Instrument Supervisor CV Summary

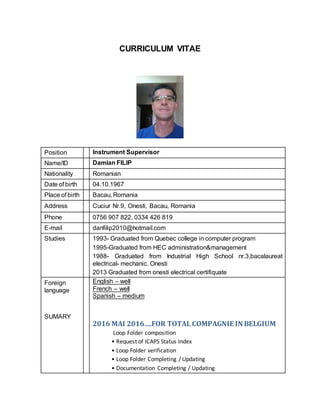

- 1. CURRICULUM VITAE Position Instrument Supervisor Name/ID Damian FILIP Nationality Romanian Date of birth 04.10.1967 Place of birth Bacau, Romania Address Cuciur Nr.9, Onesti, Bacau, Romania Phone 0756 907 822, 0334 426 819 E-mail danfilip2010@hotmail.com Studies 1993- Graduated from Quebec college in computer program 1995-Graduated from HEC administration&management 1988- Graduated from Industrial High School nr.3,bacalaureat electrical- mechanic. Onesti 2013 Graduated from onesti electrical certifiquate Foreign language SUMARY English – well French – well Spanish – medium 2016 MAI 2016….FOR TOTAL COMPAGNIE IN BELGIUM Loop Folder composition • Request of ICAPS Status Index • Loop Folder verification • Loop Folder Completing / Updating • Documentation Completing / Updating

- 2. • OPV Form (under Company Template) • Complex Loop Form : procedure / Folder / Sheets Work Permit issuance • Loop Test • Complex Loop Test completion DCS • Functional Test completion ESD / F&G • Operational Test (OTP) assistance • Removal / Reinstatement of instruments to support some other Contractors activities • Punching • Documentation Mark-Up 2016 MARCH -2016 1MAY AXAY KAZASTAN FOR SHOUTDOWN CHANGE COMPRESOR MCH5TOMCH 6 PREPEARTHE CONECTION FORTHE MARSHALINGCABINETALLTHE CONECTION WHIR THE NEW INSTRUMENT OF NEW INSTALIATION CHECK LOOP 2015-Julay-2015 November Shetland Scotland E&I Supervisor in construction, pre-commissioning, commissioning, activities for electrical, low and medium voltage equipment, calibrating and loop-checking, installations, starting and maintenance activities for field and control room in oil refinery and chemical - 25 years’ experience.. 2015- 2015 SHETLAND ISLAND TOTAL the project (SGP) plant Laggan-Tormore Comissioning analyzer metering whit vendor for the client TOTAL verification calibratation and maintenance like Spectra, ABB,CROMATOGRAFKHRONE , ROSEMONT, EMERSON,allredy for the START UP, and flow transmitter , tt , pt, mov. Valve bifi .All the commissioning for the instrumentation fix up all the problem and the installation to be made the standart EU. Loop- checks, pressure test,wire to wier ,make sure each test is perform conform the regulation and the standard ask it singed up the paper after test and control quality.

