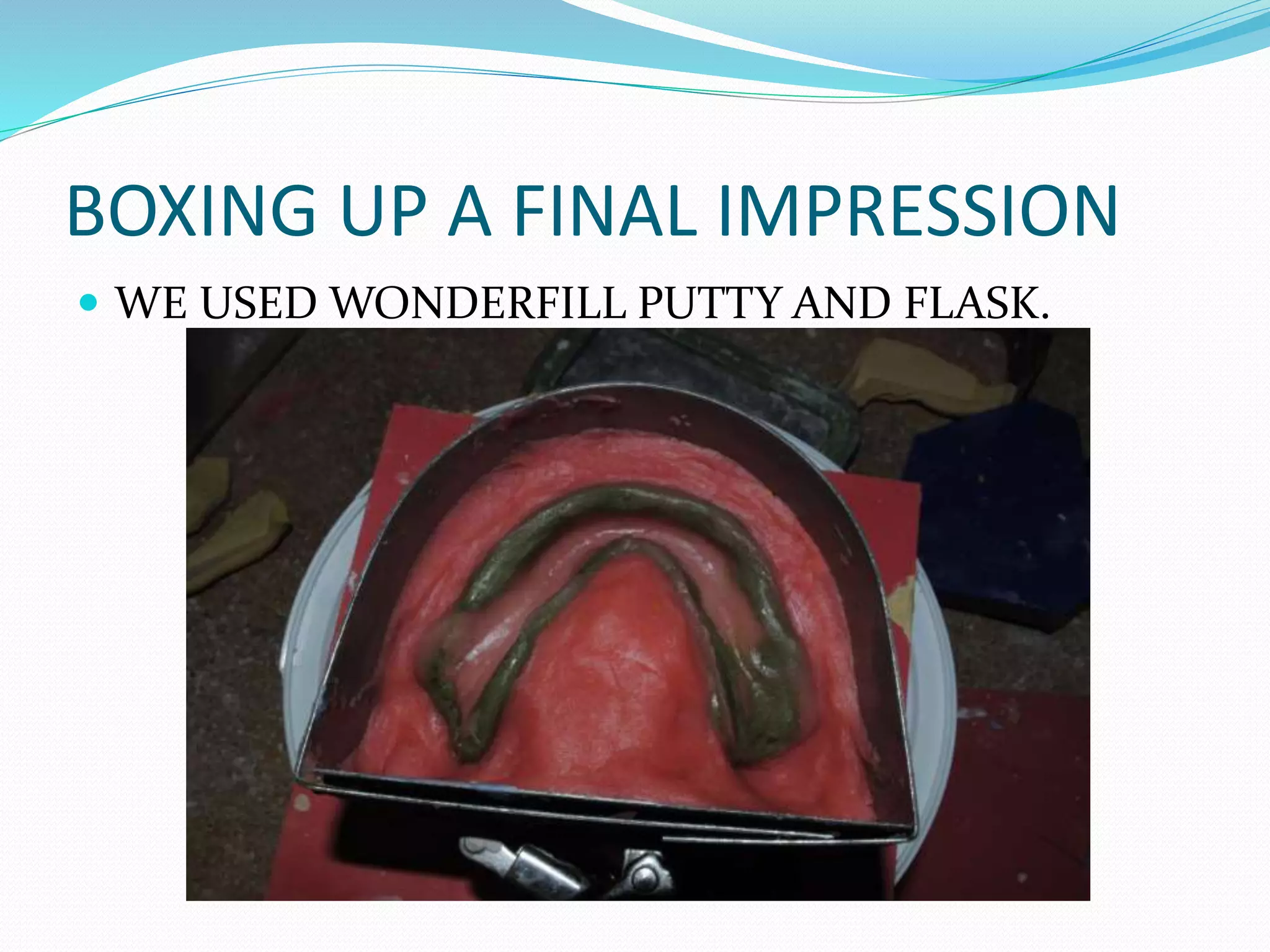

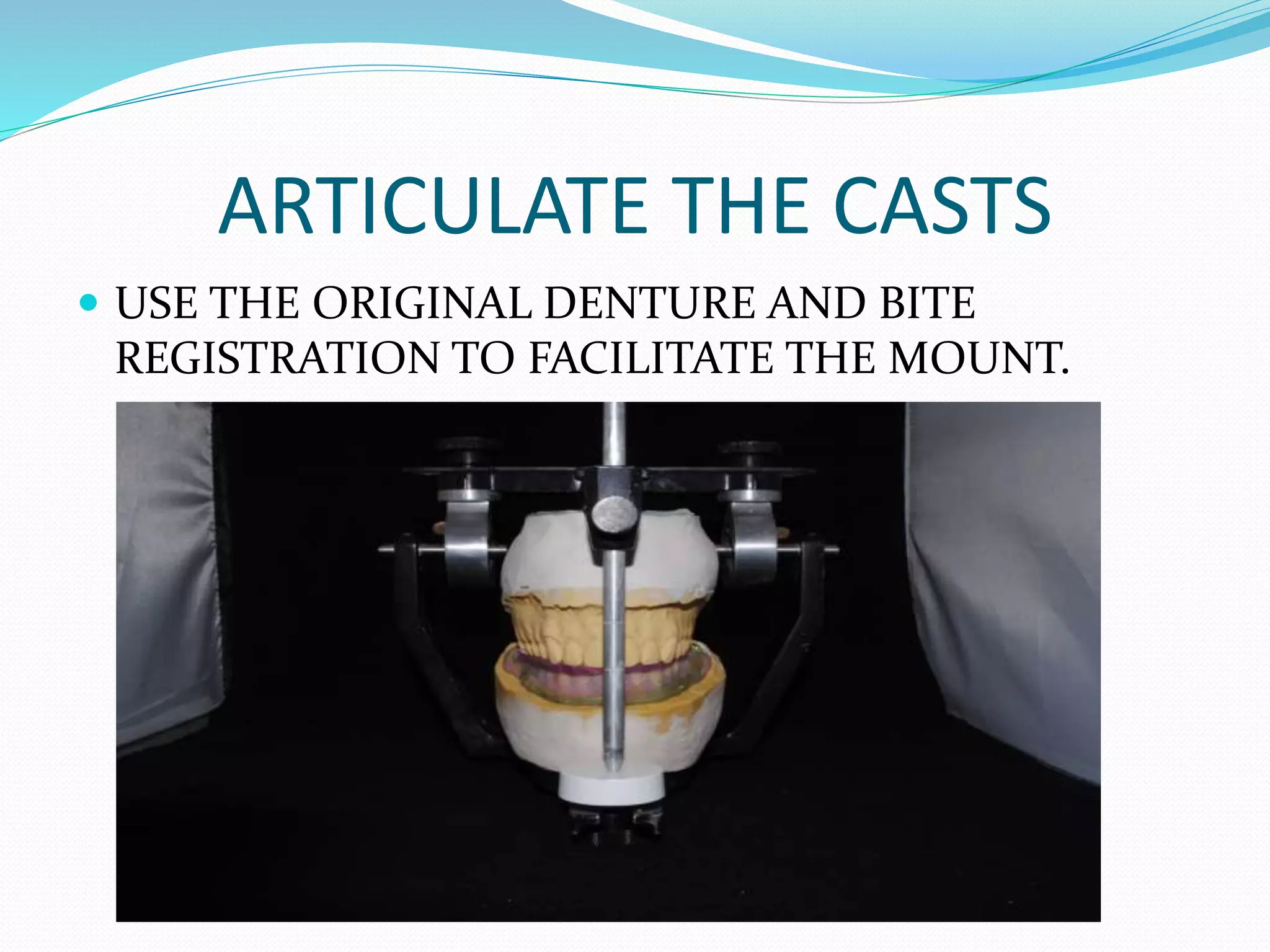

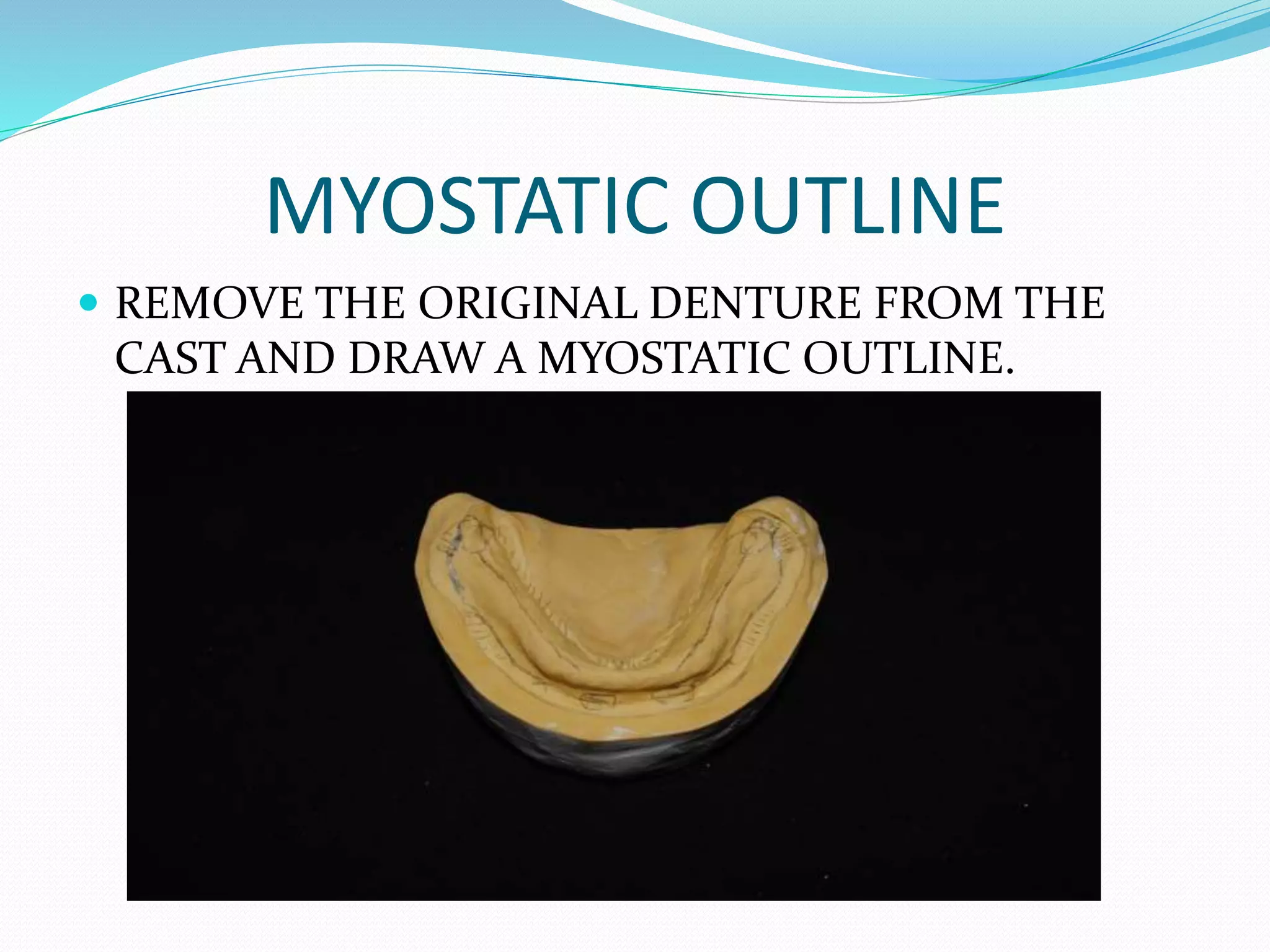

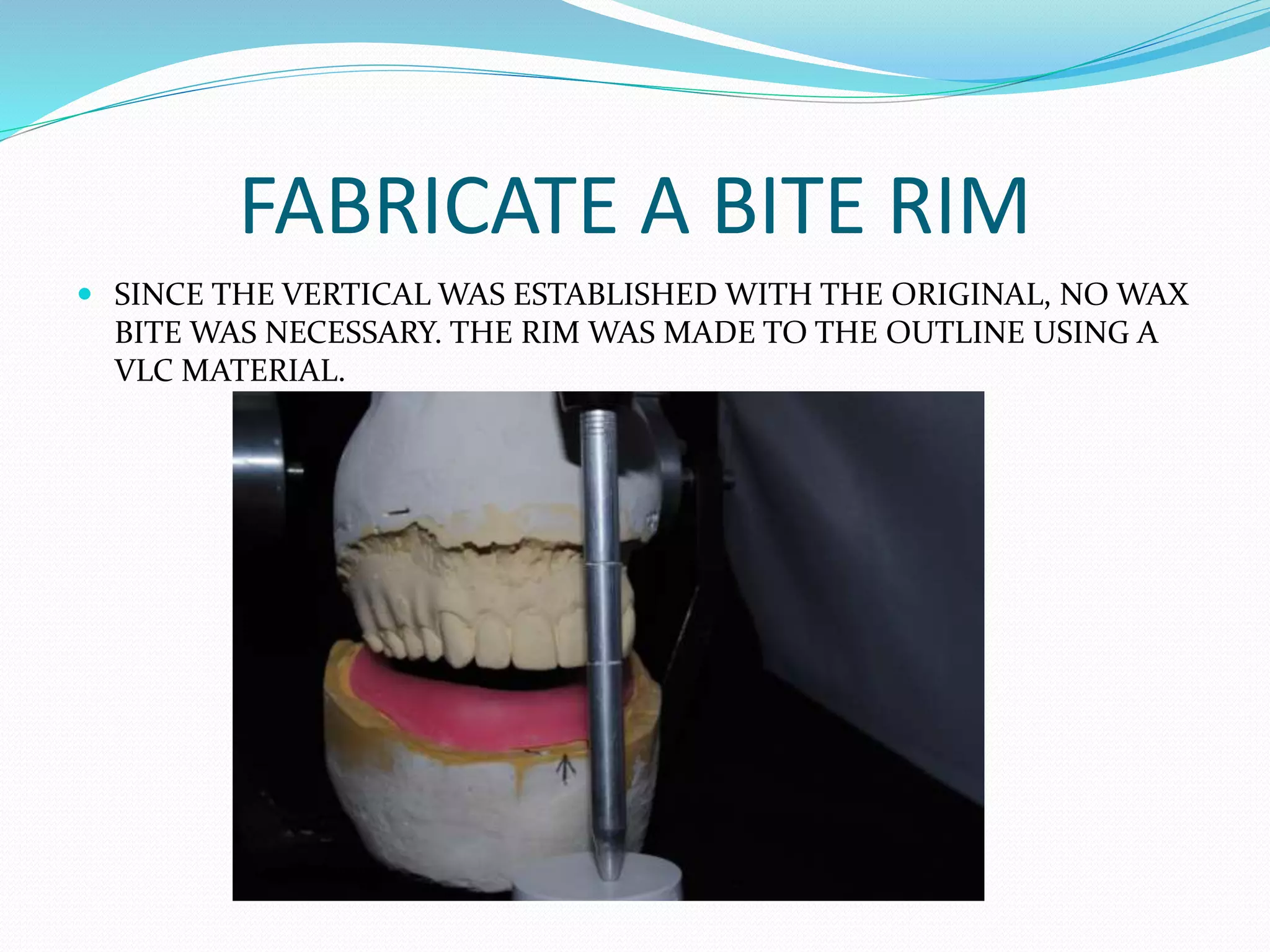

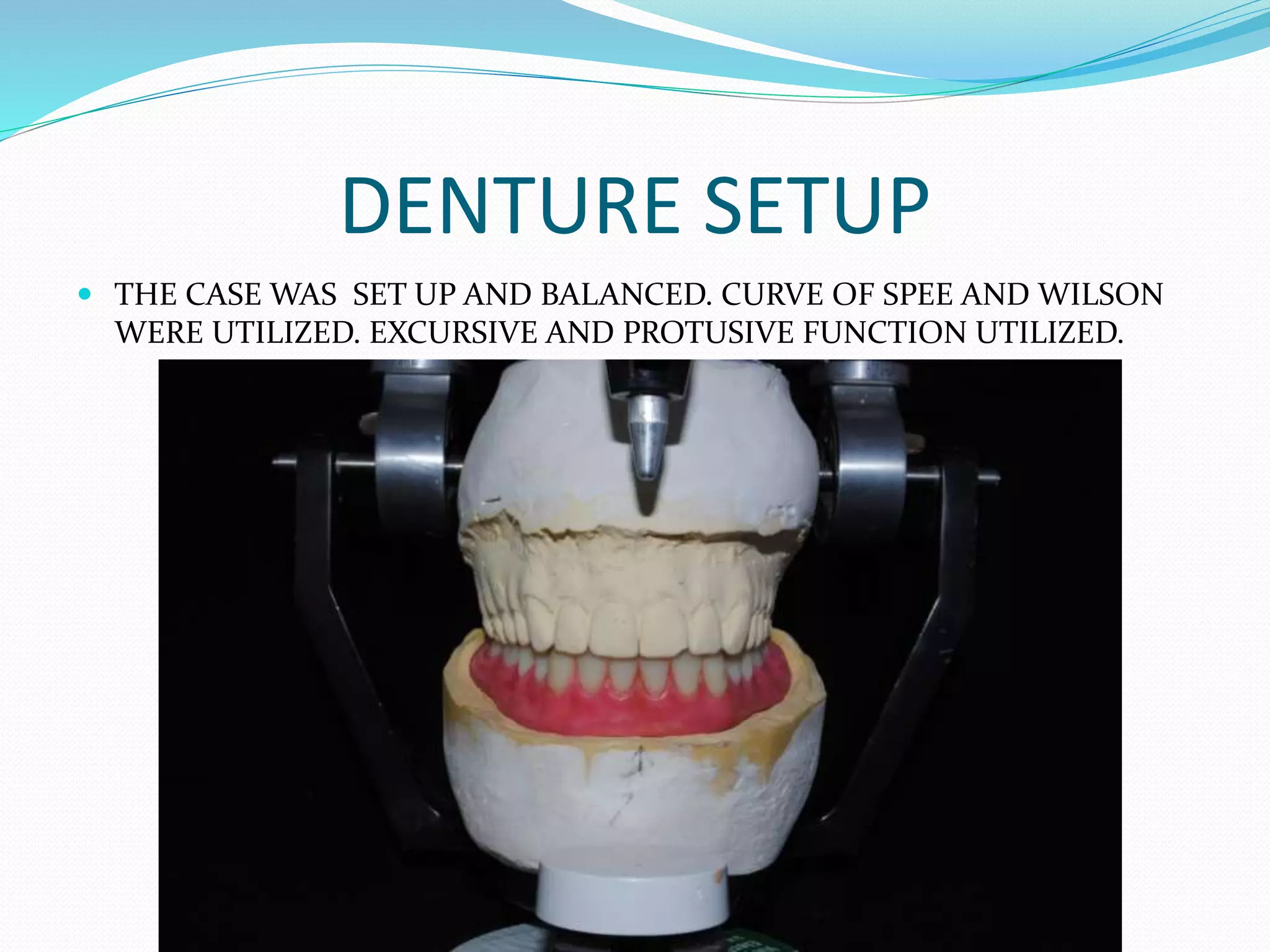

