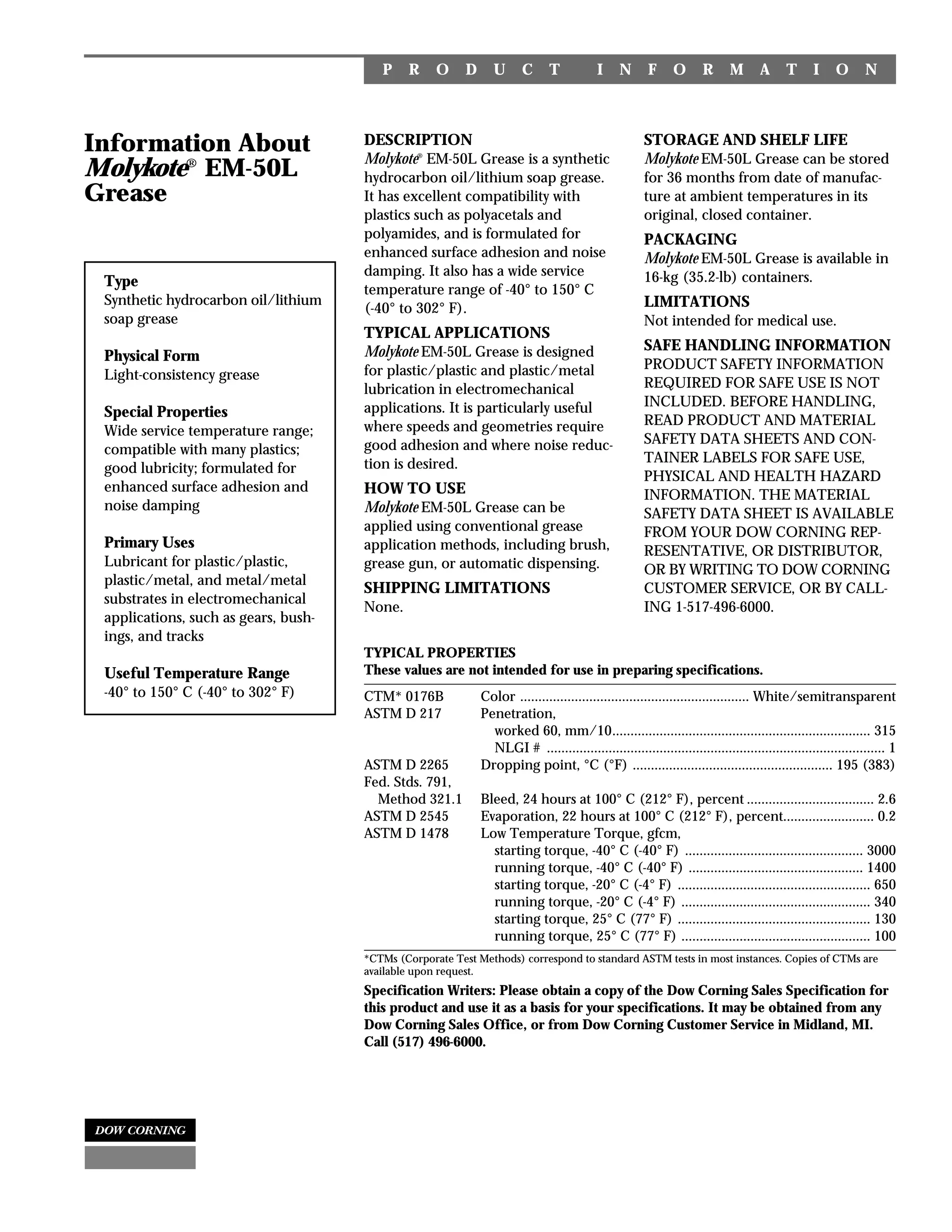

Molykote EM-50L Grease is a synthetic hydrocarbon oil/lithium soap grease with a wide service temperature range from -40 to 150 degrees Celsius. It is compatible with many plastics and formulated for enhanced surface adhesion and noise damping. The grease is available in 35-pound containers and is designed for lubricating plastic/plastic, plastic/metal, and metal/metal components in electromechanical applications. Safety information is available from the manufacturer.