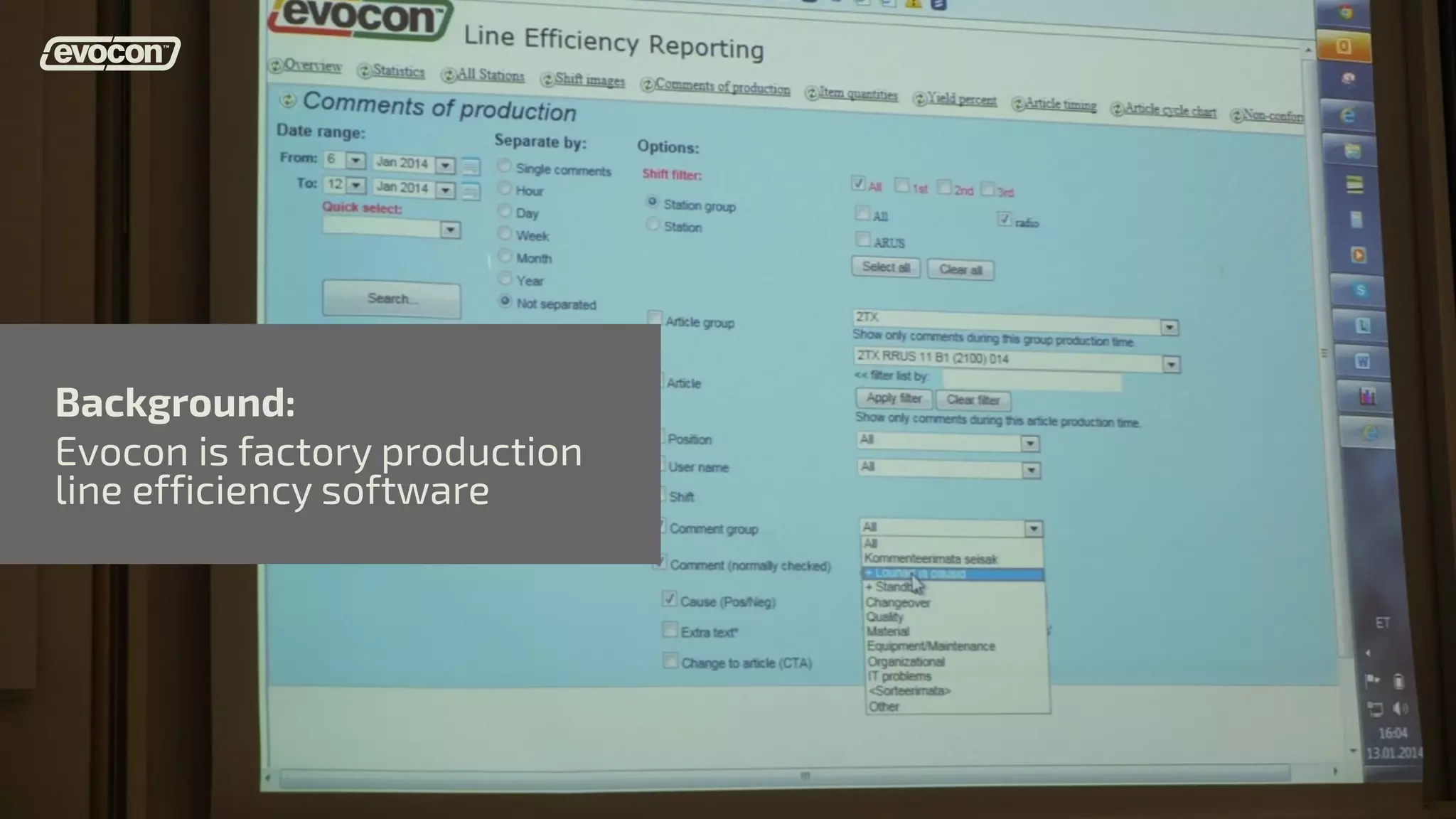

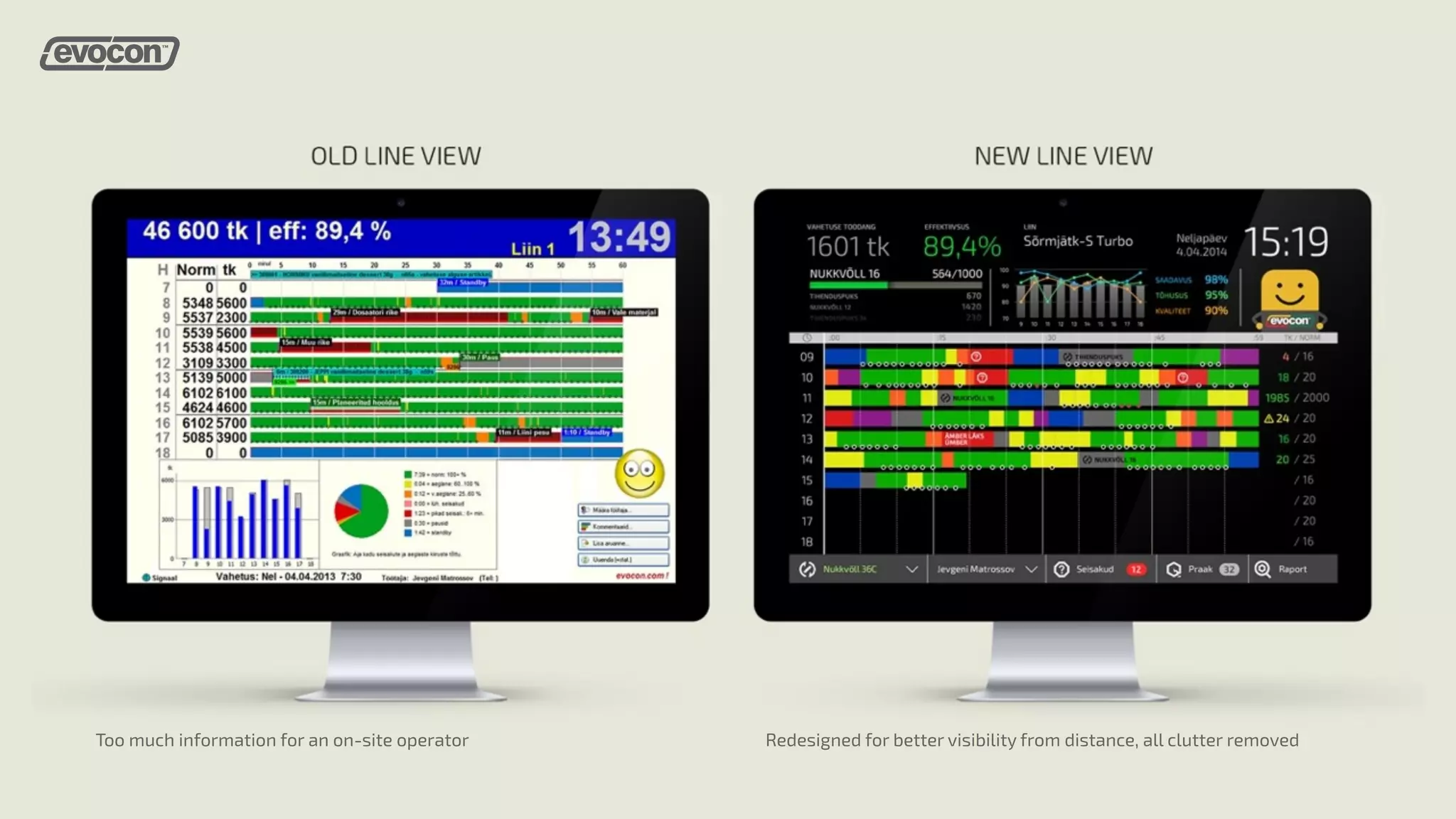

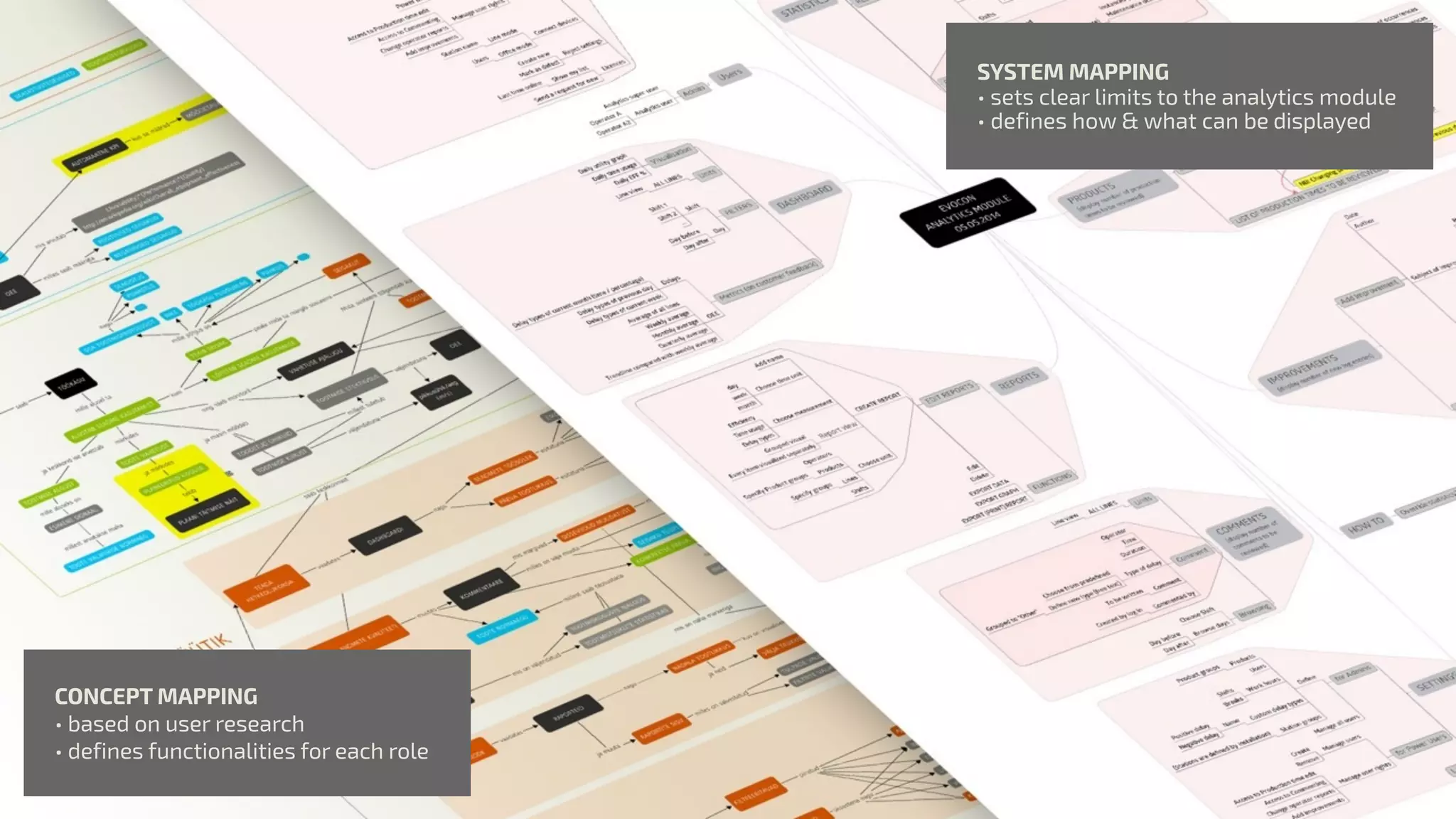

