production of urea Presentation-Group 4.pptx

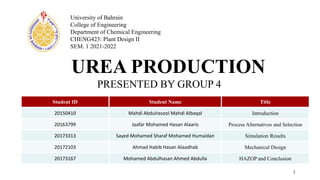

- 1. UREA PRODUCTION PRESENTED BY GROUP 4 1 University of Bahrain College of Engineering Department of Chemical Engineering CHENG423: Plant Design II SEM. 1 2021-2022 Student ID Student Name Title 20150410 Mahdi Abdulrasool Mahdi Albaqal Introduction 20163799 Jaafar Mohamed Hasan Alaaris Process Alternatives and Selection 20173313 Sayed Mohamed Sharaf Mohamed Humaidan Simulation Results 20172103 Ahmad Habib Hasan Alaadhab Mechanical Design 20173167 Mohamed Abdulhasan Ahmed Abdulla HAZOP and Conclusion

- 3. Urea One of the most important nitrogen-based fertilizer 3

- 10. CH2: Process Alternatives and Process Selection 10

- 12. Advantages and Disadvantages Advantages Disadvantages No water in recycle streams The reactor requires delicate control CO2 as stripping agent Slightly less CO2 conversion Tolerates impure feed 12

- 13. ACES Process 13

- 14. Advantages and Disadvantages Advantages Disadvantages Highest CO2 conversion achievable Slightly higher operating temperature and pressure Less energy requirements 14

- 16. CH3 HYSYS Simulation and Results 16

- 17. Fluid Package Selection CPA UNIQUAC Peng Robinson accurate when describing phase equilibria of highly polar and strong association compounds significantly more detailed and sophisticated than any of the other activity models. But It’s not suitable for flash calculations at high pressures. phase equilibria. Calculations at high temperature and pressure. used for the Compression section Used to model the reaction in the Urea Reactor -flash calculations 17

- 20. Urea Reactor 20

- 21. HP Stripper 21

- 26. Results 26

- 28. Reactor Results Comp Fed To Reactor (total) (kmol/h) Left Reactor (kmol/h) NH3 6518.9 4173.83 CO2 1861.64 689.10 H2O 1181.25 2353.78 Urea 0 1172.54 Total Flow (kmol/h) 9561.79 8389.25 T (°𝐶) 124.9 189.4 P (barg) 146.5 146.5 CO2 Conversion 63% 28

- 29. Overall Results • the achieved production rate was around 1936.15 ton/day which is less than the required but is still acceptable with an error of 3.2%. Reactor HP stripper MP & LP decombosers Vacuum Concentrator Wt% of Urea in Simulation 0.33 0.447 0.728 0.96 Wt% of Urea in plant 0.33 0.43 0.71 0.96 %Error 0 3.95 2.535 0 29

- 30. Chapter 4: Designing MP Inerts Washing Tower 30

- 33. Packing Type 33

- 34. Column Height & Diameter Height Diameter 1.8288 m 0.3473 m 34

- 35. Validation of Height 𝐻 = 𝐻𝑜𝐺 ∗ 𝑁𝑜𝐺 𝐻𝑜𝐺 = 𝐻𝐺 + 𝑚𝐺𝑚 𝐿𝑚 ∗ 𝐻𝐿 Height Height of one transfer unit 35

- 37. Effective Interfacial Area of Packing • 𝑎𝑤 𝑎 = 1 − 𝑒𝑥𝑝 −1.45 𝜎𝑐 𝜎𝑙 0.75 𝐿𝑤 𝑎𝜇𝐿 0.1 𝐿𝑤 2𝑎 𝜌𝐿 2𝑔 −0.05 𝐿𝑤 2 𝜌𝐿𝜎𝐿𝑎 0.2 37

- 38. Liquid and Gas Mass Transfer Coefficients 𝐾𝑔𝑅𝑇𝑔 𝑎 𝐷𝑔 = 𝐾5 𝑉 𝑤 𝑎 𝜇𝑔 0.7 𝜇𝑔 𝜌𝑔𝐷𝑔 1 3 𝑎 𝑑𝑝 −2 𝐾𝐿 𝜌𝐿 𝜇𝐿 𝑔 1 3 = 0.0051 𝐿𝑤 𝑎𝑤 𝜇𝐿 2 3 𝜇𝐿 𝜌𝐿 𝐷𝐿 −0.5 𝑎 𝑑𝑝 0.4 Gas-film mass transfer coefficient Liquid-film mass transfer coefficient 38

