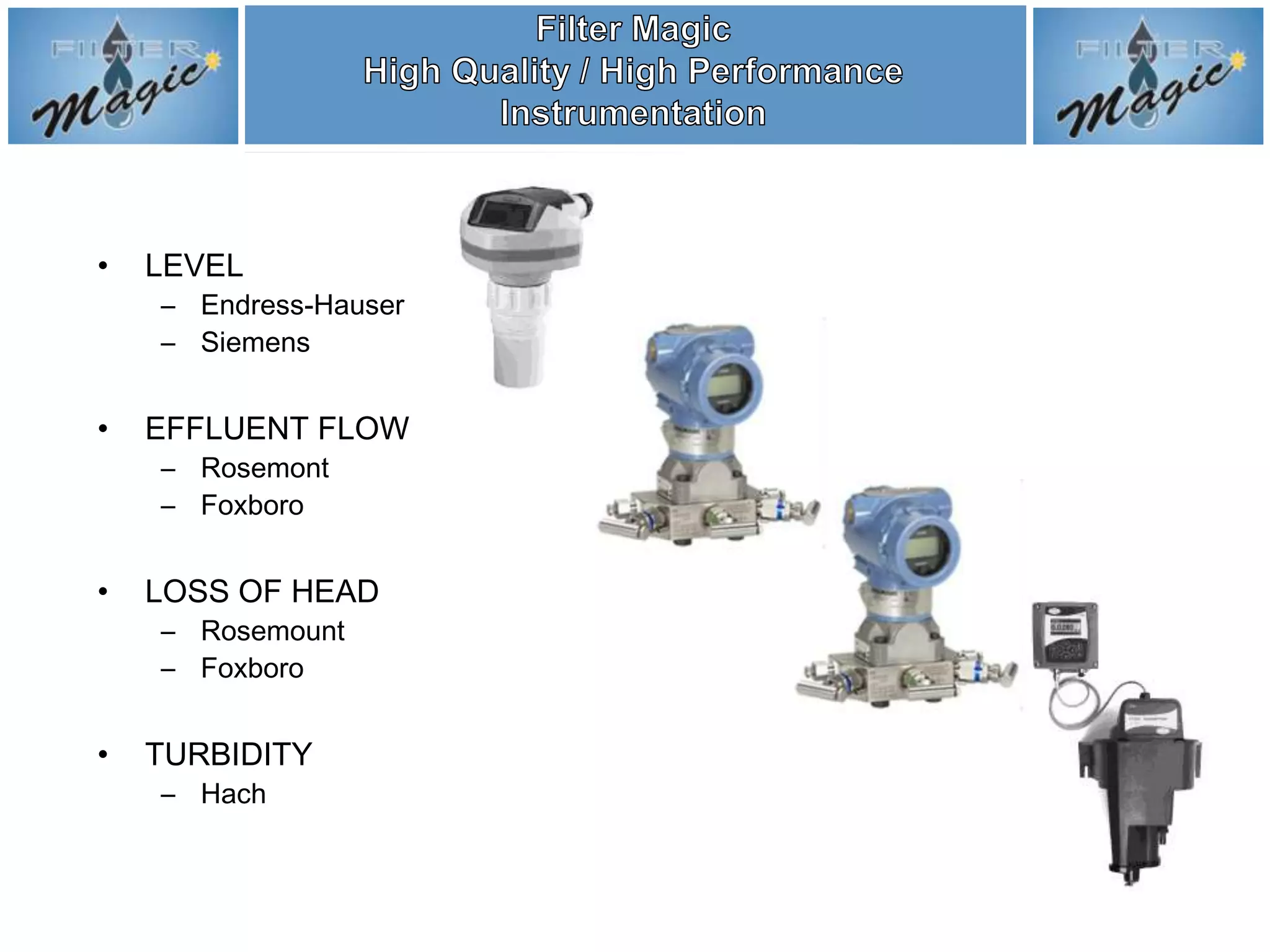

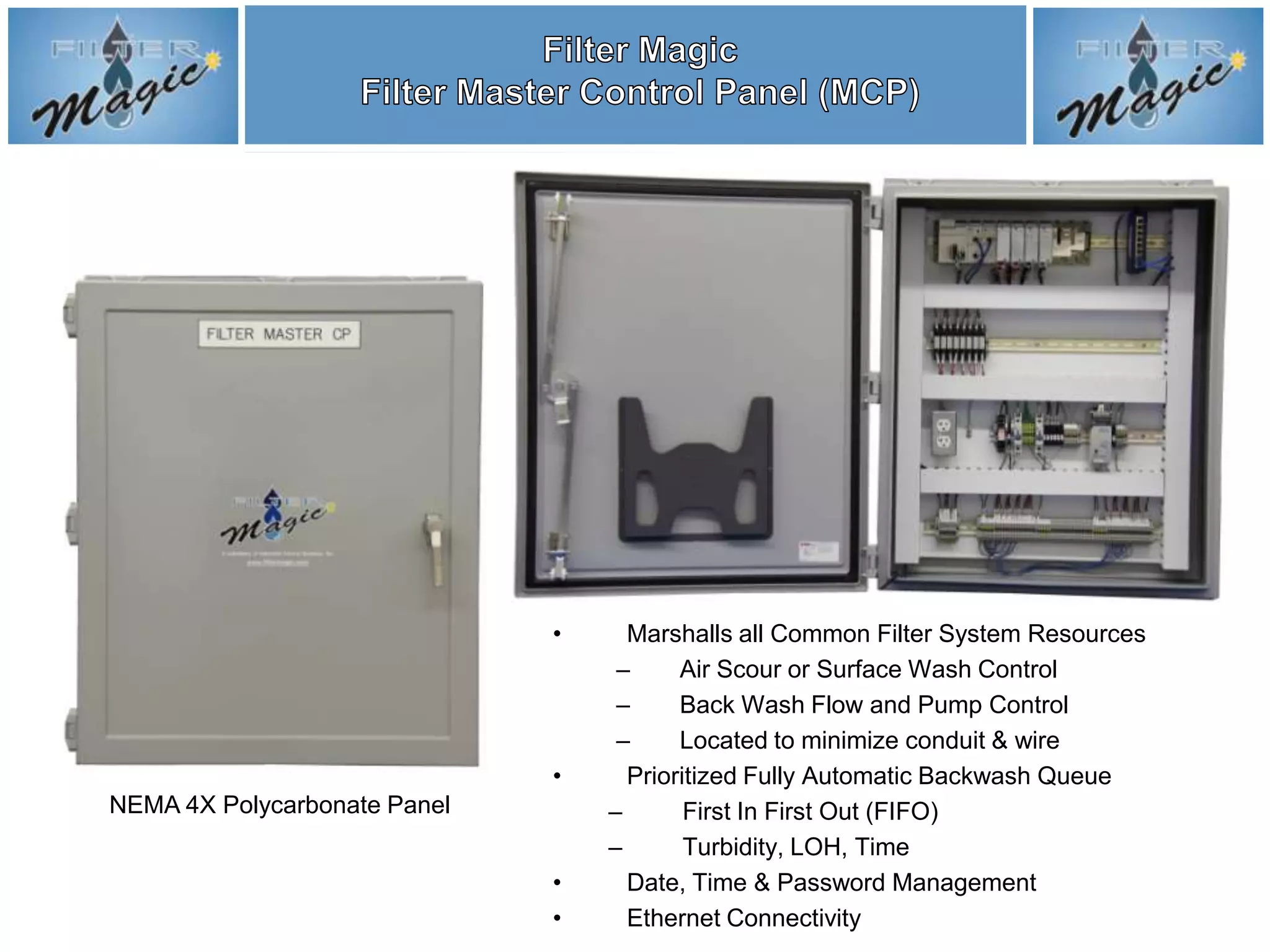

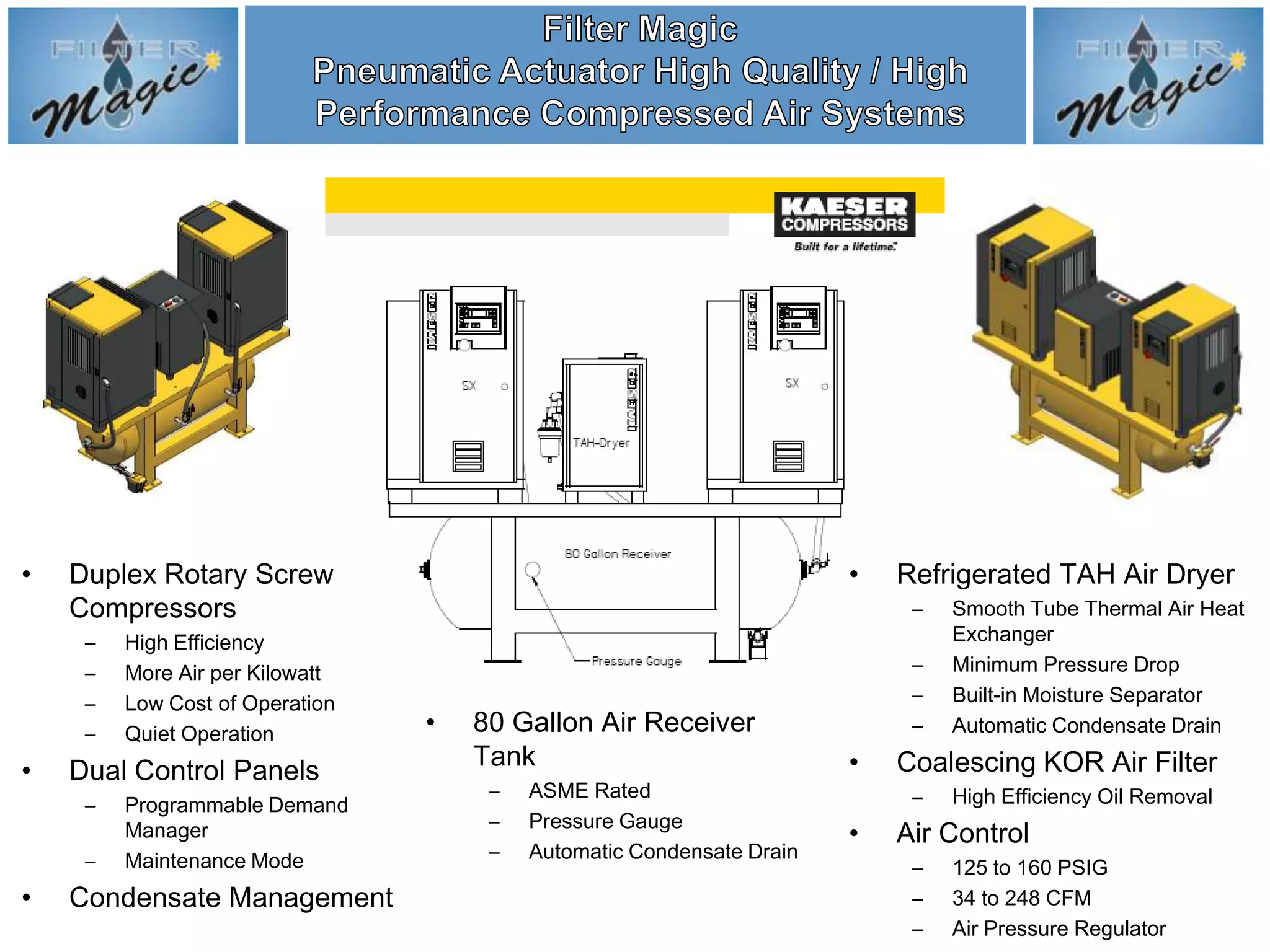

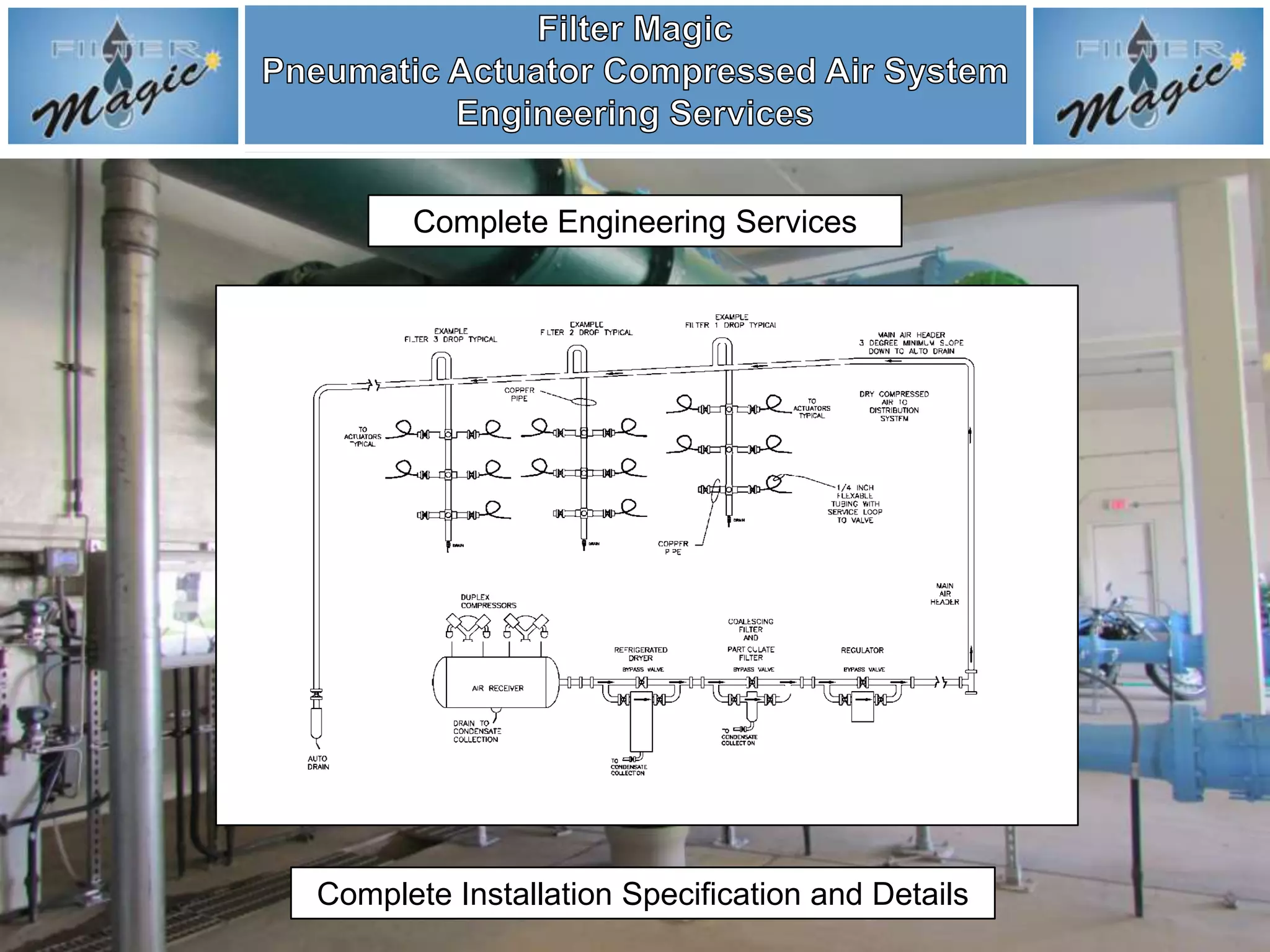