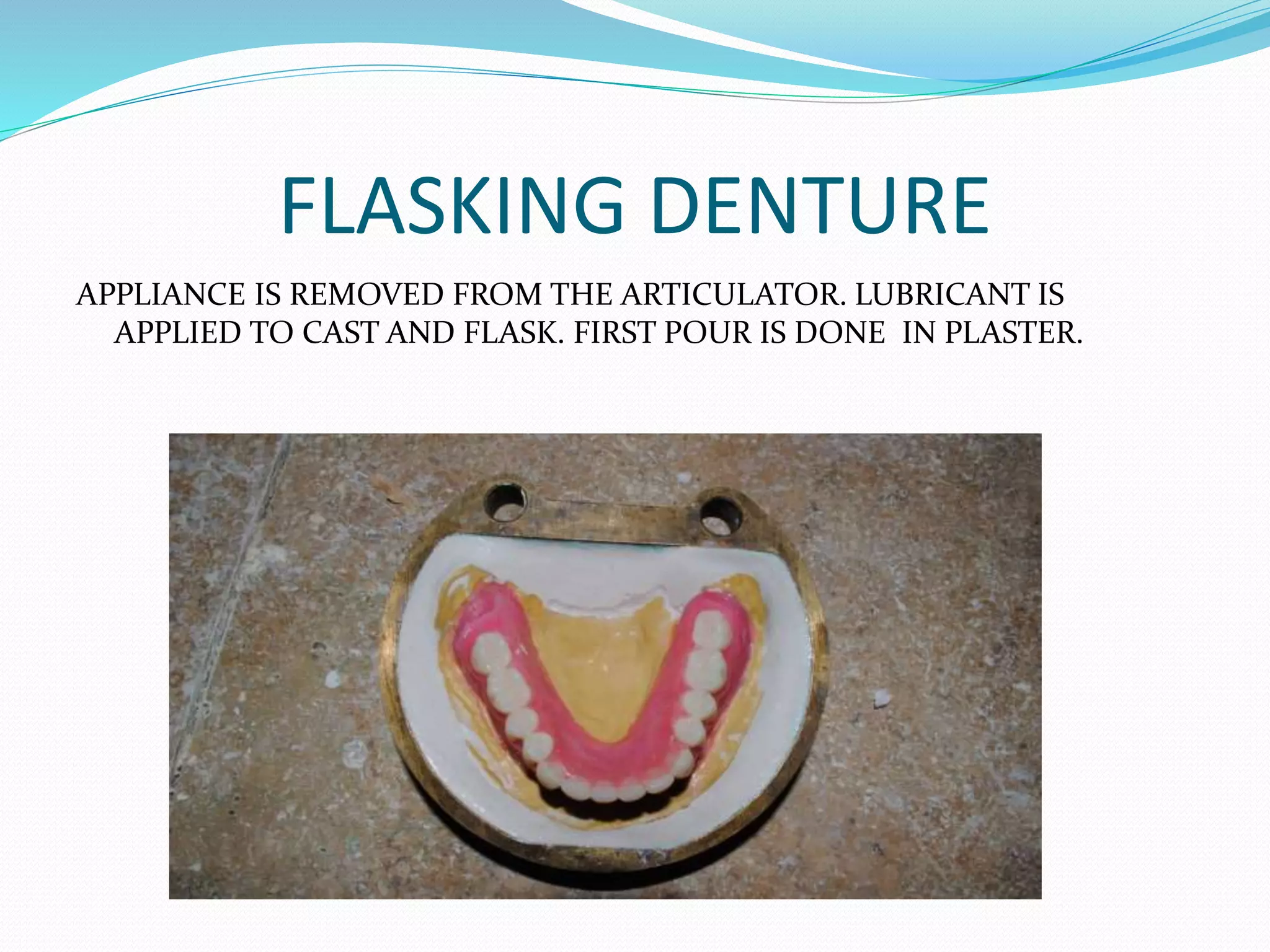

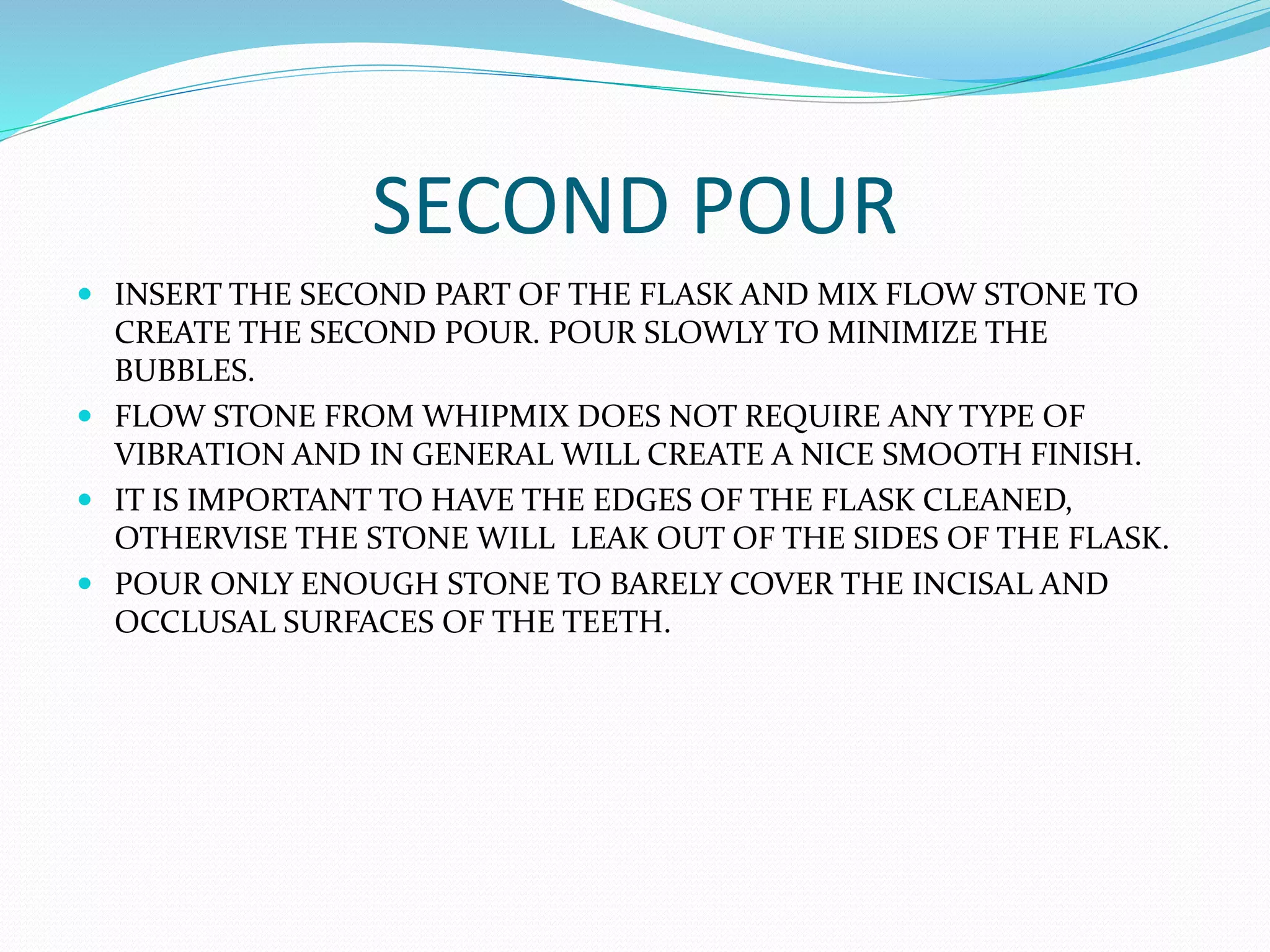

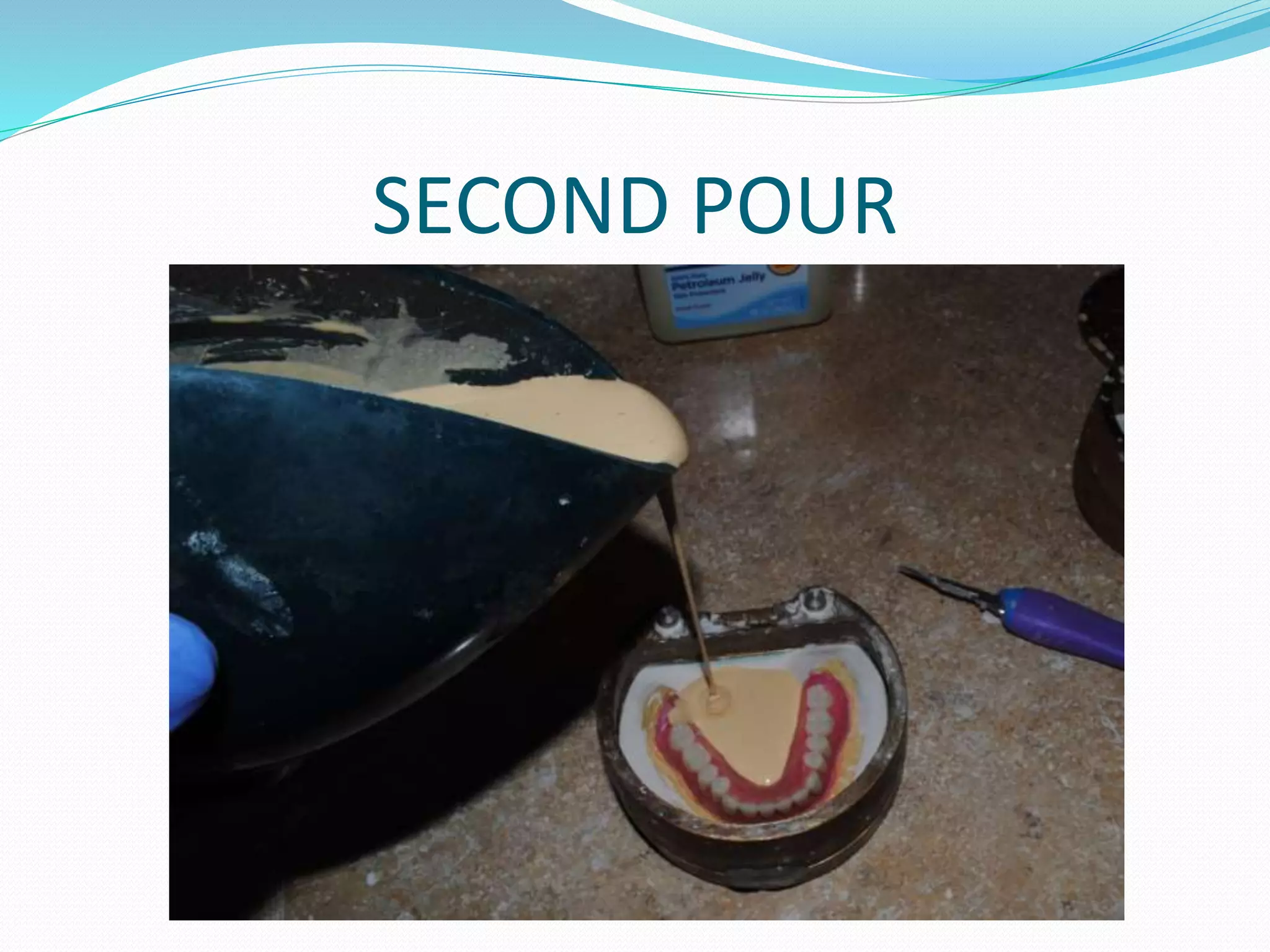

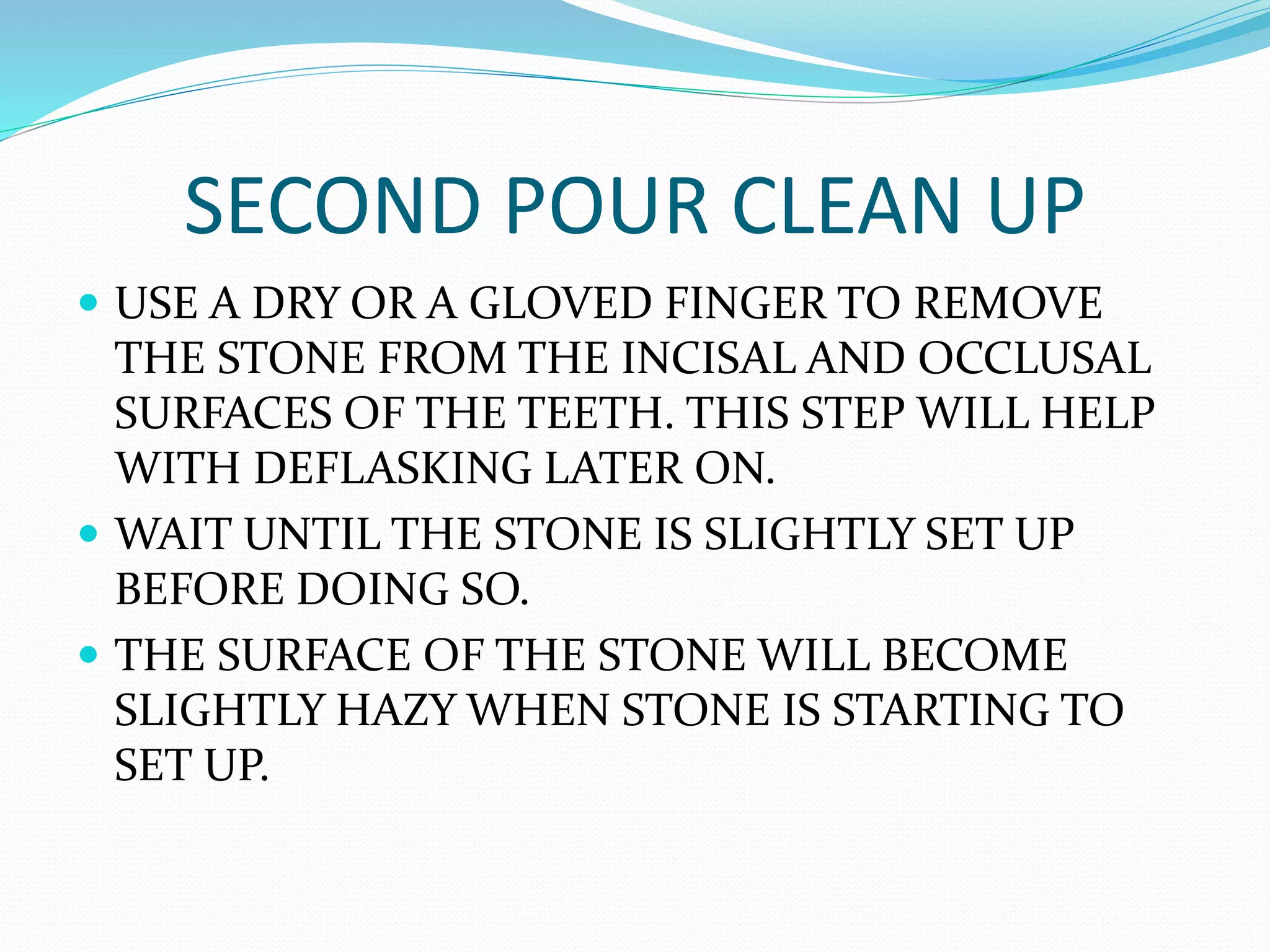