- 39. Liquid and Gas Transfer Unit Height 𝐻𝐺 = 𝐺𝑚 𝐾𝑔 𝑎𝑤 𝑃 𝐻𝐿 = 𝐿𝑚 𝐾𝐿𝑎𝑤𝐶𝑡 Gas-film transfer unit height Liquid-film transfer unit height 39

- 40. Height of one Transfer unit & Total Height 𝐻𝑜𝐺 = 𝐻𝐺 + 𝑚𝐺𝑚 𝐿𝑚 ∗ 𝐻𝐿 𝐻 = 𝐻𝑜𝐺 × 𝑁𝑜𝐺 40

- 41. Height Validation Calculated Height HYSYS Estimated Height 1.844 m 1.8288 m % Error 1.32 % 41

- 42. Column Efficiency 𝐸𝑜 = 0.377 𝑚 × 𝑀𝐿 × 𝜇𝐿 𝜌𝐿 0.209 𝐸𝑜 = 0.68 H = 1.844 0.68 = 2.71 𝑚 Number of Stages N = 2 0.68 = 2.94 ≈ 3 42

- 43. Mechanical Design Design Temp (min/max) Design Pressure MOC Wall Thickness Closure type Closure Thickness Nozzle Diameter Nozzle Thickness Min=88 °F, Max=190 °F 319 psia 304 stainless steel 3.75 mm Ellipsoidal- only for the top 3.75 mm -6.84mm for Washing Water and Makeup -52.5mm for vent gas 1.73mm for Washing Water and Makeup -3.912mm for Vent gas 43

- 46. Price CERPI @2021 = 701.4 CERPI @2002 = 395.6 Total price= 27,868.06 $ 46

- 47. HAZOP Study 47

- 48. HAZOP Study Summary on the HP Carbamate Preheater Intention: Heat the Carbamate solution to 105 °C at 154 barg and 2800 kmol/h No Guide word Deviation Cause Consequences and Action 1 High High process fluid inlet temperature Disturbances in prior stages Excessive heating – install controllers to manipulate utility fluid flowrate 2 Low Low process fluid inlet temperature Disturbances in prior stages Inadequate Heating – install controllers to manipulate utility fluid flowrate 3 No No Process Fluid Failure of utility inlet valve (close) No heating – install temperature indicators at inlet and outlet, fit an alarm 48

- 49. HAZOP Study Summary on the HP Carbamate Preheater Intention: Heat the Carbamate solution to 105 °C at 154 barg and 2800 kmol/h No Guide word Deviation Cause Consequences and Action 4 More More Process Fluid Failure of utility inlet valve (open) Excessive heating – install temperature indicators at inlet and outlet, fit an alarm 5 Less Less Process Fluid Leakage or blockage Inadequate heating - install temperature indicators at inlet and outlet, fit an alarm 6 Reverse Reverse process fluid flow Failure of process fluid inlet valve Product off set – install NRV 49

- 50. HAZOP Study Summary on the HP Carbamate Preheater Intention: Heat the Carbamate solution to 105 °C at 154 barg and 2800 kmol/h No Guide word Deviation Cause Consequences and Action 7 Corrosion Corrosion of tubes Fouling of utility fluid Inadequate heating and cracking – periodic maintenance 8 Contamination Process fluid contamination Pipe cracking causing utility fluid mixing with process fluid Inadequate heating – periodic maintenance 50

- 52. Study, analyze and compare possible alternatives The 3 alternatives are Snamprogetti process, Stamicarbon process and ACES process process. The suggested alternative is Snamprogetti process 52

- 53. Simulating the process in Aspen HYSYS V11 • The simulation required the application of 3 fluid packages • A production rate of 2000 ton/day was achieved with 3.2% error (1936.15 ton/day) of Urea with a purity of 96%wt 53

- 54. Design of MP Inerts Washing Tower • The design was achieved through the help of Aspen HYSYS, hand calculations and sound judgment. • The material of construction was determined based on the relative cost and resistivity to rusting and corrosion. • The diameter was obtained through HYSYS based on the chosen packing type and sizes. • The length was determined through HYSYS and through manual calculations in conjunction with the column efficiency to determine actual height. • The column closures were chosen based on the design pressure • The nozzles were sized using the HYSYS line designer, and their materials of construction matched the vessel they are attached to. 54

Editor's Notes

- sdsds