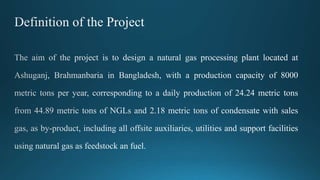

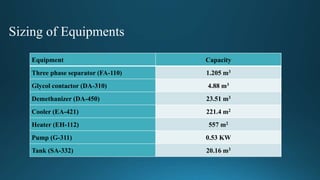

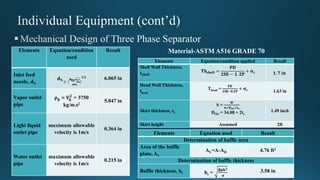

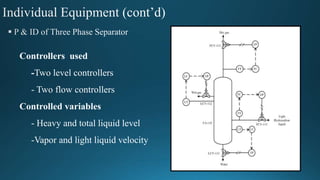

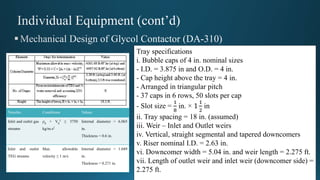

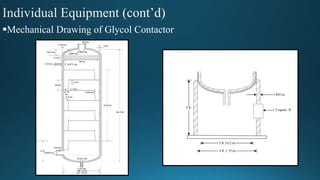

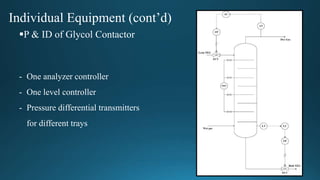

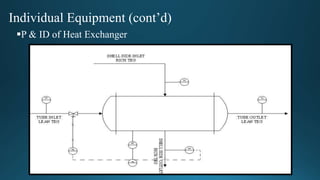

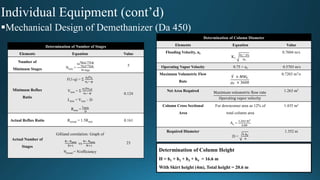

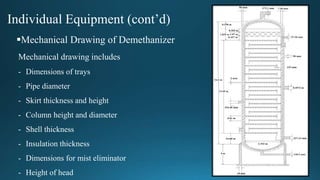

The document provides a detailed analysis of a chemical processing unit, including component mole fractions, equipment specifications, and mechanical designs for separators, heat exchangers, and demethanizers. It outlines economic analysis with capital costs, profit estimates, and feasibility metrics such as internal rate of return. Overall, it offers a comprehensive overview of equipment design and economic viability for the facility's operations.