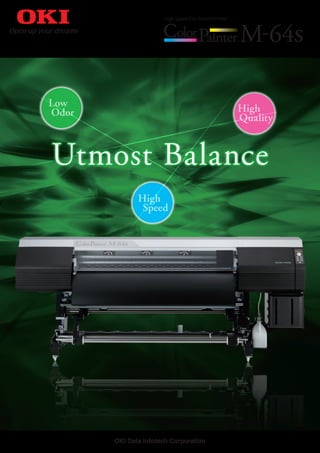

The ColorPainter M-64S is a high-speed eco-solvent printer utilizing low-odor SX inks that deliver a wide color gamut, high durability, and excellent outdoor performance. It features advanced technologies such as dynamic dot printing, automatic print adjustment, and a user-friendly software for managing print jobs, enhancing productivity and quality for signage applications. The printer's design supports uninterrupted high-volume printing with large-capacity ink cartridges and a robust media handling system.