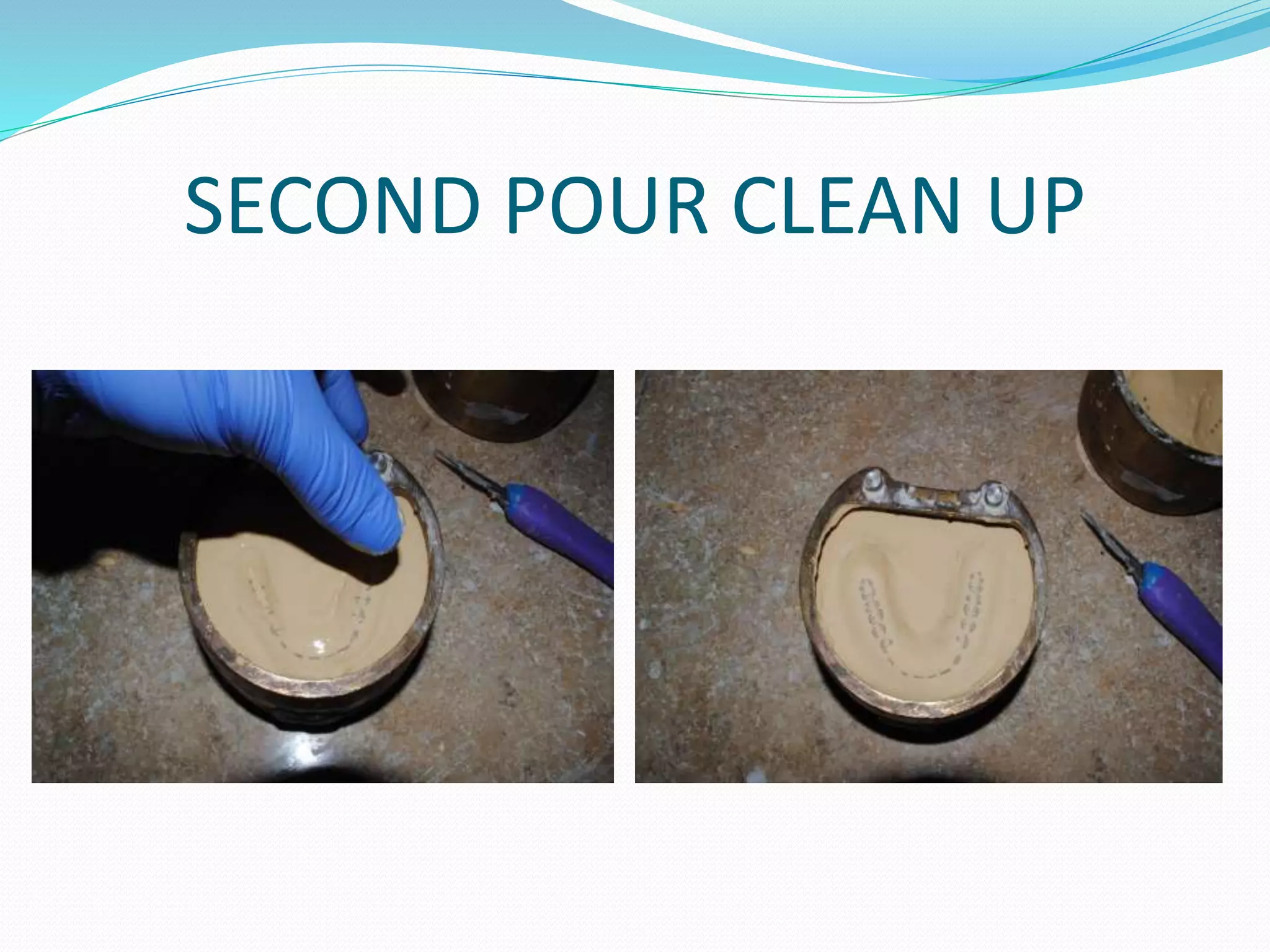

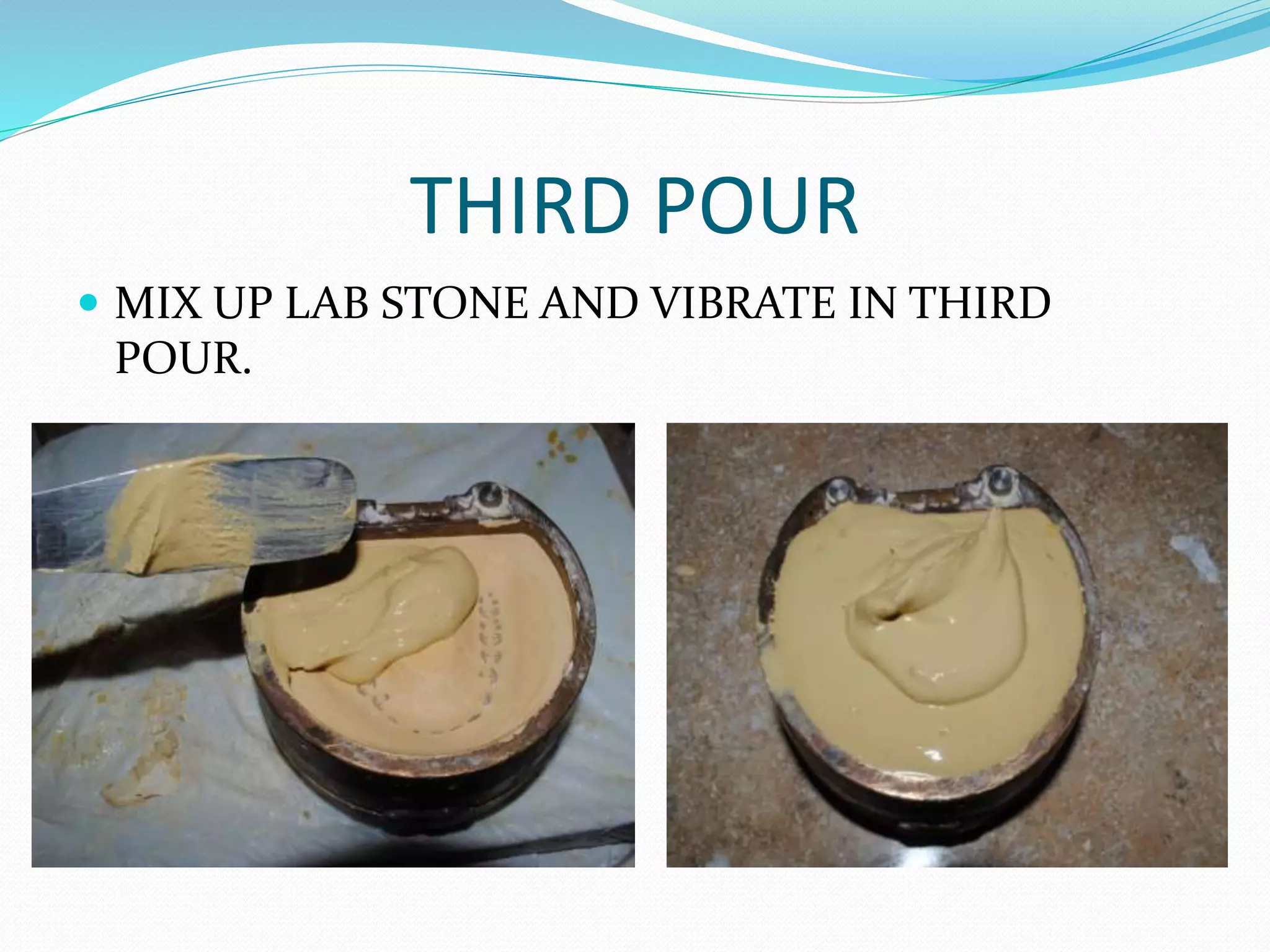

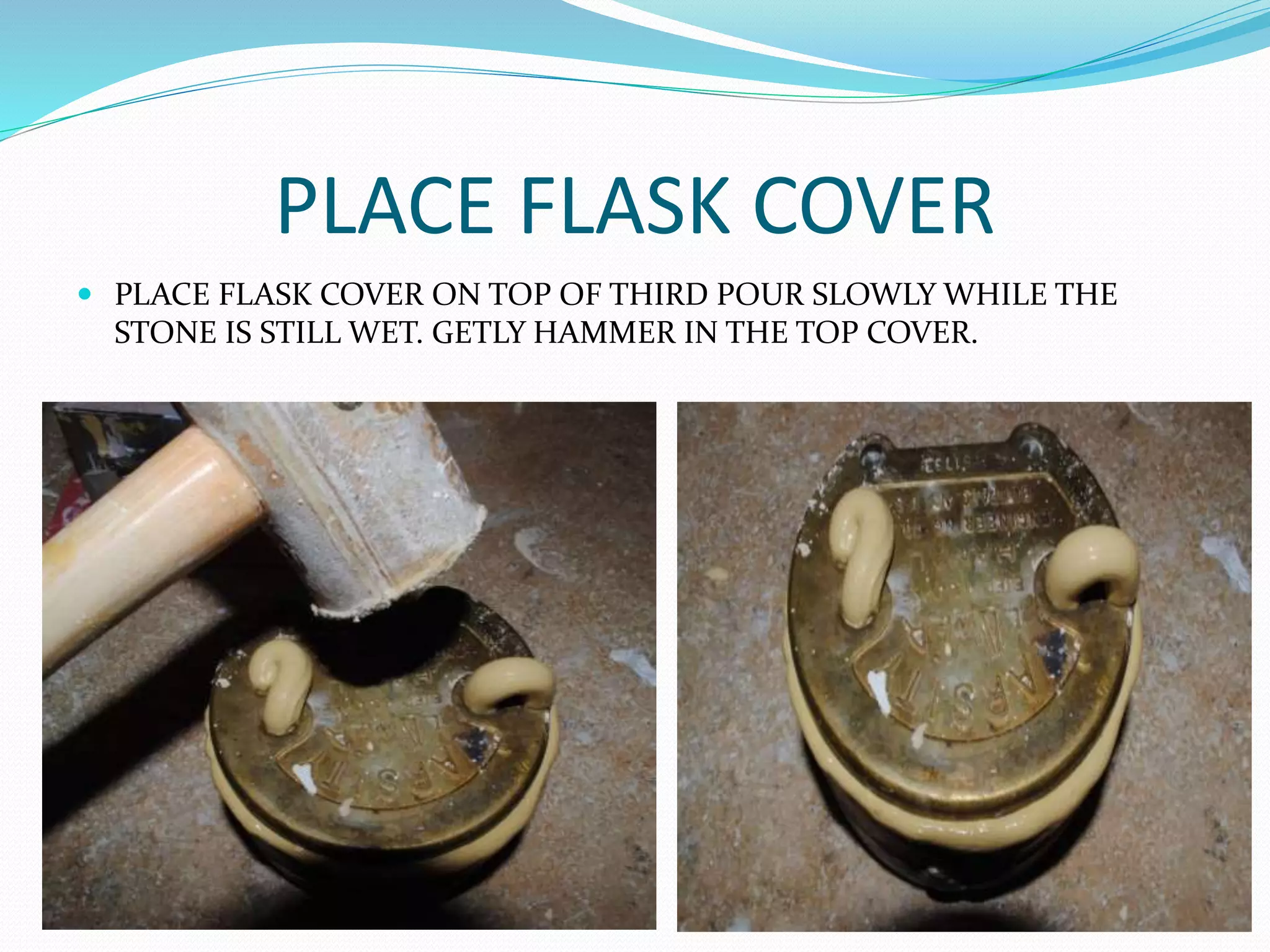

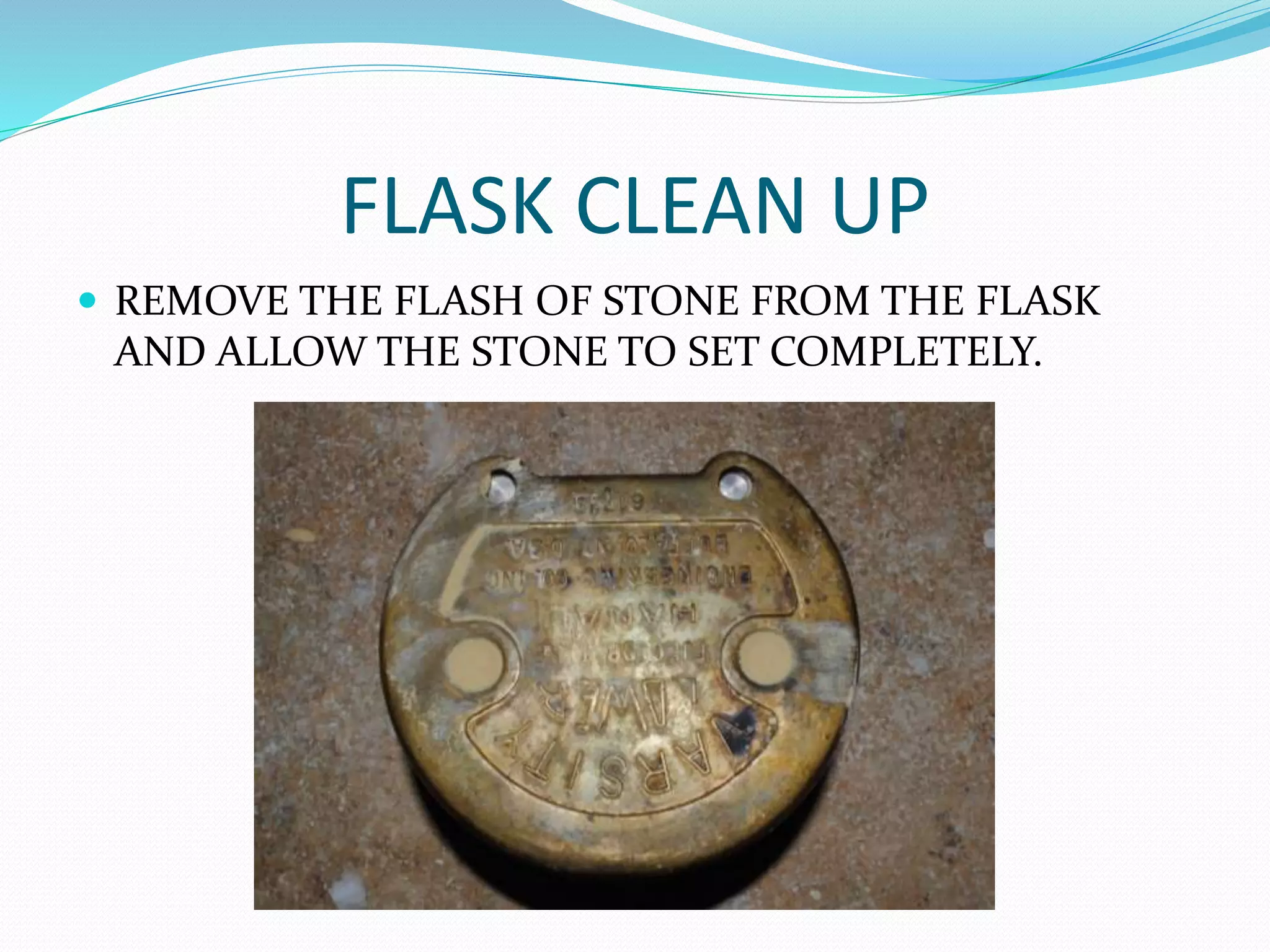

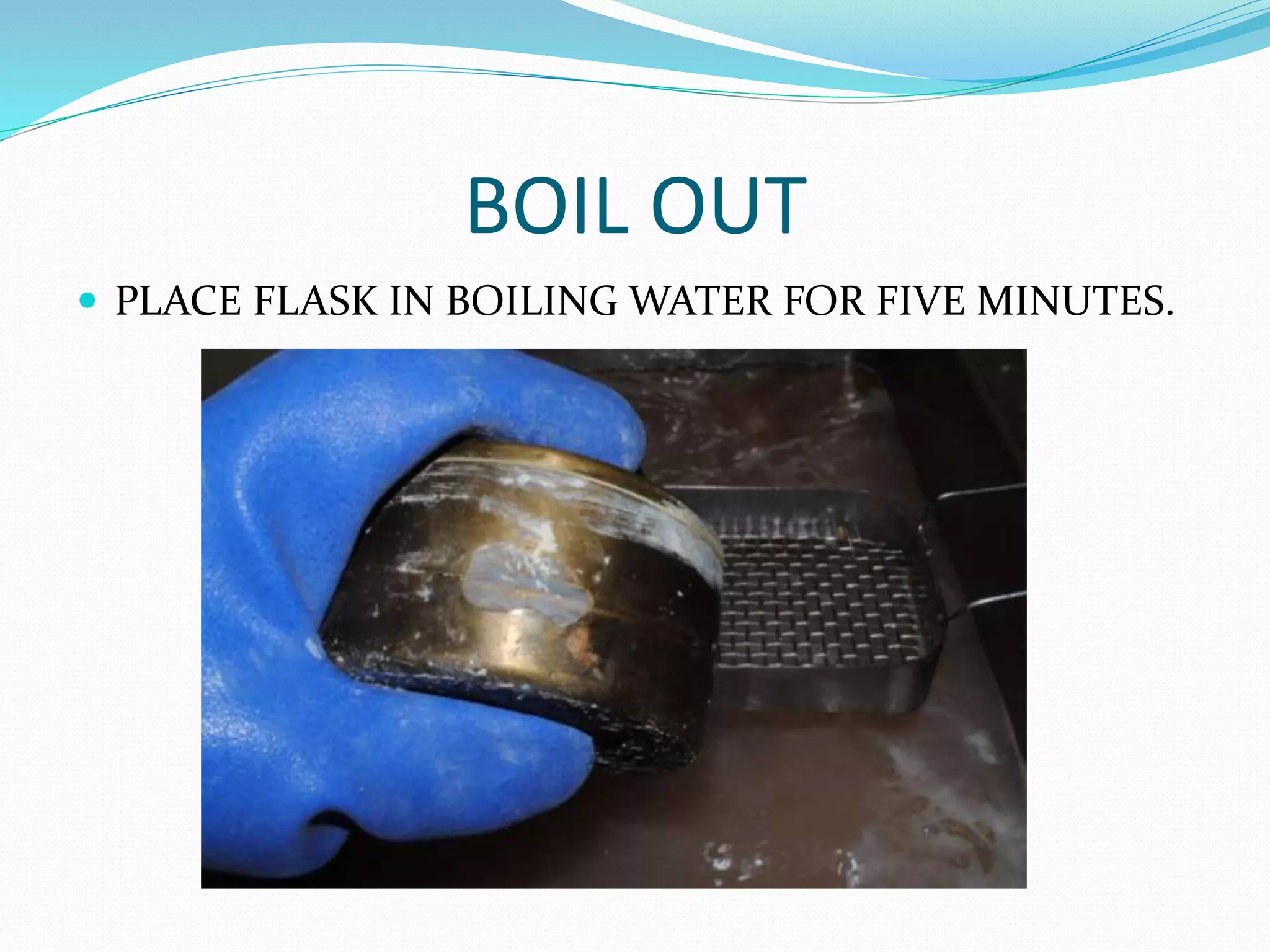