- 3. Experience 2013-2015,AGIP, Karabatan Refinery, Kazakhstan Position: EIT Supervisor and compressor BentlyNevada ,Voiht VORECON Tasks: Test ESD for all the instrument whit the plant operational and inspect the instrument Training for H2S level 1 and level 2 by OPITO COMPANYIN ATYRAU Planning required up gradationfor instruments to achieve production quality and cost minimizing. Instrument Supervaiser position. Must be able to calibrate, test and install pressure, level, temperature, and flow instruments; pneumatic and electronic. Experience with solenoid actuated valves. Have a good knowledge of process control. Trouble shooting, and familiar with Programmable Logic Controllers Proficient in running tubing. Experience inthe Oil and Gas and refiner. Maintenance and calibration of pneumatic control valves ( Weir, Flowserv, Black borough,..... ) and part turn actuated valves ( Bray, Airtorque, Flowtek,..... ); Maintenance and calibration of different analyzers : Conductivity, Chlorine, PH, SDI, Redox, Turbidity, TDS ( Endress and Hauser ) and IMA/FL200 Oil in water; Maintenance and calibration of flow meters ( electromagnetic, orifice plate, variable area, turbine, ultrasonic..... ) of ABB, Krohne, Rosemount, +GF+, Polysonics;Maintenance and calibration of transmitters PT, LT, TT, DPT(EmersonRosemount, Endress& Hauser, ABB ,.....) and Monitranvibrationtransducers. Calibrating and adjusting the dosing pumps (Prominent);Cathodic protection testing for five 10,000 m3 reservation tanks; Ensure Spares balance and inventory control for all instruments’ spare parts; Planning required up gradation for instruments to achieve production quality and cost minimizing. Maintenance and calibration of pneumatic control valves ( Weir, Flowserv, Blackborough,..... ) and part turn actuated valves ( Bray, Airtorque, Flowtek,..... ); Maintenance and calibration of different analyzers : Conductivity, Chlorine, PH, SDI, Redox, Turbidity, TDS ( Endress and Hauser ) and IMA/FL200 Oil in water; Maintenance and calibrationof flow meters ( electromagnetic, orifice plate, variable area, turbine, ultrasonic..... ) of ABB, Krohne, Rosemount, +GF+, Polysonics; Maintenance and calibration of transmitters PT, LT, TT, DPT (Emerson Rosemount, Endress& Hauser, ABB ,.....) and Monitran vibration transducers. Calibrating and adjusting the dosing pumps (Prominent;) Cathodic protection testing for five 10,000 m3 reservation tanks; Ensure Spares balance and inventory control for all instruments’ spare parts. 2013,Chevron, Baku, Azerbaijan Position: Instrument Supervisor Tasks: Perform checklist with assistance off instrument assistant.Check preparation of loop folders for each loop test with

- 4. instrument assistant, in due time prior to loop test. After receipt of loop test folders from Instrument Coordinator, ask instrument assistant to perform loop test. Supervise field loop checks.Check preparation of loop folders for each loop test with instrument assistant, in due time prior to loop test. After receipt of loop test folders from Instrument Coordinator, ask instrument assistant to perform loop test.Supervise repair of loops with instrument assistant & inform readiness of loop to Instrument coordinator.During Commissioning if some carry out troubleshooting.Oversee the works of vendors and ensure efficient utilization of vendor m VERFY and check failure system testing statistical control checkup wartime production and the control the quality production and we do (fit purpose) all the pieces to be the right one and (right first time ) the mistake to be eliminated. All the measurement to be comparison whit the standard measure. Do inspection (QC) to verify the pieces to have a good condition not to have a crack and to test it to see if is working in a standard condition. Accomplished work to ensure its alignment whit the project scope. Test the system and calibrating the system to work safety and have a good quality production and to prevent the problem and re-evaluation of the specification on the product. Perform Checklist with assistance off instrument assistant.Check preparation of loop folders for each loop test with instrument assistant, in due time prior to loop test. After receipt of loop test folders from Instrument Coordinator, ask instrument assistant to perform loop test.Supervise field loop checks.Assure that all components in the loop meet specification & calibration requirement.Verify right operation of loop including fail-safe valve actions.Verify the correct interventions off alarms.Verify action of Interlocks & supervise simulation operations on the Instruments.Incas loop is not functioning properly, immediately inform to instrument coordinator.Supervise repair of loops withinstrument assistant & inform readiness of loop to Instrument coordinator.During Commissioning if some carry out troubleshooting.Oversee the works of vendors and ensure efficient utilization of vendor. Maintenance for electrical & instrumentation cabinets for generators, static excitation (PLC controlled) inverters, rectifiers.Project monitoring and site supervision;Technical assistance on site;Coordinating electrical maintenance work with operations divisions;Planning and progress reports. Installation and repair HVAC and calibration of the instrument. 2011 – 2012,Exxon, Lagos, Nigeria Position: Instrument Technician Tasks: Firefighting building; HVAC system; Deluge system Fire & Gas alarm system; Installation and electrical connection of different type of instrumentation such as transmitters, switches, level gauges etc.; Installation of linear heat detector above pipes; Marshaling cabinet wiring.

