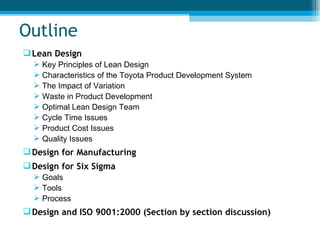

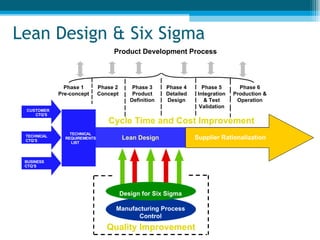

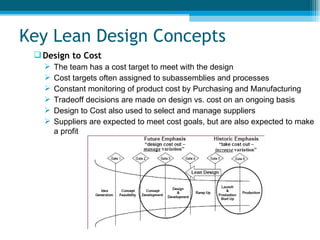

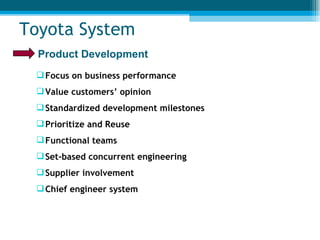

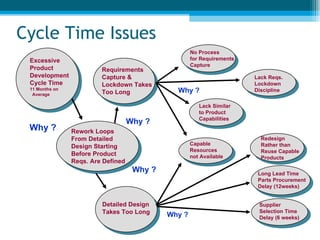

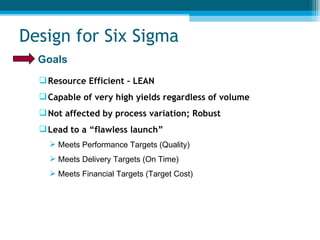

The document outlines key concepts of lean design and the Toyota product development system. It discusses the lean design process which includes 6 phases from concept to production. It identifies types of waste in product development like defects, excess inventory, unnecessary processing. The document also notes issues around long cycle times, cost, and quality in traditional design and how lean principles can help address these.