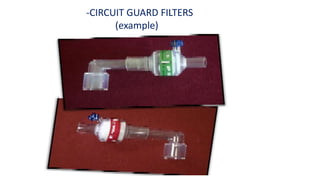

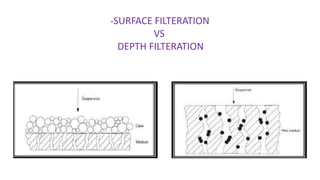

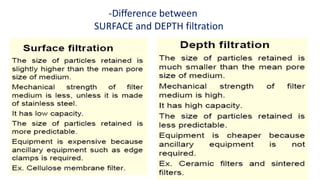

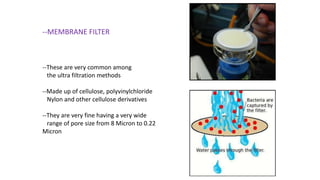

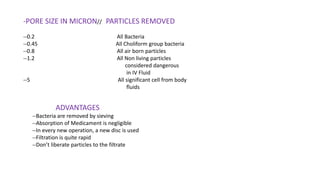

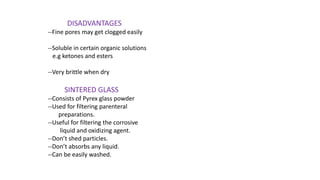

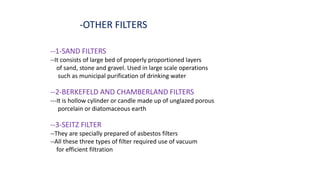

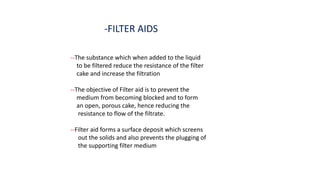

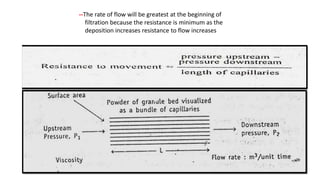

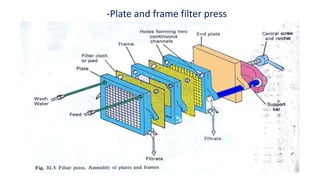

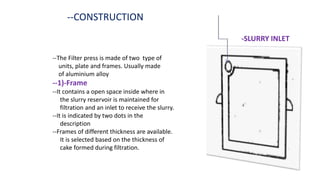

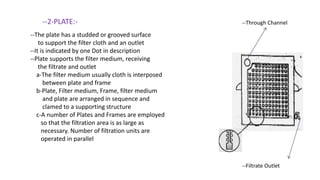

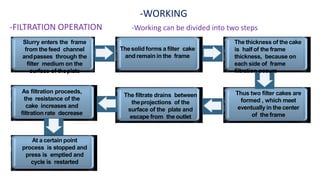

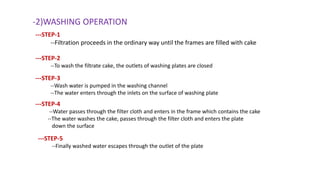

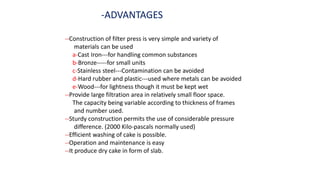

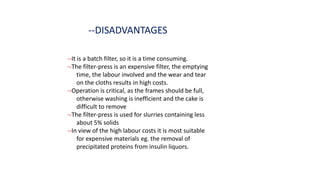

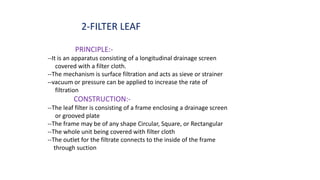

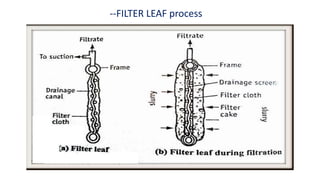

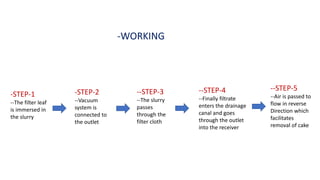

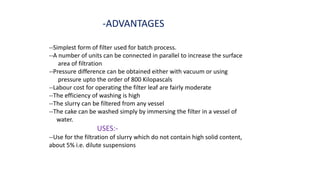

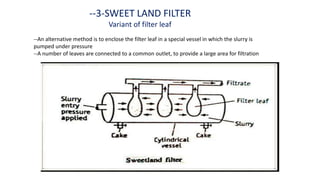

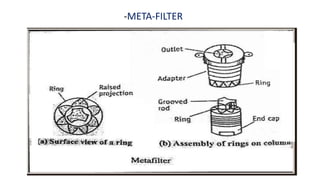

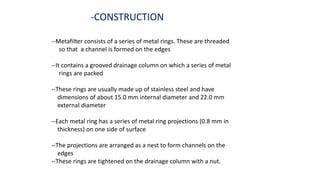

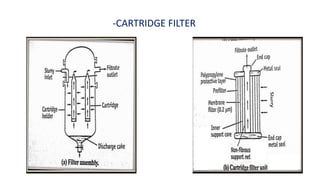

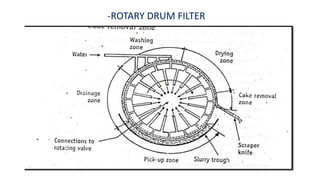

This document discusses various types of filtration equipment and processes. It describes filtration, clarification, and some basic terminology related to filtration. It then covers different types of filtration like surface and depth filtration. Various factors affecting the rate of filtration are discussed. Different mechanisms of filtration like straining, impingement, and entanglement are described. The document also discusses filter media, materials used as filter media, and selection of filter media. Finally, it provides details on various industrial filters used in pharmaceutical industries like filter presses, filter leaves, rotary filters, and membrane filters.