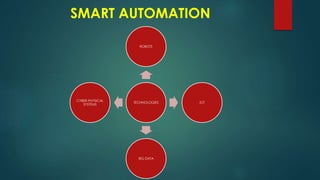

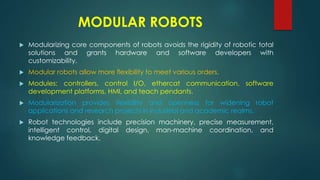

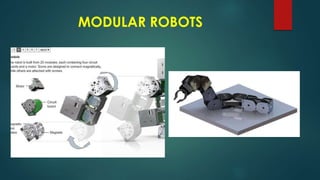

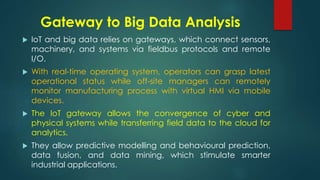

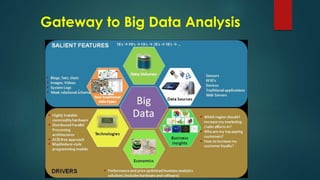

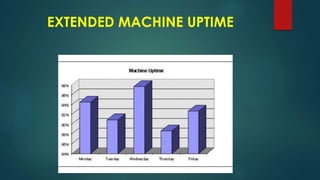

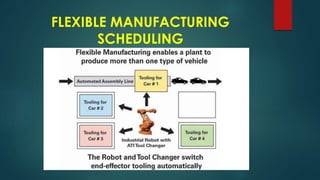

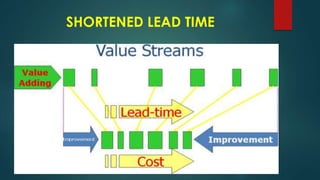

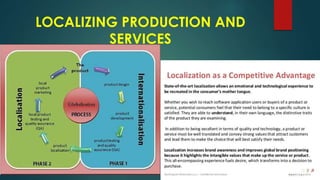

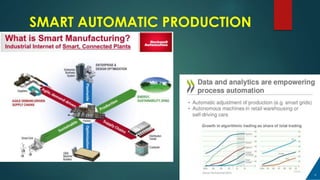

The document outlines 6 new strategies for Taiwan to address challenges of a shrinking workforce and competitive pressures: 1) enhancing flagship industries' smart supply chains, 2) encouraging startups, 3) localizing production, 4) achieving autonomy in key technologies, 5) cultivating technical talents, and 6) injecting industrial policy tools. It discusses using smart automation technologies like robots, IoT, big data, and cyber-physical systems to achieve goals like man-machine coordination, extended machine uptime, flexible scheduling, shortened lead times, and zero inventory.