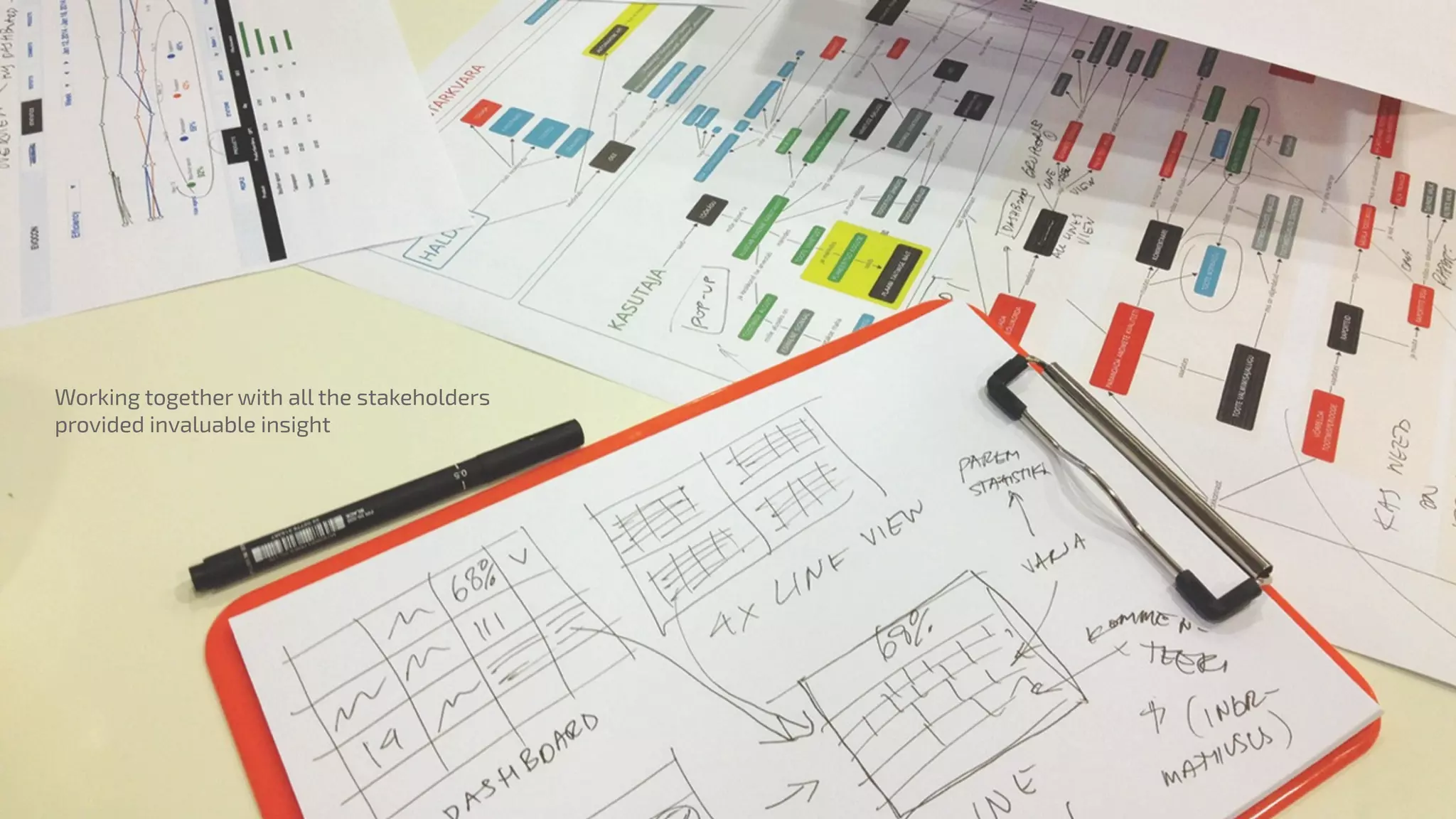

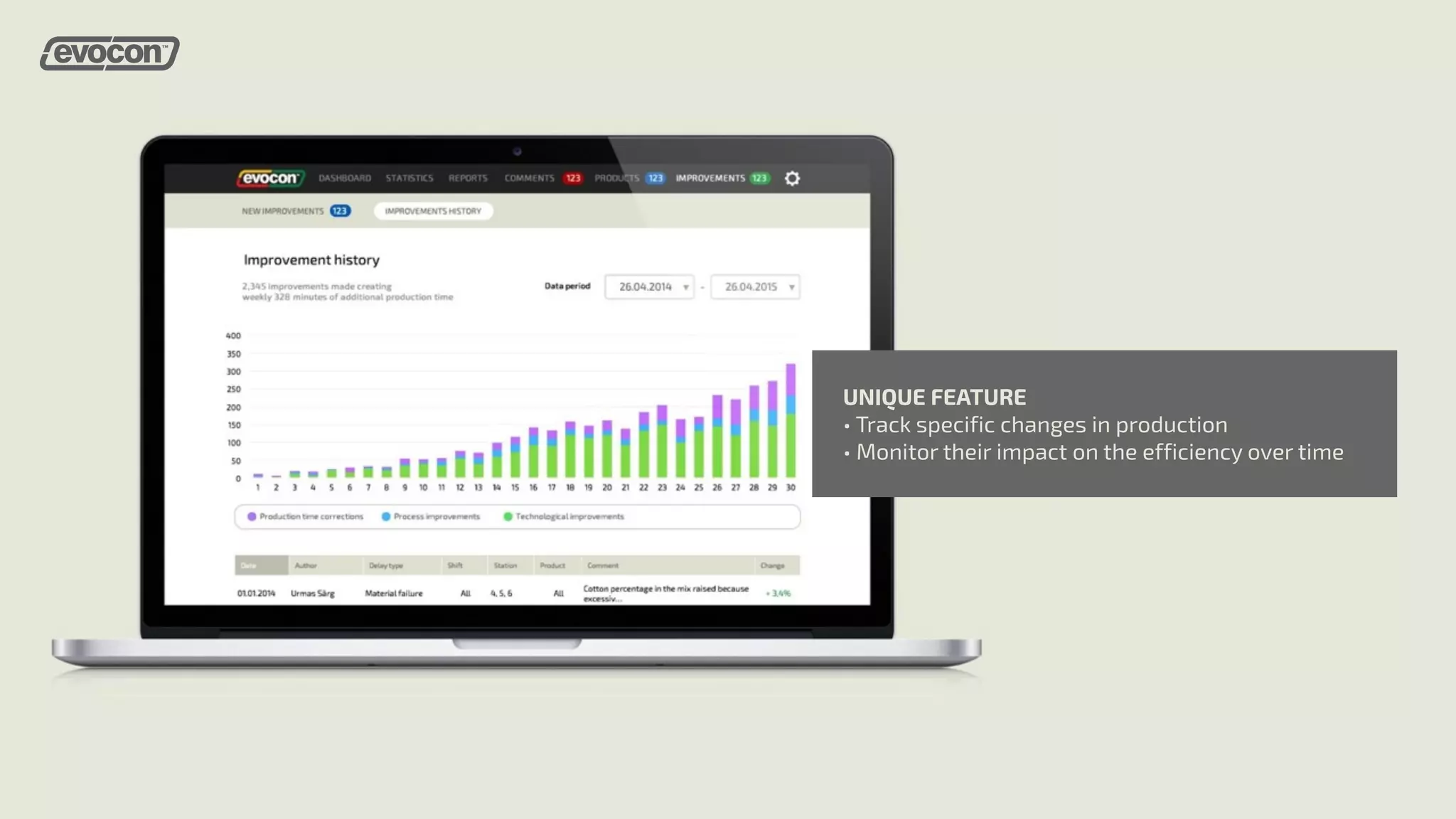

Evocon is a factory production line efficiency software that struggled with usability due to the need for constant developer support and complex systems for end users. The redesign process involved extensive user research, wireframing, and testing to create intuitive user interfaces that improve visibility and functionality for various user roles. Key achievements included enhanced service understanding, improved production routines, increased efficiency, and higher customer satisfaction.