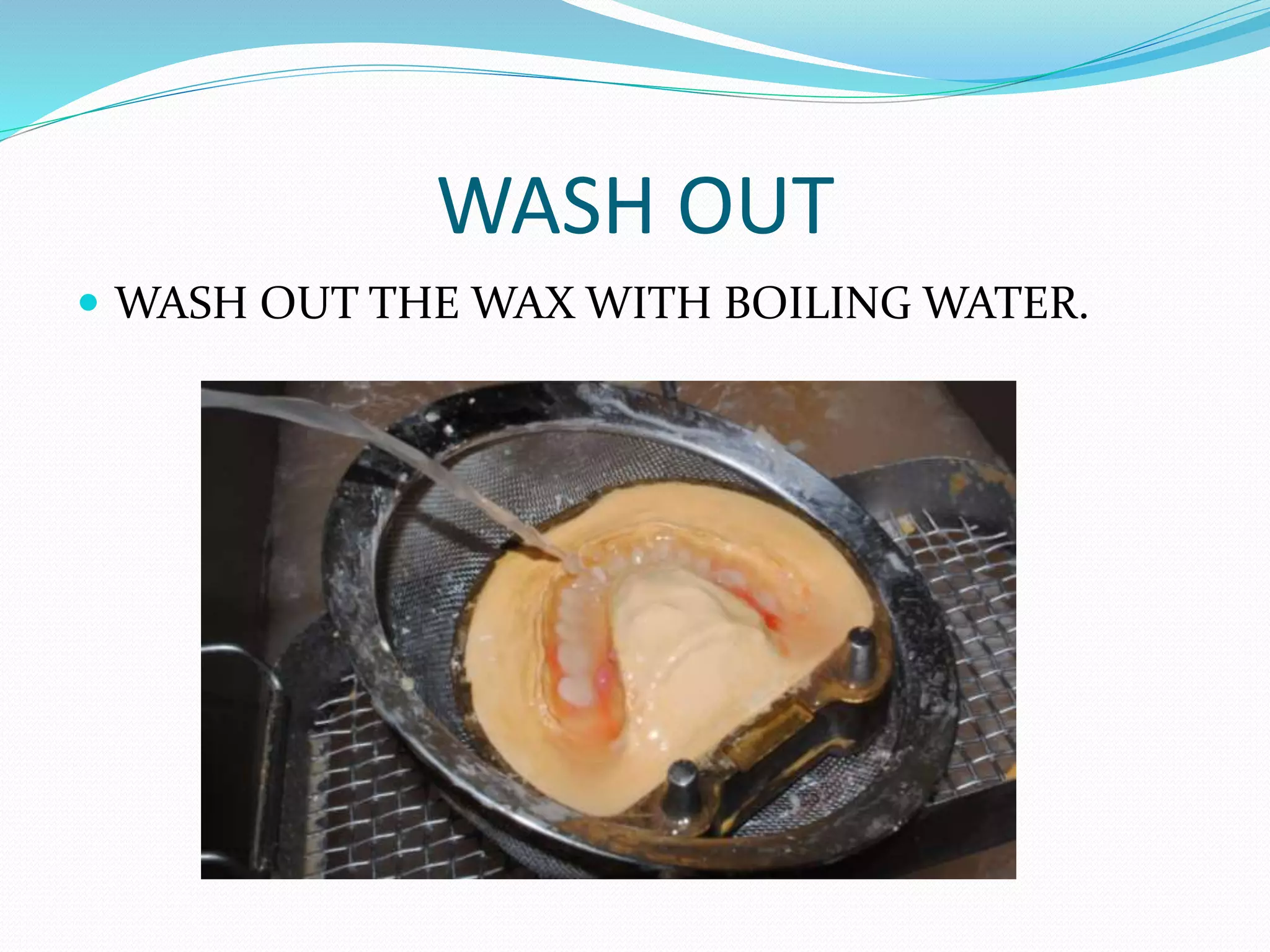

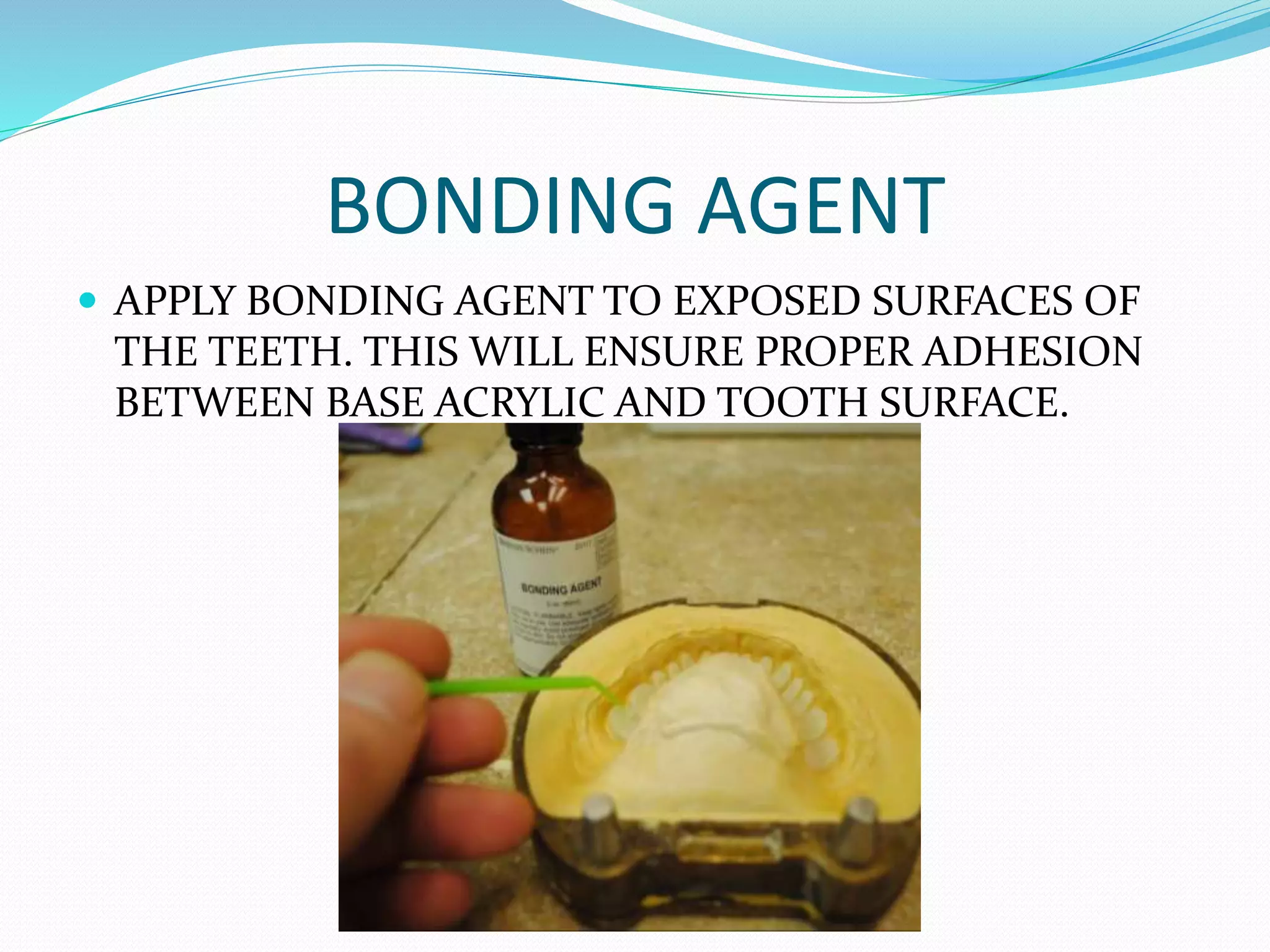

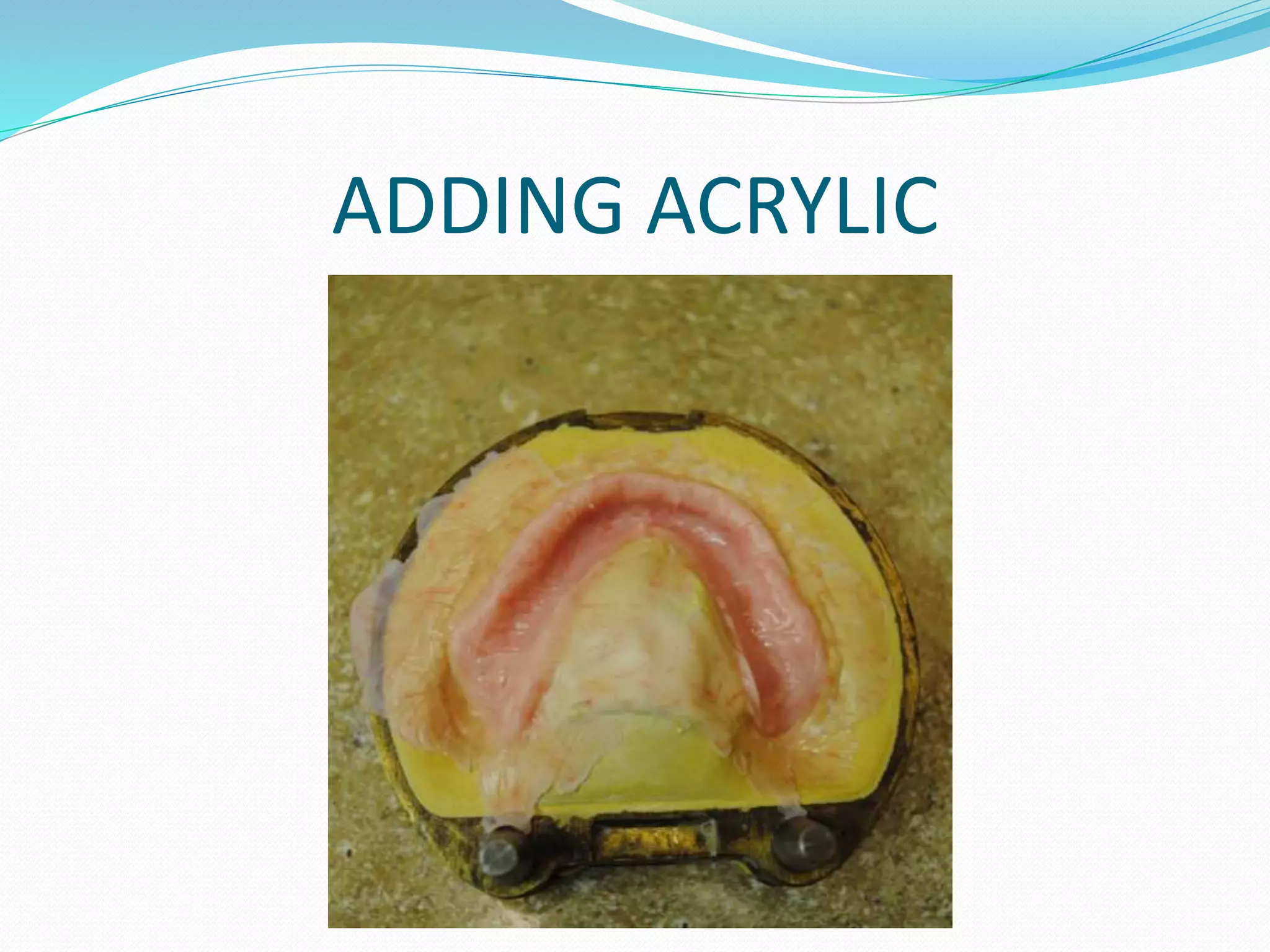

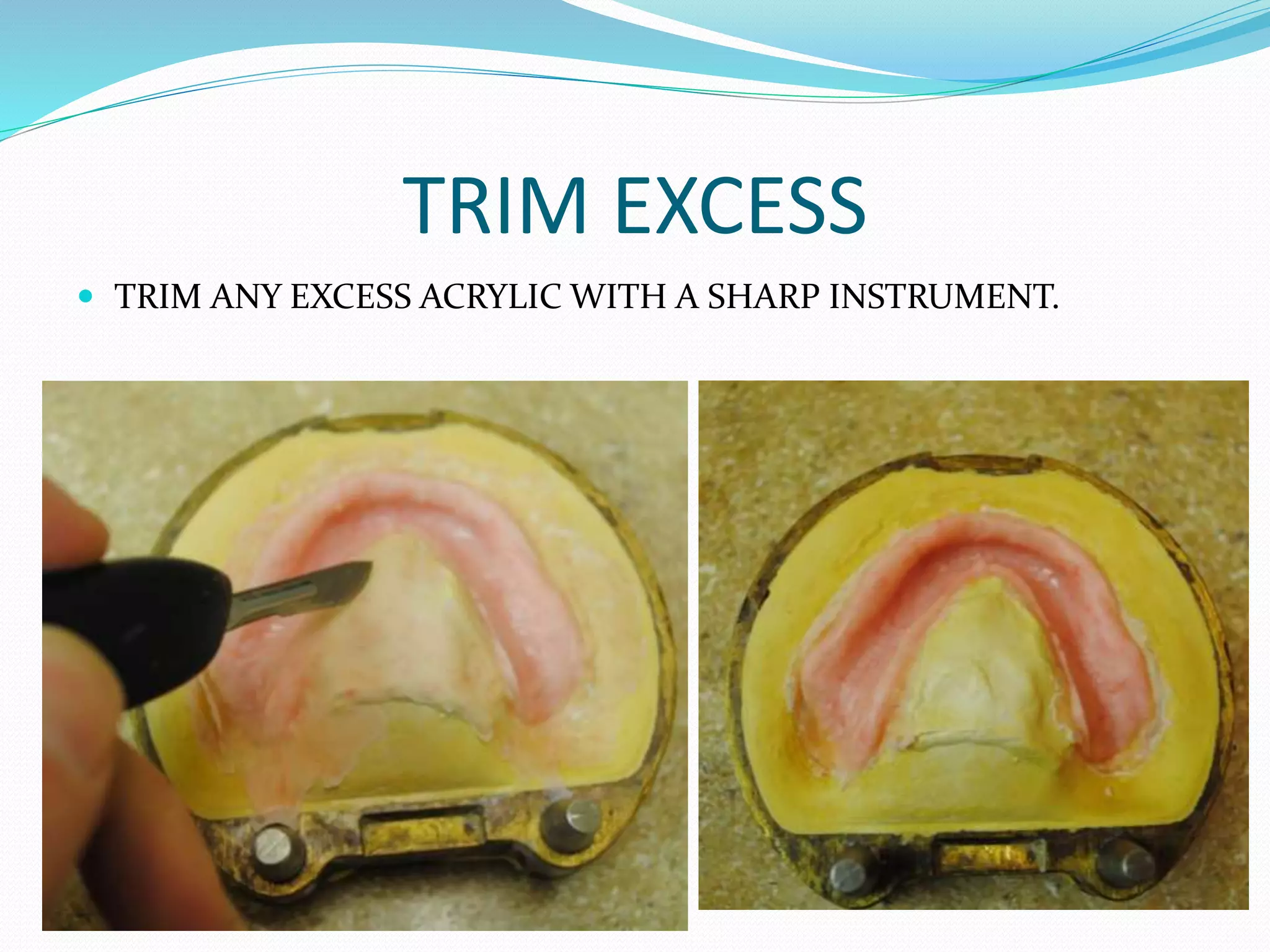

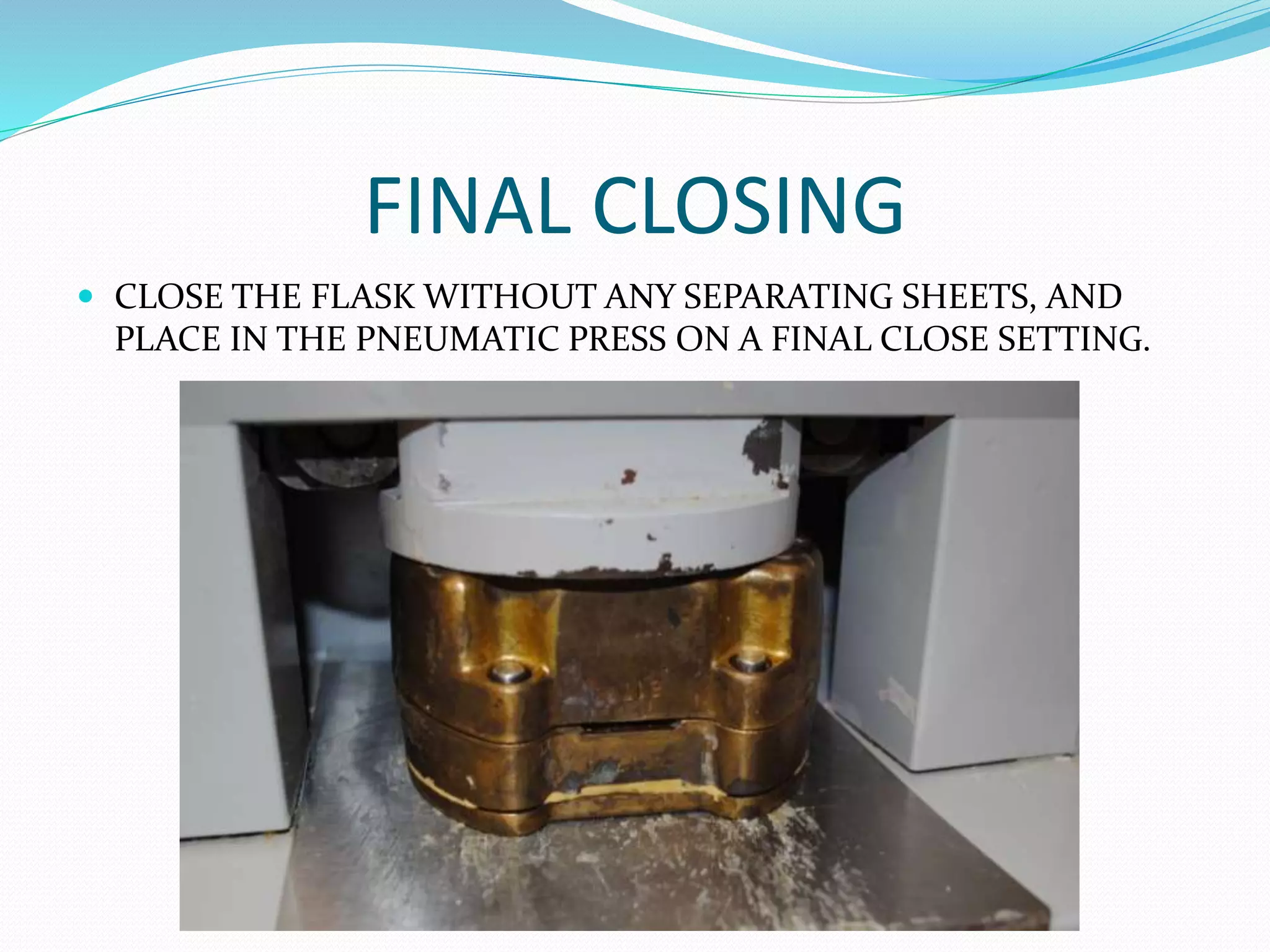