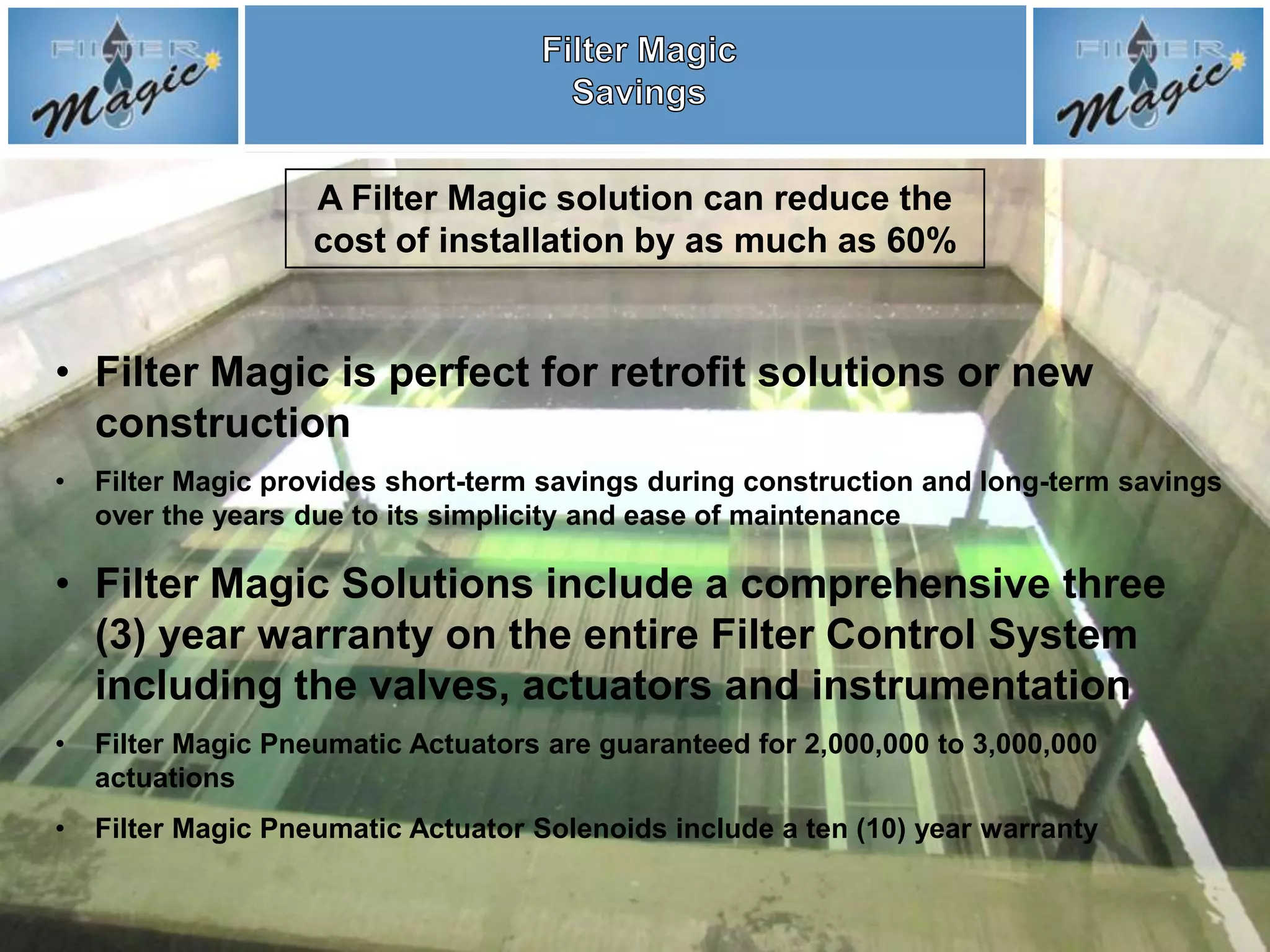

This document presents Filter Magic's green technology for industrial control systems. It offers an exclusive license agreement to manufacture and sell Filter Magic systems throughout the USA. Filter Magic solutions can reduce installation costs by up to 60% and include NEMA rated filter consoles, touch screen interfaces, and AS-I bus networks to connect valves, actuators, and instrumentation. The AS-I network uses two-wire cable for power and communications, is robust and reliable, and eliminates power in filter galleries.