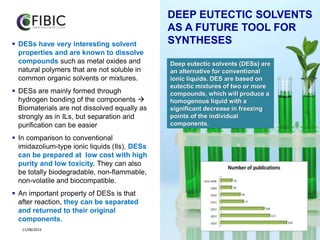

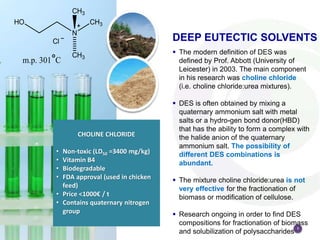

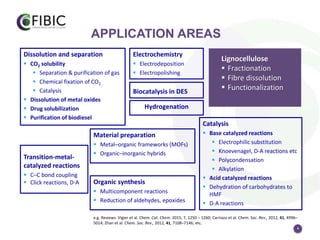

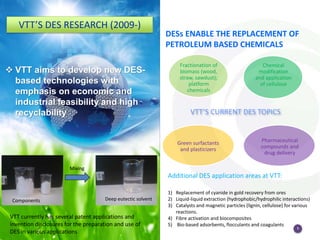

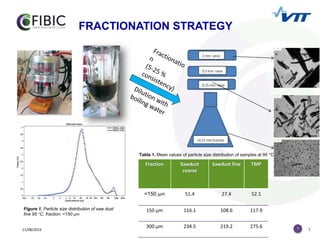

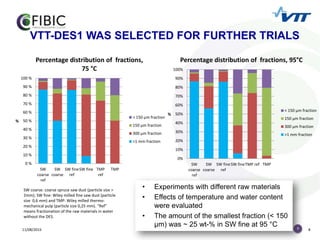

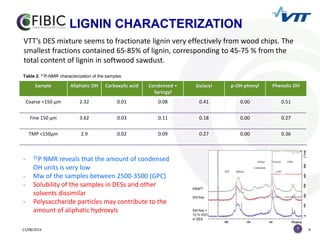

The document discusses the properties and potential applications of deep eutectic solvents (DES) in biomass activation, emphasizing their low cost, biodegradability, and ability to facilitate the separation and recycling of components. It highlights ongoing research at VTT focused on finding effective DES compositions for biomass fractionation and the solubilization of polysaccharides, demonstrating promising results in lignin extraction and cellulose modification. Additionally, several application areas for DES in various chemical processes are outlined, indicating their viability as an alternative to conventional solvents.