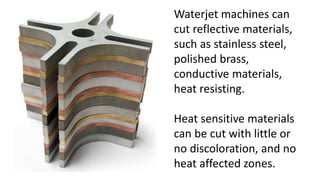

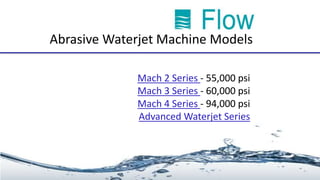

Flow International's Michigan dealer representatives promote VMC Technologies' abrasive waterjet cutting technology, which utilizes high-pressure water and abrasive materials to cut various materials with precision. Waterjet machines can effectively cut reflective and heat-sensitive materials with minimal discoloration, achieving tolerances of +/- 0.001” and depths up to 12” thick. The document also compares waterjet techniques to plasma, laser, and wire EDM machining.