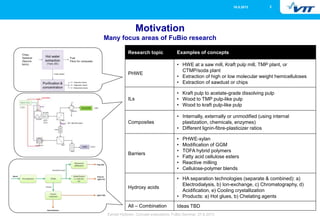

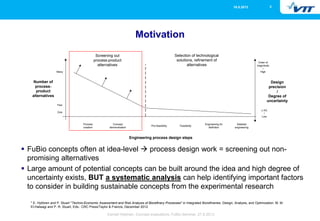

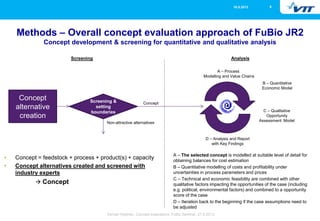

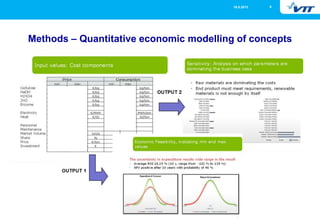

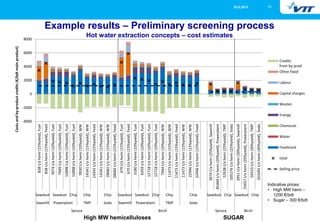

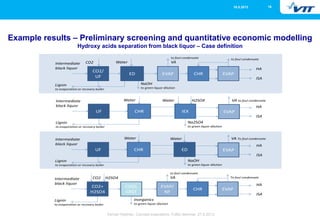

The document summarizes the concept evaluation approach used by the FuBio research program to analyze new process ideas and concepts. It involves preliminary screening of concepts using light techno-economic analysis to generate cost estimates and compare concepts. Promising concepts are then modeled more quantitatively using process modeling and economic analysis. Example results are presented for preliminary screening of hot water extraction concepts and ionic liquid fractionation methods to recover hemicelluloses and lignin.

![1216.5.2013

Eemeli Hytönen, Concept evaluations, FuBio Seminar, 27.8.2013

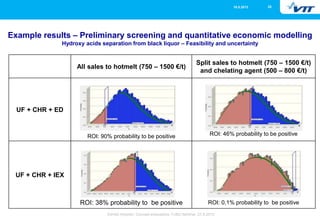

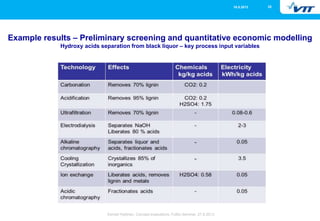

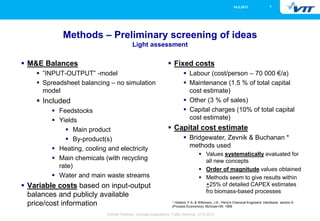

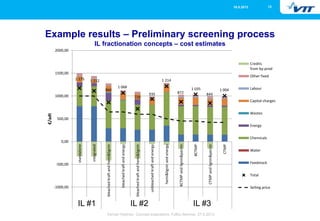

Example results – Preliminary screening process

IL fractionation methods

IL #1 IL #2 IL #3

Raw material Birch kraft pulp birch spruce

Products Dissolving pulp 76% "kraft-like” pulp 57% ”CTMP-like” pulp 90-95%

Hemicellulose 24 % lignin, hemi 43% Pectin, hemi, lignin 5-10%

Ionic liquid [Emim]OAc Switchable ionic liquid [Emim]Me2PO4

(and water) DBU, MEA, CO2/SO2

Antisolvent water ethanol Isopropanol

Antisolvent recovery

method evaporation distillation evaporation

Production scale 150 000 adt/a 700 000 adt/a 250 000 adt/a

• Total 11 concepts](https://image.slidesharecdn.com/9hytnen-concept-evaluations-130920062413-phpapp01/85/Concept-evaluations-12-320.jpg)

