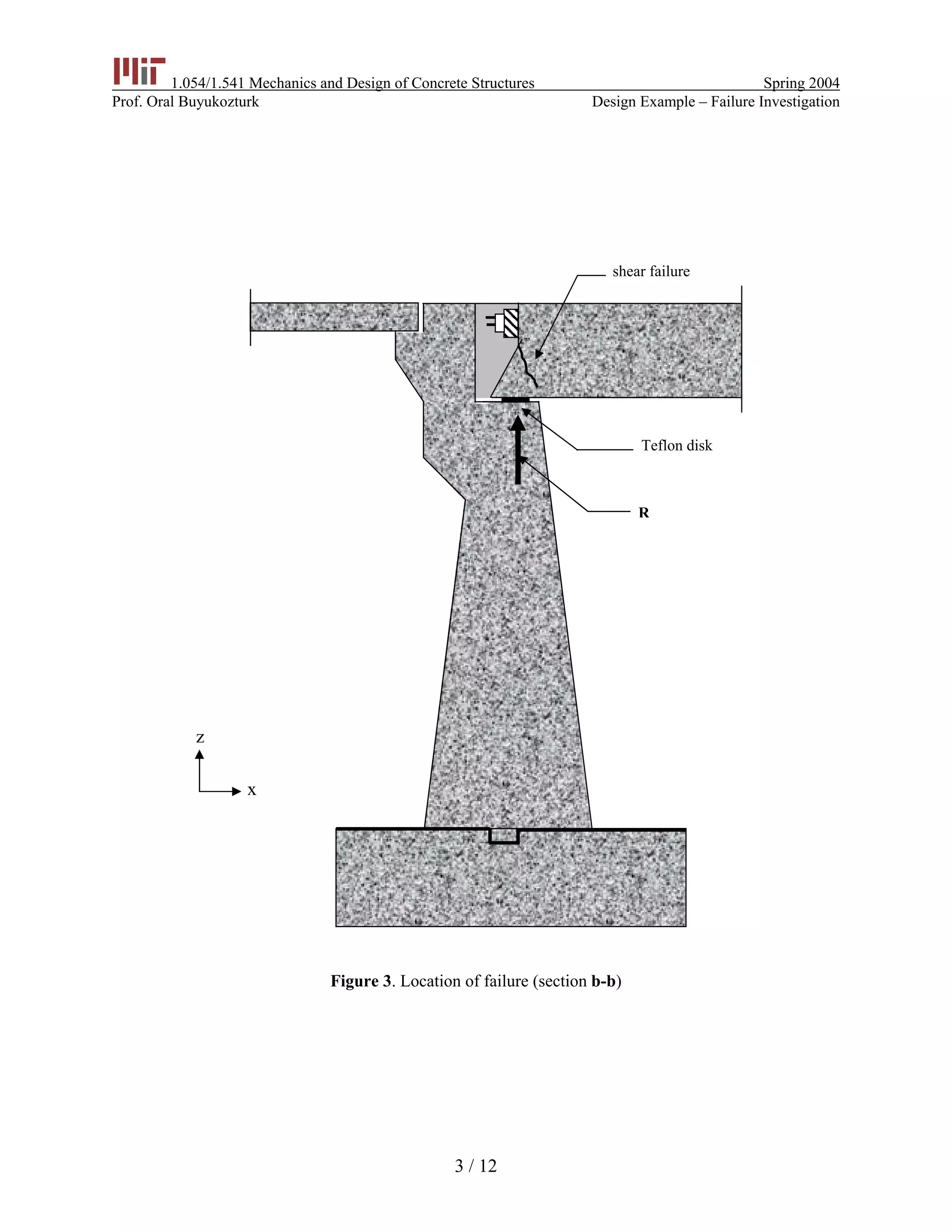

The document summarizes an investigation into the failure of prestressed concrete bridge girders. It was found that:

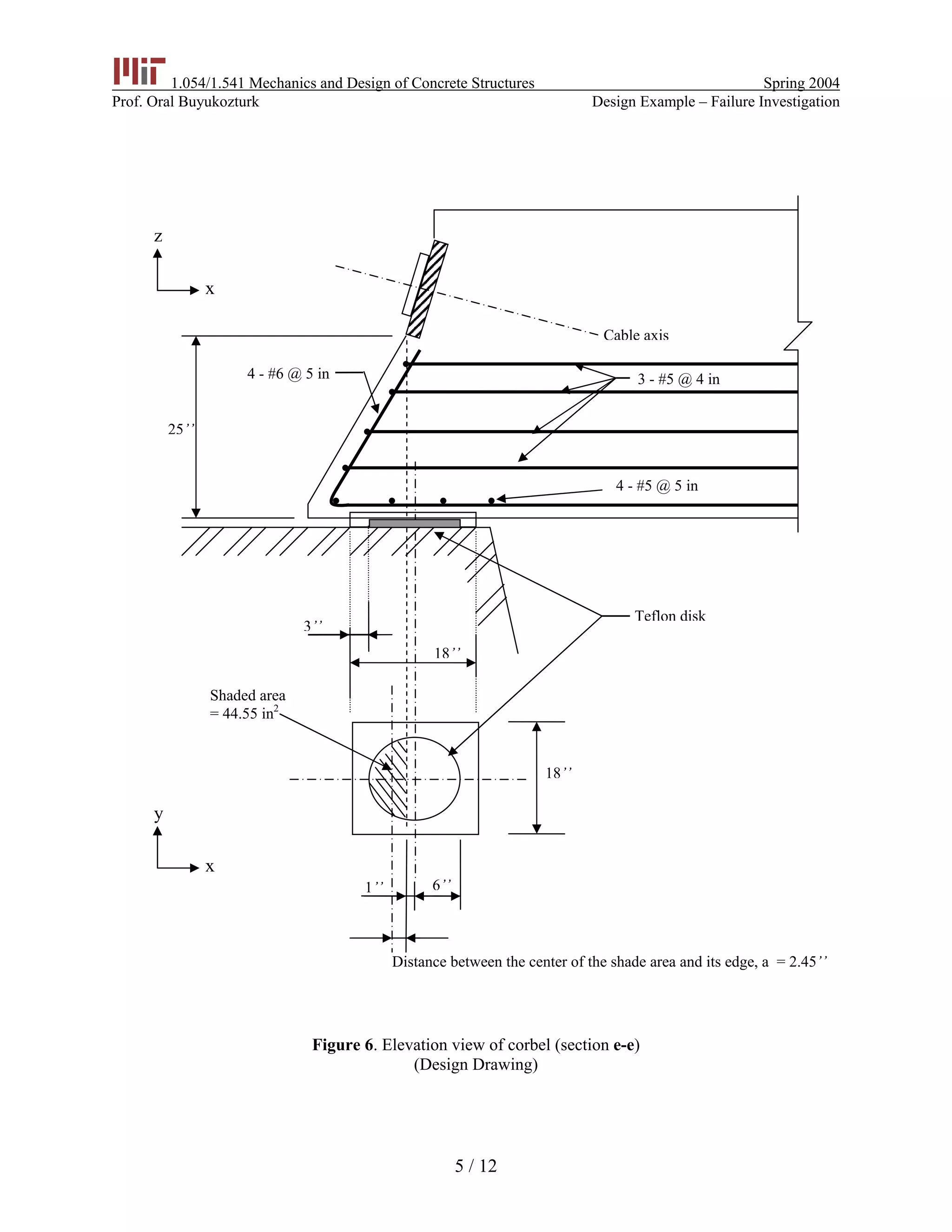

1) The original design of the corbels was adequate according to code.