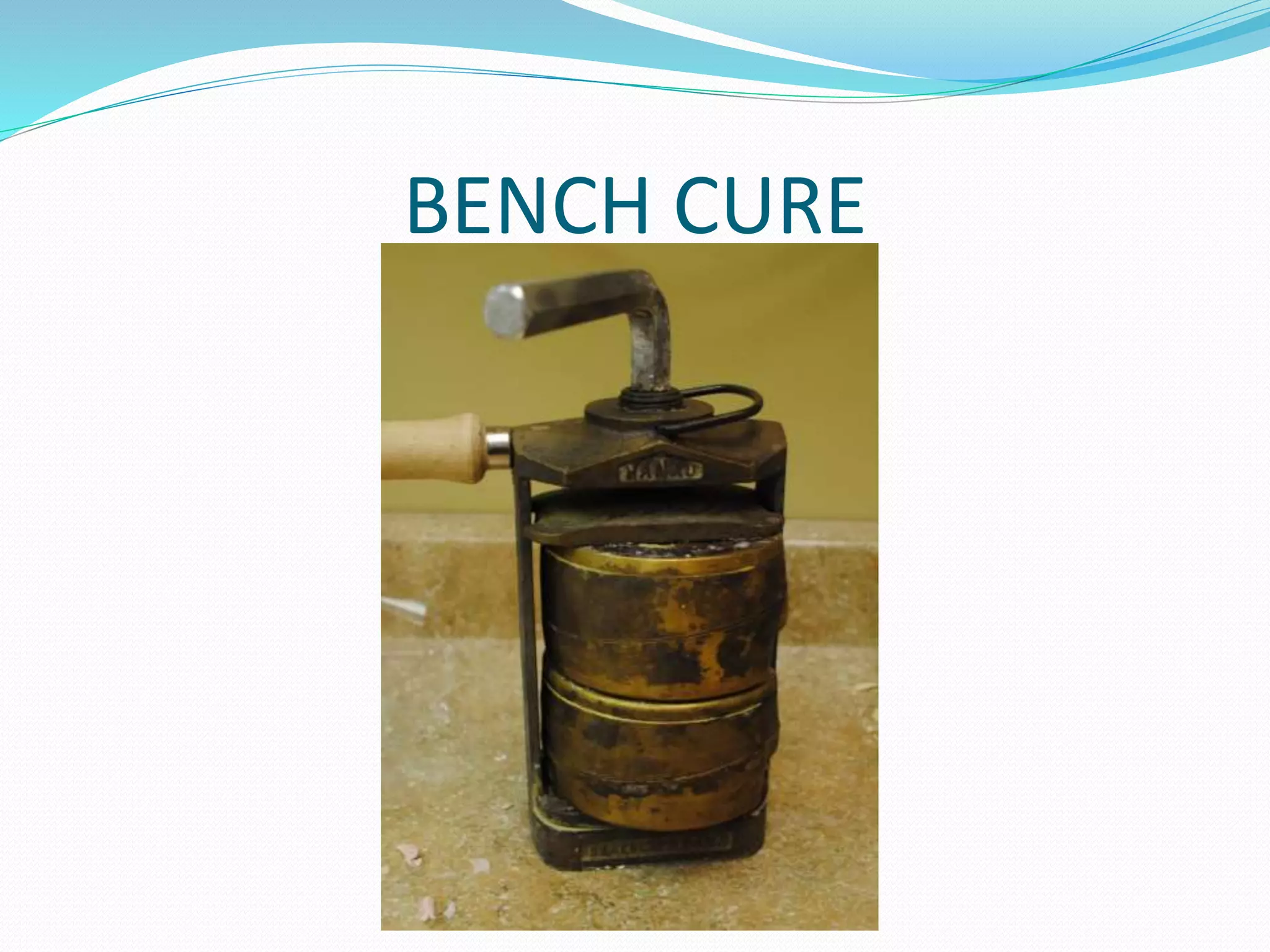

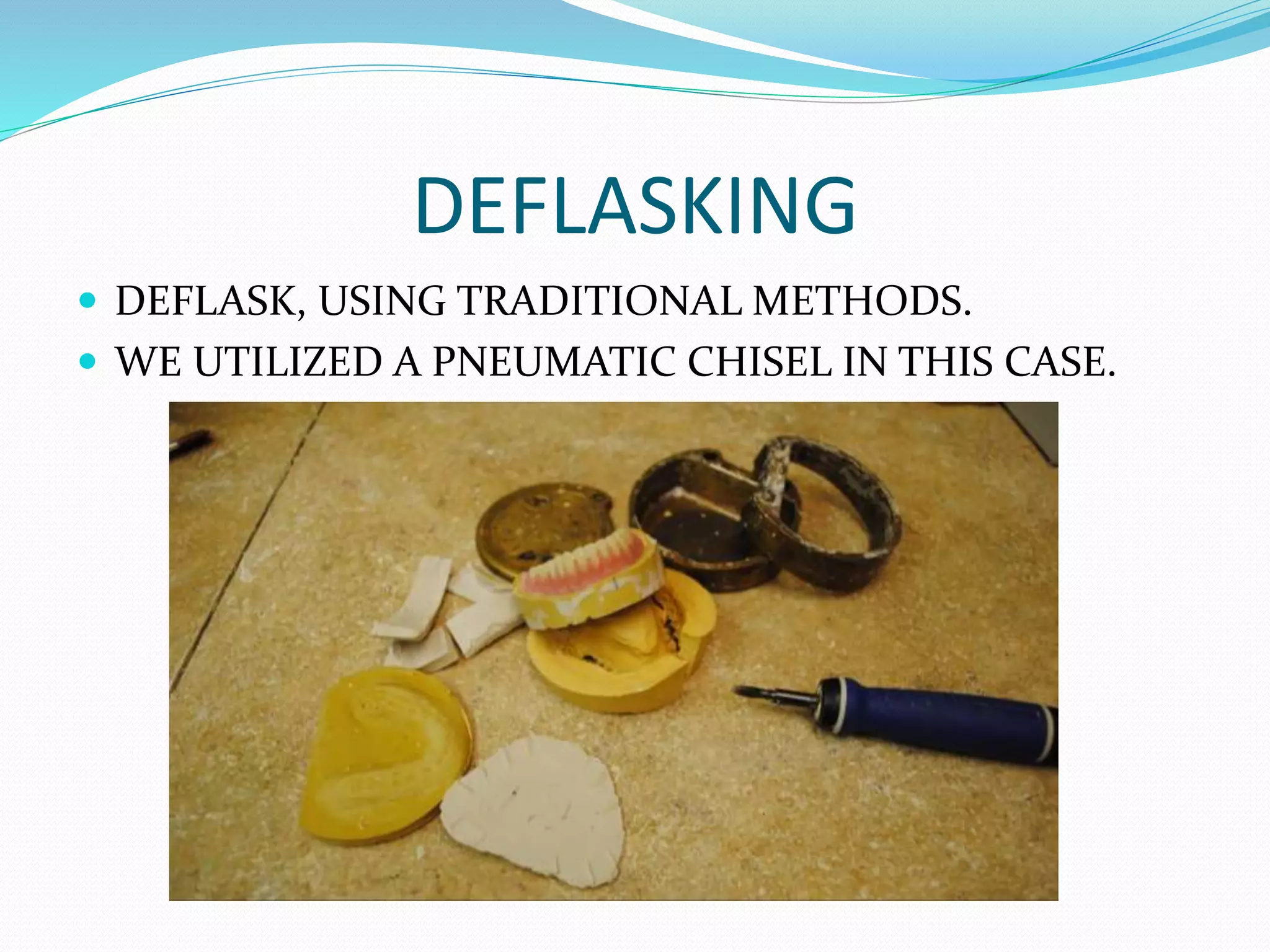

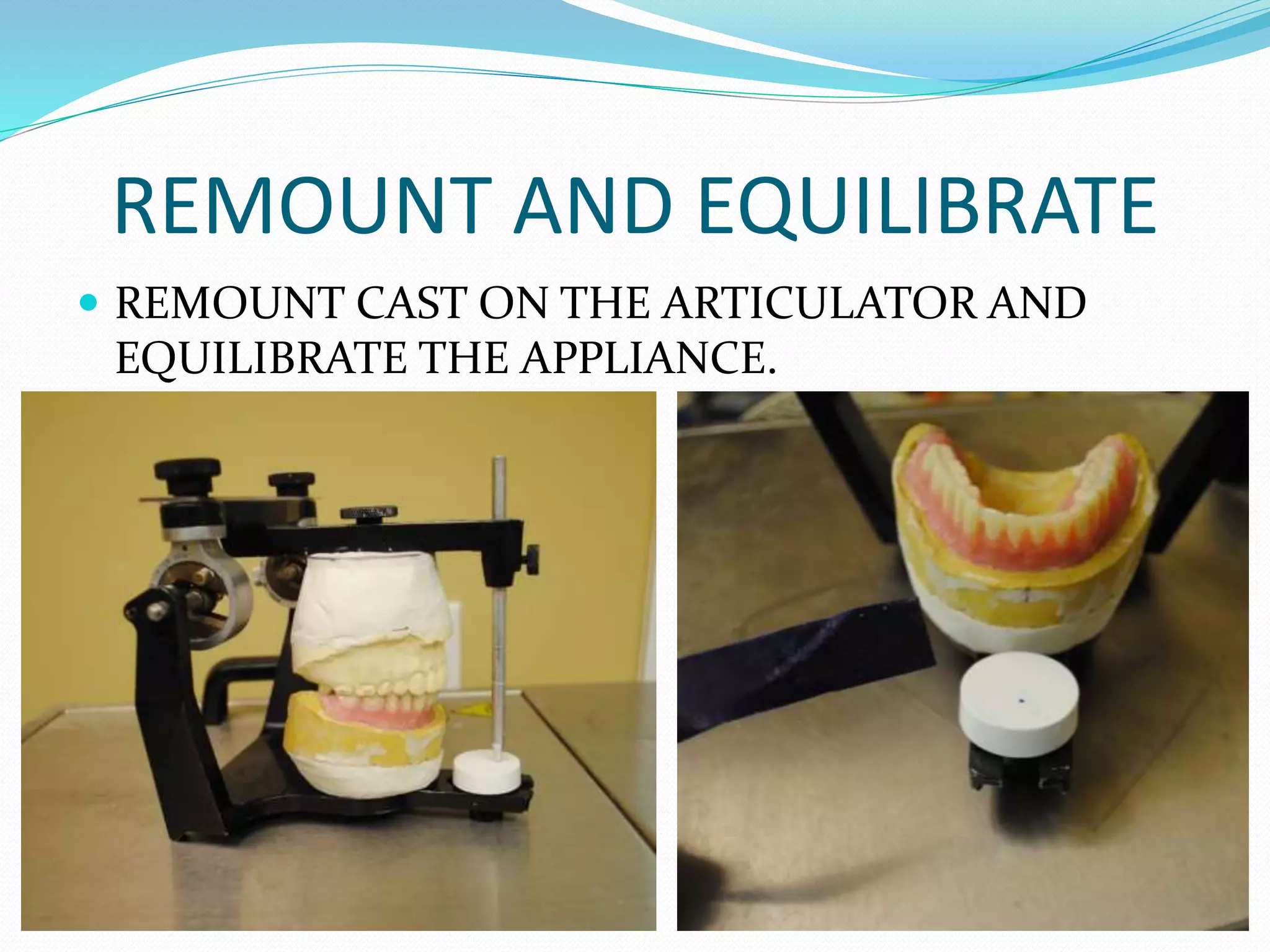

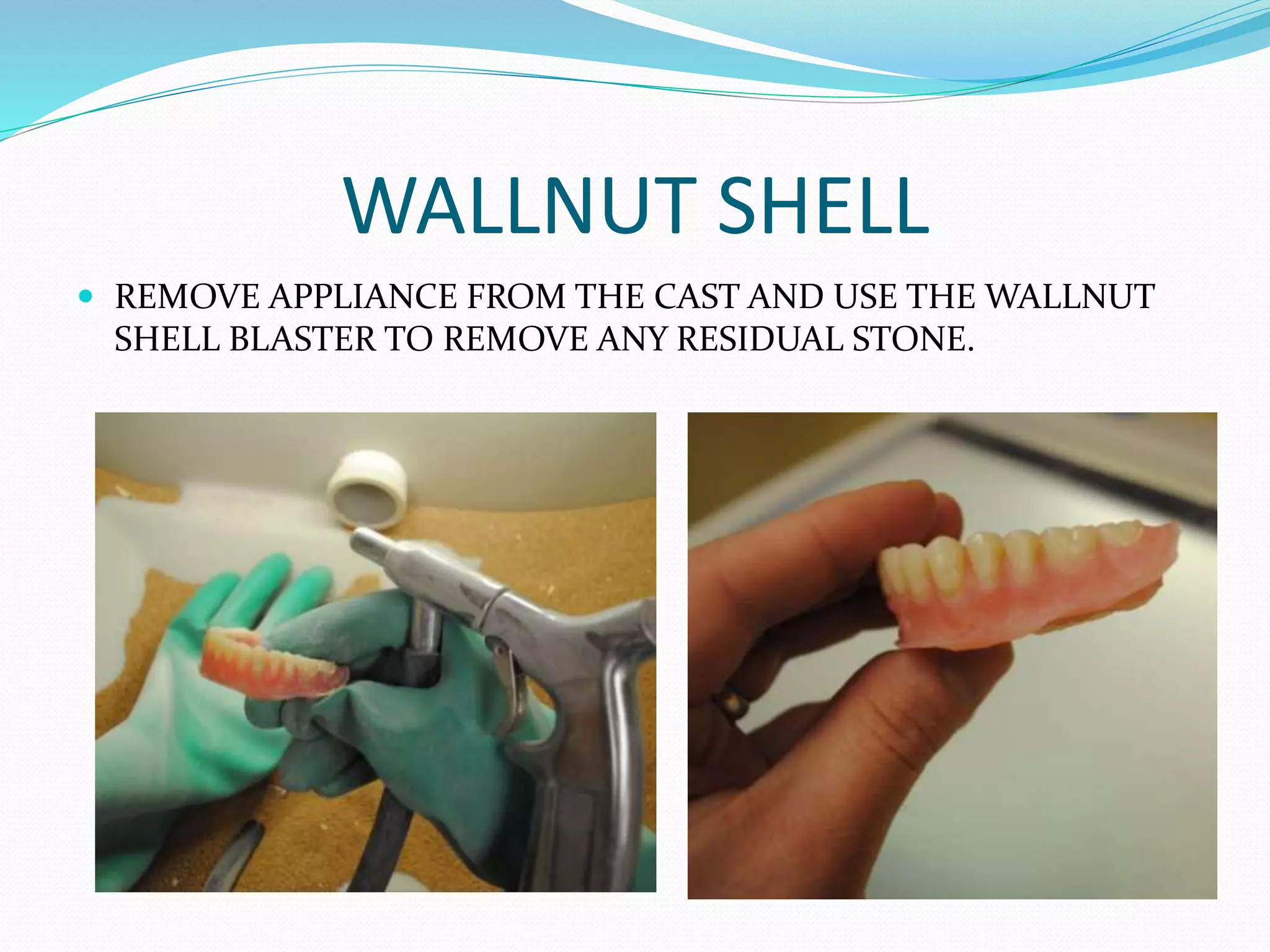