![1916.5.2013

Eemeli Hytönen, Concept evaluations, FuBio Seminar, 27.8.2013

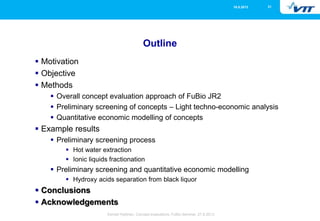

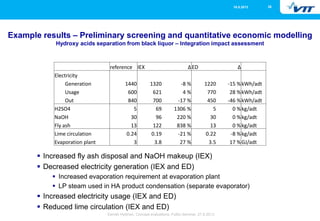

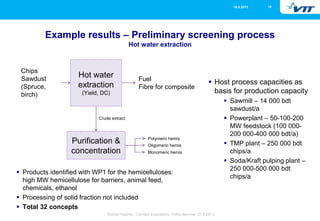

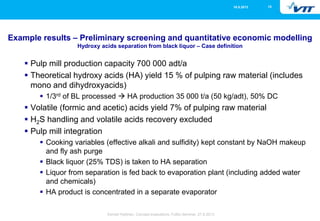

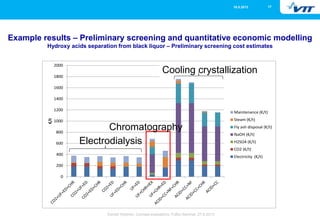

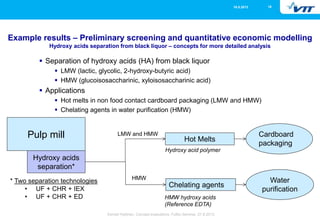

Example results – Preliminary screening and quantitative economic modelling

Hydroxy acids separation from black liquor – Integration impact assessment

Pulp mill reference

model (WinGems-

simulation software) *

Capacity 700 000 adt/a.

Process water usage ~

15 m3/adt. Based on

BAT technologies

SPLIT

dust dump

141

M IX

M i x30

30

M IX

M i x26

26

BLEACHING

Bl eachi ng

25

WW-T REAT

Ef f l uent

tr eatment

24

ST ORE

Par ameter s

23

DEBARKIN

Debar ki ng

22

M IX

21

SUM

Steam 4.2 bar

20

T RACOM P

Addi ng of

tr ace

components

16

M IX

15

PID

Pi d14

14

SUM

Steam 13 bar

13

ST ORE

Pr oducti on

12

DRYEND

Dr yer secti on

11

SPLIT

Spl i t1010

T URB_PLANT

T ur bi ne pl ant

6

EVAPO

Evapor ati on

5

BOILERS

Boi l er pl ant

4

ST ORE

Wood

par am

i nput

3

RECOVERY_SK

Whi te l i quor pr epar ati on

2

DELIGNIFICA

Cooki ng and oxygen d

1

348t/h

42 t/h

123 t/h

Effluent 1740 t/h

0 t/h

Shaft power 95.1 MW

Floor channel 120 t/h, TDS 5 g/l

Wood properties:

1) I:Wood temp.[C]15

2) I:Dry contentofwood [%]50

3) I:Cellulose in wood [%]44.1

4) I:Hemicellulose in wood [%]30.7

5) I:Lignin in wood [%]23.9

6) I:Extractives in wood [%]1.6

102 t/h

Water 100 t/h

Pyrolysis gas

properties

69 t/h

71 t/h

Bark 46 t/h,

30 °C, 40 %

104 t/h, TDS 11 g/l

Wood 404 t/h,

15 °C, 49 %

Sootblowing steam 16 t/h, 30 bar

LP 6 t/h

MP 71 t/h

MP 76 t/h

195 t/h

LP 91 t/h

MP 32 t/h

MP 16 t/h

LP 26 t/h

227 t/h

Acidic filtrate 867 t/h, TDS 4 g/l

Cond. B 278 t/h

Saltcake 5 t/h

Bio-sludge 0 t/h

0 %

Alkaline filtrate 649 t/h, TDS 8 g/l

900 t/h

636 t/h

Air 695 t/h

24 °C

CTO 0 t/h

Water 351 t/h

BL 933 t/h,

TDS 132 kg/t

Pulp 100 t/h, 75 °C, 90 %

1:Bark contentofwood:10 w-%

2:Wood LHV:19.35 MJ/kgDS

3:Wood HHV:19.3 MJ/kgDS

4:Notin use

5:Bark Dry content:40 %

6:Carbon fraction in bark:0.5159

7:Oxygen fraction in bark:0.4069

8:Hydrogen fract.in bark:0.0577

9:Sulfur fraction in bark:3.000E-04

10:Ash fraction in bark:0.0192

11:Gasification lost:6 %

Water

LP 104 t/h

Cond. A 421 t/h

Boiler blow-down 6 t/h, 103 bar, 313 °C

BFW 604 t/h, 120 bar, 187 °C

13bar

4.2bar

7bar0t/h

Chips 355 t/h, 15 °C, 50 %

Saltcake 1.4 t/h

LP-condensate 267 t/h

Pyrolysis gas

180 t/h, 66 °C, 50 %

HP -steam 598 t/h, 103 bar, 505 °C

Flue gas 806 t/h

183 °C

Smelt 63 t/h

Bark parameters

Oxidised WL

WL 346 t/h, AA 113 g/l

BL156t/h,

TDS822kg/t

MP-condensate 140 t/h

* Kangas, Kaijaluoto and Määttänen (2013), Evaluation of Future Pulp Mill Concepts – Reference Model of Modern Nordic Kraft Pulp Mill, to be submitted to NPPRJ](https://image.slidesharecdn.com/9hytnen-concept-evaluations-130920062413-phpapp01/85/Concept-evaluations-19-320.jpg)