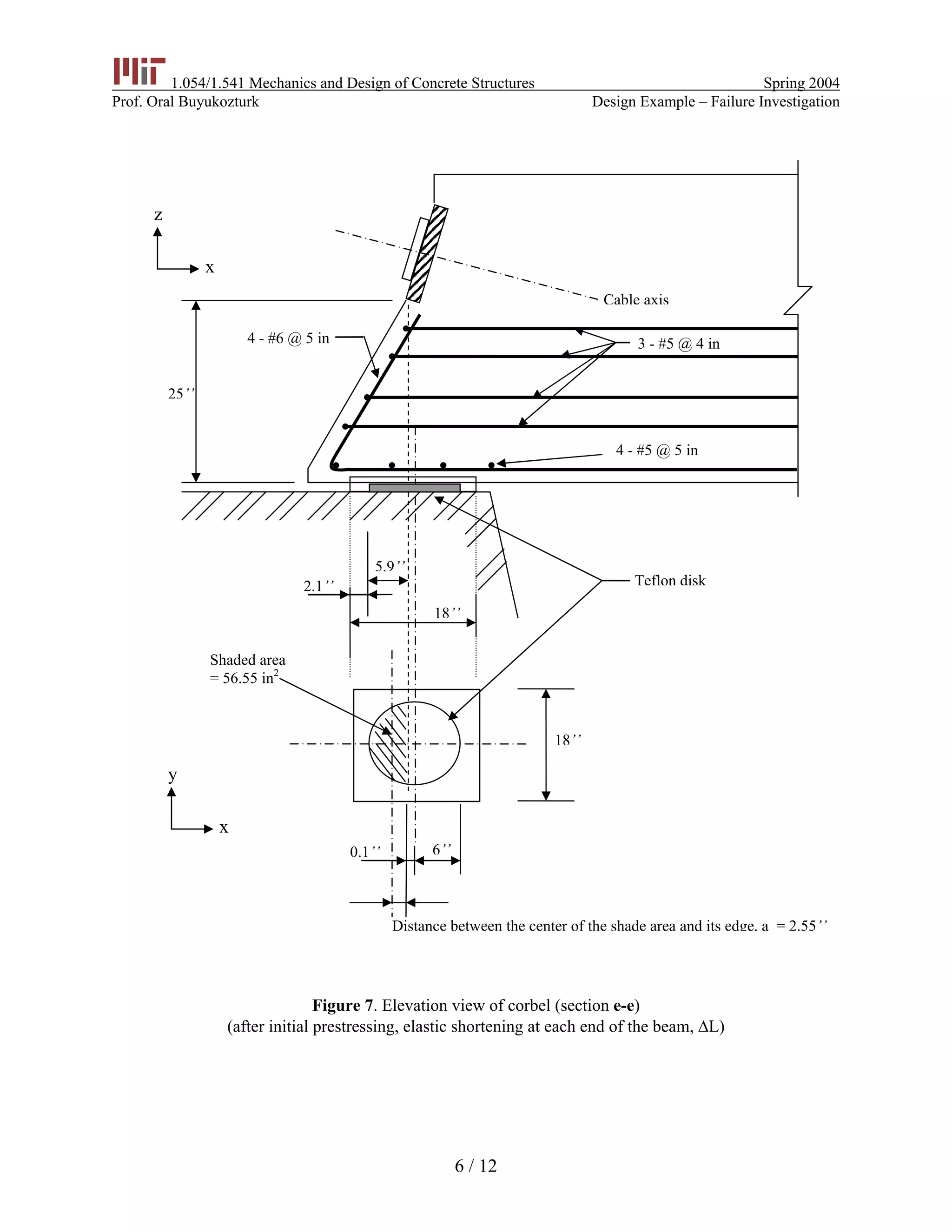

2) However, when elastic shortening of the beams was considered, the design was inadequate.

3) With both elastic shortening and the hypothesized misplacement of teflon disks, the design was clearly deficient in strength.

4) The likely causes of failure were poor design that did not adequately account for elastic shortening, as well as potential misplacement of materials during construction.