- 5. 1992 – 2011,Nexen Inc., North Quebec and West Penetone Montreal, Canada Position: Commissioning EITSupervisor Tasks: Firefighting building; HVAC system; Deluge system Fire & Gas alarm system; Installation and electrical connection of different type of instrumentation such as transmitters, switches, leave gauges etc.; Installation of linear heat detector above pipes; Marshaling cabinet wiring; Commissioning for system, control of commissioning documentation acceptance of work; Worked with components in electrical panels LV/MV; Experience in performing tests; Checked tightening bolts in transformer; Made mechanical test and interlocks checked; Measured resistance of main circuit continuity and insulation; Made test on panel Dielectric LV/MV; Digital instruments Shimaden (Controllers and Recorders); Digital instruments Honeywell; Digital instruments Yokogawa; Working whit: potentiometers, pressure measurements, temperatures analyzers, flow meters, flows; Worked with electronic machine and pneumatic apparatus (Hocuschins, Carlo- Erba, Taylor, ABB etc); Executed montage activities at control panel in new installation technologically assigned the installation starting of hydro-straight-run gasoline; Testing and calibrating, to established standards, equipment such as pressure and temperature transmitters, valve positioners, pneumatic controller, electronic controllers, pressure and temperature switches and other process control equipment; Installing, adjusting, inspecting, servicing and repairs a variety of mechanical equipment and mechanical parts of electrical machinery utilized in a power station including vertical and horizontal hydro- electric and thermal generation equipment. Marking repairs on high pressures vessels, such as boiler tubes, hand holes, drums, steam lines, fire boxes, nose casting and expansion joints; Developed, implemented and maintained an effective program of equipment and outage maintenance work, performed equipment inspections to ensures that equipment is safely maintained and operable, performed related testing and repairs as needed. Installed, tested, maintained and repaired high voltage generators, motors, actuators equipment, turbine controls, station auxiliaries, light and control measuring devices. Provided direct oversights and on the job training to apprentices. Coordinated whit others crafts on logistics of assigned project. Assured availability of parts and supplies, by assessing jobs and determining parts needed for job. 1990 – 1992,RAFO Refinery, Romania Position:Maintenance instrumentation foremanTechnician Tasks:Atmospheric and vacuum distillation; Naphtha hydro treating unit; Gas oil hydro treating unit; gases fraction, Merox unit and ethers units; Aromatic extraction unit; Reparation pomp with small and big

- 6. debit (keep the installation on the standard pressure); Working and study blue prints to see what kind of pipe are needed and the exact place to be mounted to. Performing repairs for gas and oil installation into the company, building up a new installation, fix up a rea for pomp and install on the floor fix it up and ready to use. Developed implemented and maintained an effective program of equipment an outage, maintained work performed inspection and ensure the equipment is safely maintained and operable. Installed the following equipment: Honeywell, Masoneilan, Taylor, Rosemont, Fisher, Hartman, Brown, and Foxboro license; participating to commissioning activities of this equipment. Checking instrumentation and control equipment both in the field and in control panel. Troubleshoot repair and perform maintenance on test apparatus and peripheral equipment. Working with electronic apparatus and pneumatic machine, executed montage activities at control panel in new technologically assisting, installing adjusting servicing and repairing a variety of equipment and mechanical parts. 1987 – 1990, Petrochemical Plant Borzesti, Romania Position: Instrument Technician Tasks:Atmospheric and vacuum distillation unit; automation of steam boiler; Automation of thermic plants; automation of chemical reactors; Automation of compressors; Executed reparation for pomp with small or big debit and keep line on the same pressure. Mechanic for general reparation for all devices in the factory automation lines and maintenance the installationto work in standard norm. Maintaining best value for all installations to work well prevent the maintenance inspected and tested all installations to prevent problem and changed broken parts with new ones.