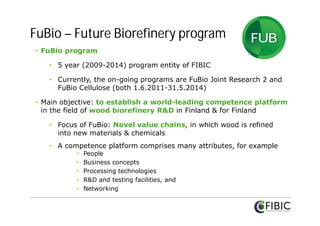

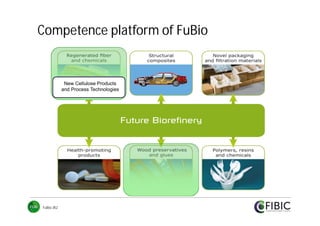

1) The FuBio Joint Research 2 program aims to establish a world-leading competence platform in wood biorefinery R&D in Finland through research projects, publications, patents, and industry collaboration.

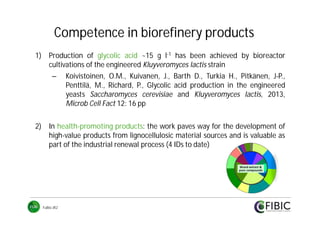

2) The competence platform includes people, business concepts, processing technologies, R&D facilities, and networking. To date there have been over 80 publications, 100 conference presentations, 5 completed PhDs, and 10 patent applications.

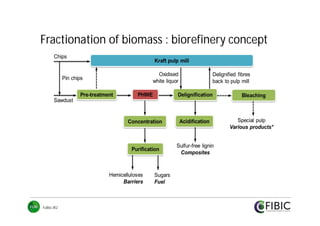

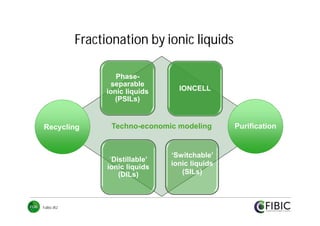

3) Research has led to new processing technologies and solutions, techno-economic models of business concepts, and opportunities for industry partners to work with researchers on product development. The program has advanced wood biorefinery capabilities in Finland.