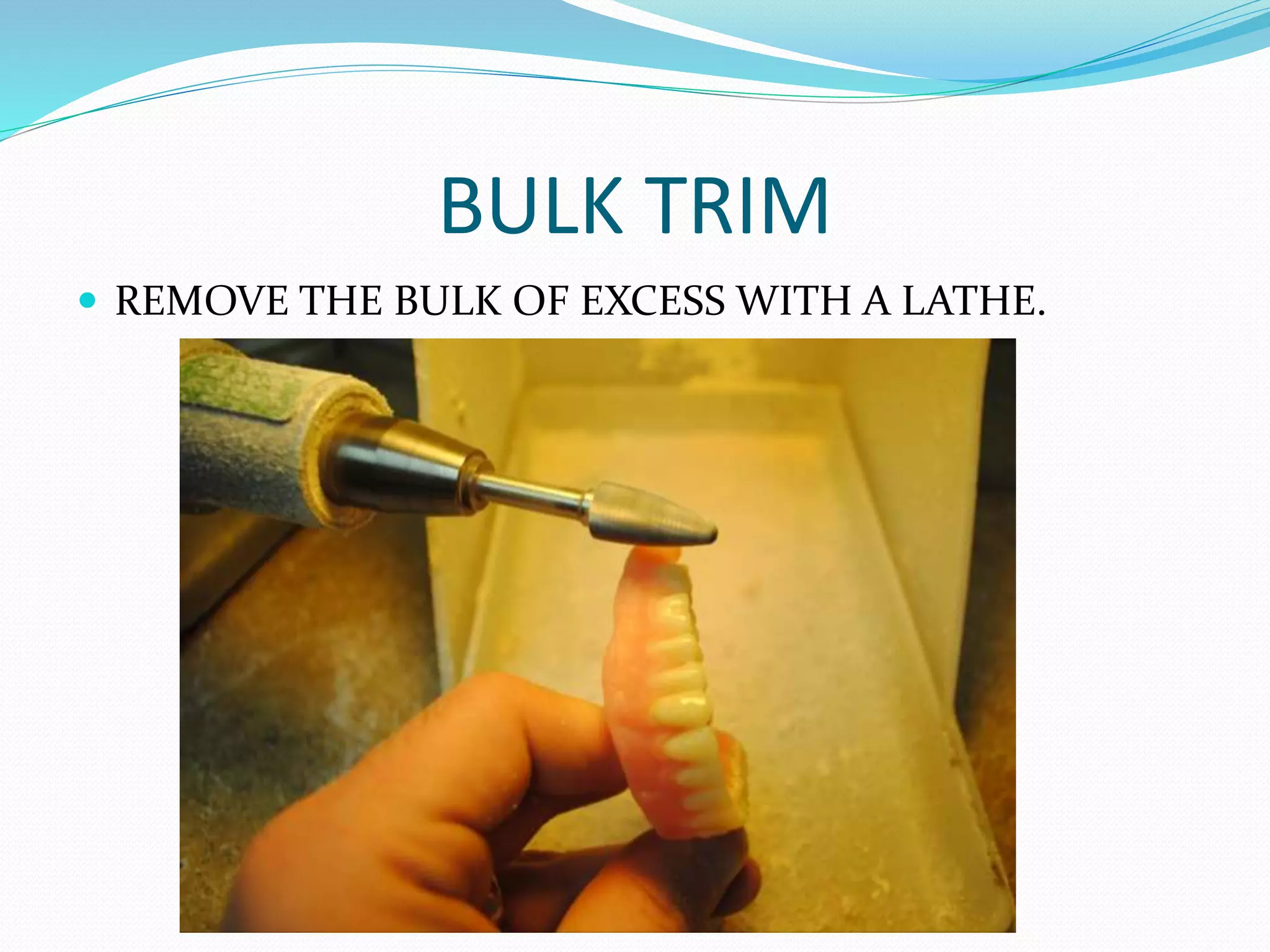

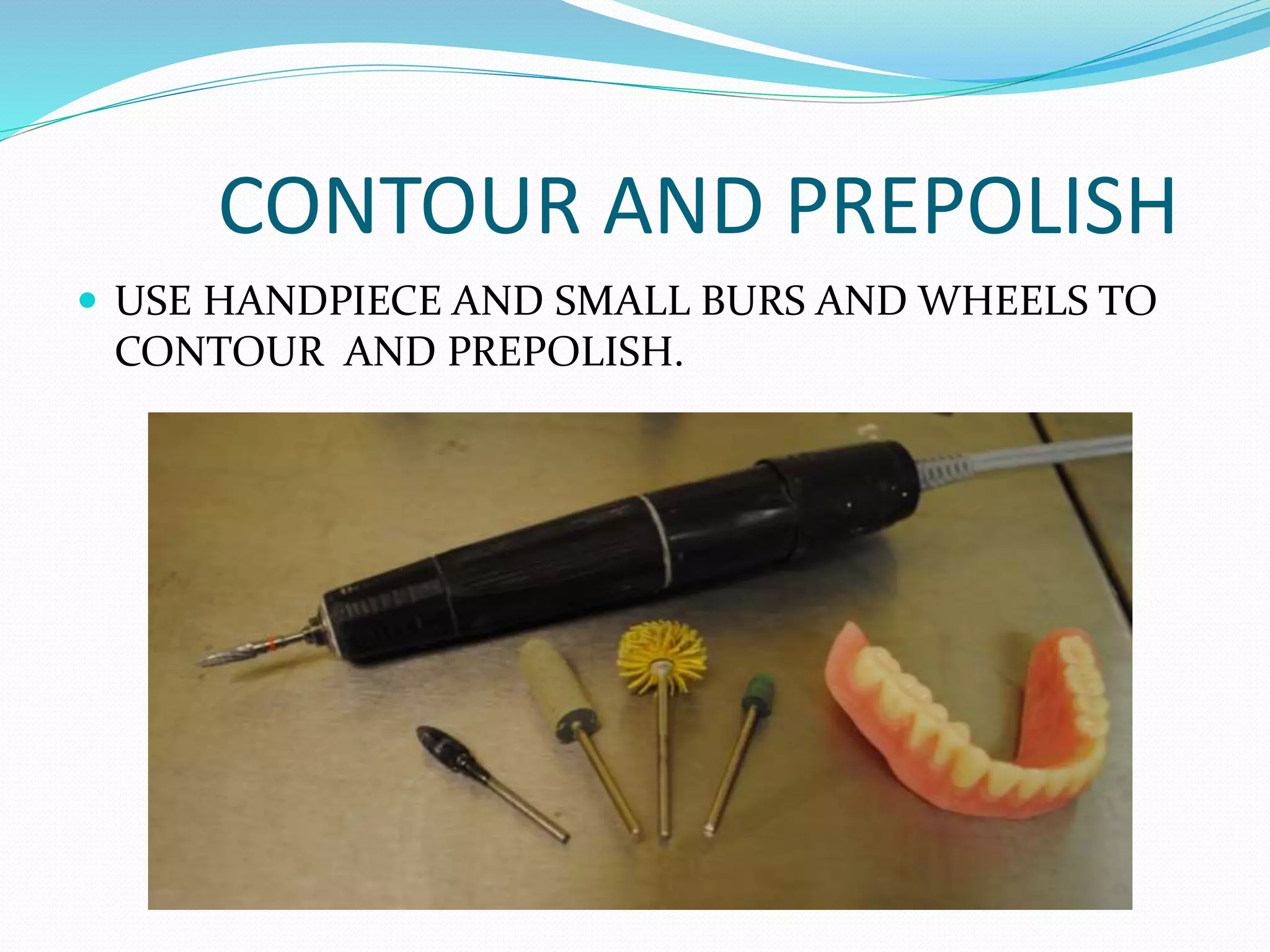

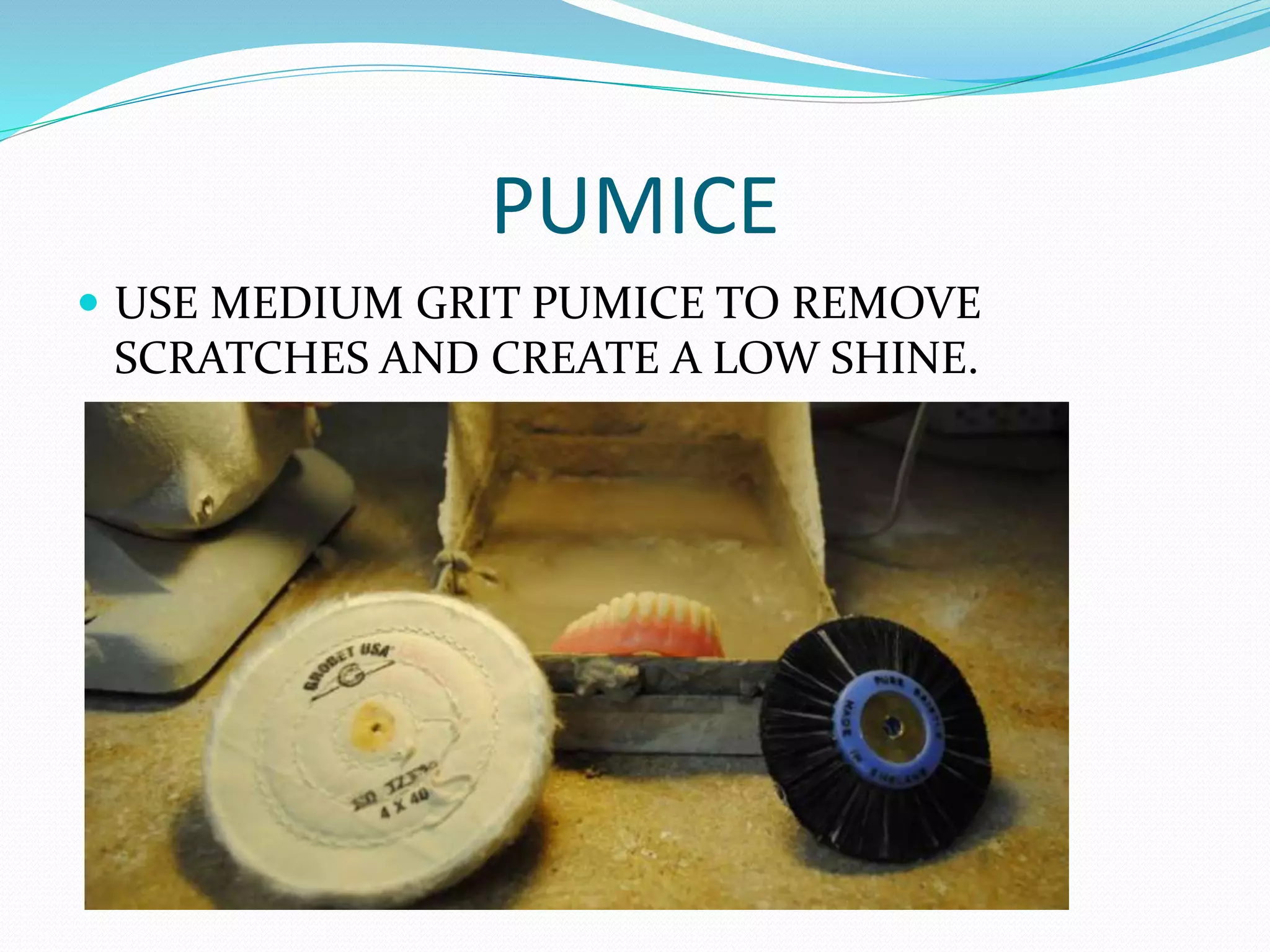

The document summarizes the steps taken to fabricate a new denture using the existing denture as a custom tray and bite registration. Key steps included: 1) taking an impression and pouring a master cast; 2) setting up the teeth and denture base on an articulator; 3) flasking, packing, and curing the acrylic; 4) deflasking, finishing, and polishing the new denture. The existing denture helped establish vertical dimension and bite registration to fabricate a replacement denture.